Method for preparing magnetic-induced discoloration polymeric fibers

A polymer fiber and magneto-induced technology, applied in fiber treatment, textile and papermaking, physical treatment, etc., can solve problems such as weak binding force, achieve good effect, simple operation, and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

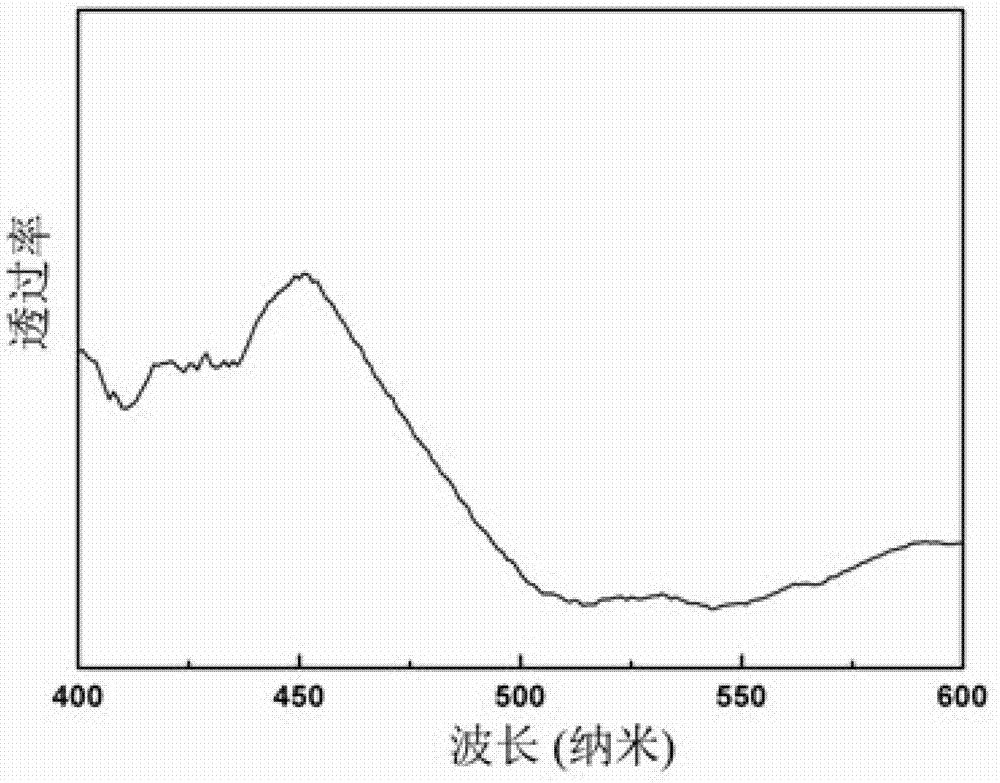

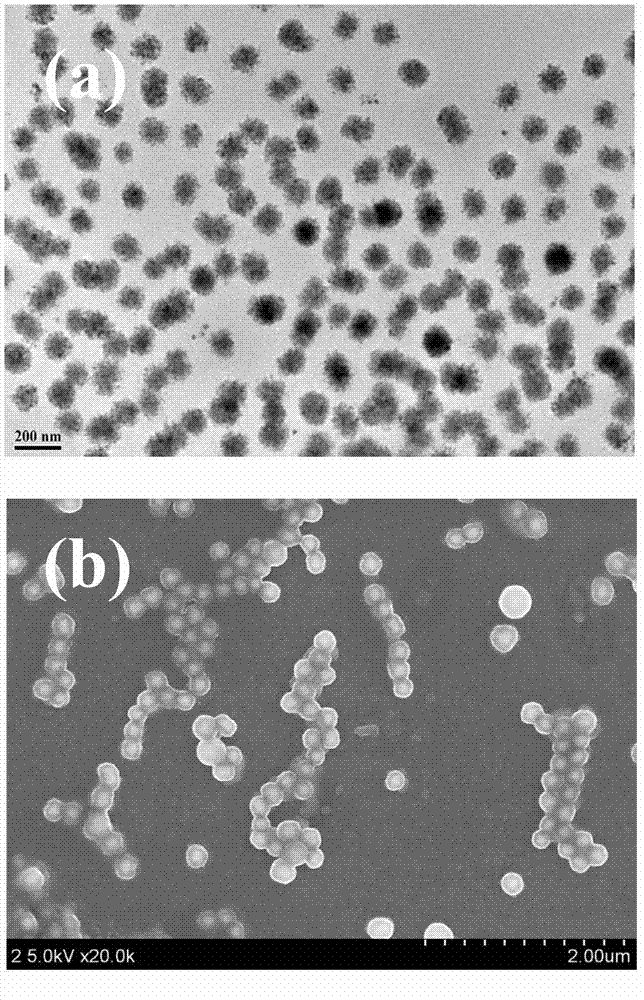

[0032] Prepare lotion I, the volume ratio of concentrated sulfuric acid, hydrogen peroxide, and distilled water is 4:1:20; lotion II, ammonia water, hydrogen peroxide, and distilled water = 1:4:20, soak the glass microtube and polymer fiber in lotion I Soak in 110°C for 30 minutes, rinse with deionized water, then soak the microchannel and glass fiber in lotion II for 30 minutes at 60°C, rinse with deionized water, and dry; at room temperature, Measure 0.5g ferrocene, measure 60mL acetone, 2.5mL hydrogen peroxide and place in a beaker, stir magnetically for 40 minutes at a stirring speed of 300rpm, put the reaction solution into the reaction kettle and adjust the filling degree to 4 / 5, in React at 220°C for 60 hours, cool naturally to room temperature, centrifuge the product, and wash to obtain Fe 3 o 4 nanospheres, and disperse them in 30mL of acetone solution; the above solution is uniformly mixed with polyethylene glycol diacrylate (PEGDA) in a volume ratio of 4:1, and pla...

Embodiment 2

[0034] Prepare lotion I, the volume ratio of concentrated sulfuric acid, hydrogen peroxide, and distilled water is 4:1:20; lotion II, ammonia water, hydrogen peroxide, and distilled water = 1:4:20, soak the glass microtube and polymer fiber in lotion I Soak in 120°C for 30 minutes, rinse with deionized