Metal support flexible board, metal support carrier tape for tape automated bonding using same, metal support flexible circuit board for mounting led, and copper foil-laminated metal support flexible circuit board for forming circuit

A technology that supports flexible and circuit substrates. It is used in circuit substrate materials, circuits, and printed circuits. It can solve problems such as foaming and insufficient insulation performance, and achieve the effect of easy, simple cost, and low curling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

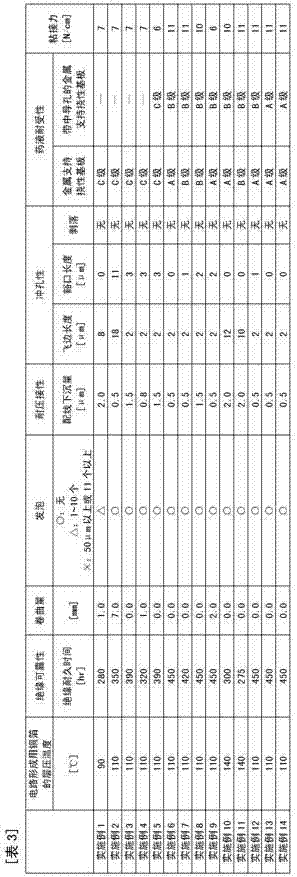

Examples

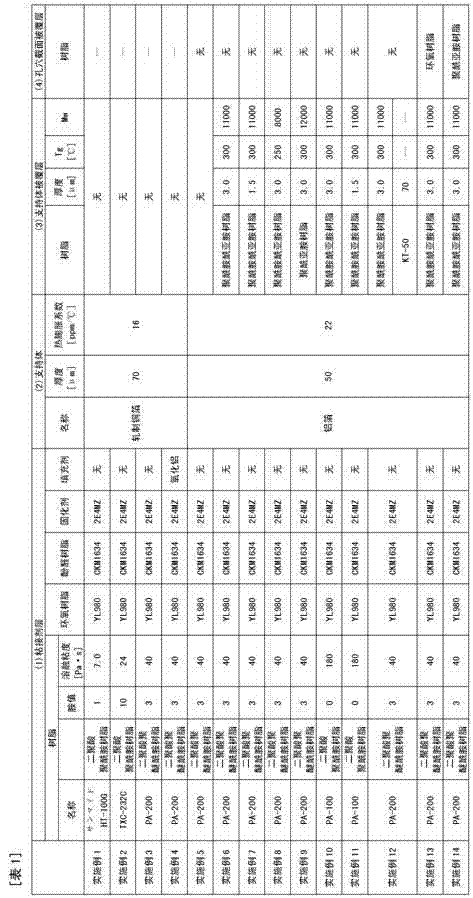

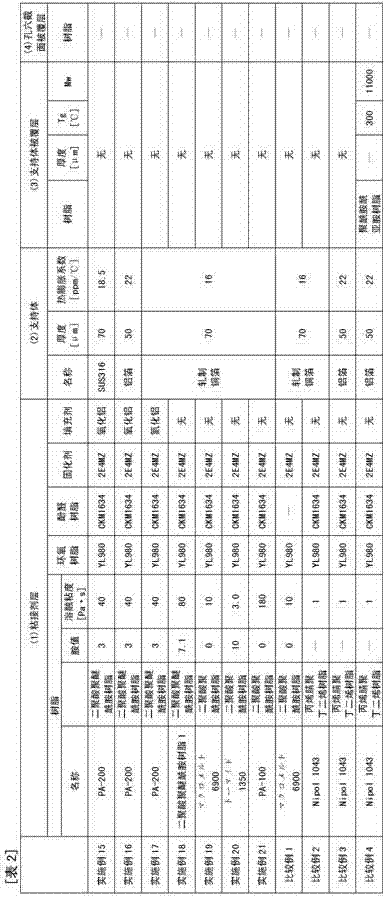

Embodiment 1

[0083] (a) Preparation of adhesive layer

[0084] To 100 parts by weight of (A) dimer acid polyamide resin ("Sunmide (サンマイド)" (registered trademark) HT-100G, Air Products Japan, Inc. (エアープロダクツジャパン company), amine value 1, melt viscosity 7.0 Pa·s), 50 parts by weight of (B) phenolic resole (CKM1634 Showa Polymer Co., Ltd.), 80 parts by weight of (C) epoxy resin ("Epikote (エピコート)" (registered trademark) YL980, Japan Epoxy Resins Co., Ltd. (manufactured by J.P.S. Resins Co., Ltd.), 2 parts by weight of (D) curing accelerator (2-ethyl-4-methylimidazole (2E4MZ), manufactured by Tokyo Chemical Industry Co., Ltd.), ethanol / Toluene mixed solvent (mixing weight ratio ethanol 1: toluene 4) was stirred and mixed at 30°C to prepare an adhesive composition with a solid content concentration of 25% by weight. The adhesive composition was coated with a bar coater on (5) a protective film (a polyethylene terephthalate film with a thickness of 25 μm with a silicone release agent ("FILMBYNA" man...

Embodiment 2

[0090] Except when preparing the adhesive layer sheet, 100 parts by weight of (A) dimer acid polyamide resin ("Tohmide (トーマイド)" (registered trademark) TXC-232C, Fuji Chemicals is used as components (A) to (D) Made by Kogyo Co., Ltd., amine value 10.0, melt viscosity 24.0Pa·s), 50 parts by weight of (B) resole resin (CKM1634 made by Showa Polymer Corporation), and 80 parts by weight of (C) epoxy resin ("Epikote ( エピコート)” (registered trademark) YL980, Japan Epoxy Resins Co., Ltd. (manufactured by Japan Epoxy Resins Co., Ltd.), 2 parts by weight of (D) curing accelerator (2-ethyl-4-methylimidazole (2E4MZ)) , Tokyo Chemical Industry Co., Ltd.), the preparation was carried out in the same manner as in Example 1, and the evaluations described in (1) to (7) above were performed.

Embodiment 3

[0092] Except when preparing the adhesive layer sheet, 100 parts by weight of (A) dimer acid polyether amide resin ("Tohmide (トーマイド)" (registered trademark) PA-200, Fujifilm is used as components (A) to (D) Produced by Kasei Kogyo Co., Ltd., amine value 3, melt viscosity 40.0 Pa·s), 50 parts by weight of (B) resole resin (CKM1634, Showa Polymer Co., Ltd.), and 80 parts by weight of (C) epoxy resin ("Epikote (エピコート)" (registered trademark