water, then soak the microchannel and glass fiber in lotion II for 30 minutes at 70°C, rinse with deionized water, and dry; at room temperature, Measure 0.7g of ferrocene, measure 52.5mL of acetone and 2.5mL of hydrogen peroxide into a beaker, stir magnetically for 25 minutes at a stirring speed of 500rpm, put the reaction solution into the reactor and adjust the filling degree to 3 / 4, React at 200°C for 72 hours, cool naturally to room temperature, centrifuge the product and wash to obtain Fe 3 o 4 nanospheres, and disperse them in 30mL of acetone solution; the above solution is uniformly mixed with polyethylene glycol diacrylate (PEGDA) in a volume ratio of 2:1, and placed in...

Embodiment 3

[0036] Prepare lotion I, the volume ratio of concentrated sulfuric acid, hydrogen peroxide, and distilled water is 4:1:20; lotion II, ammonia water, hydrogen peroxide, and distilled water = 1:4:20, soak the glass microtube and polymer fiber in lotion I Soak at 130°C for 30 minutes, rinse with deionized water, then soak the microchannel and glass fiber in lotion II at 80°C for 30 minutes, rinse with deionized water, and dry; at room temperature, Measure 0.3g of ferrocene, measure 37.5mL of acetone and 2.5mL of hydrogen peroxide into a beaker, stir magnetically for 10 minutes at a stirring speed of 800rpm, put the reaction solution into the reactor and adjust the filling degree to 1 / 2, Reaction at 180°C for 84 hours, naturally cooled to room temperature, the product was centrifuged and washed to obtain Fe 3 o 4 nanospheres, and disperse them in 30mL of acetone solution; the above solution is uniformly mixed with polyethylene glycol diacrylate (PEGDA) at a volume ratio of 1:4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com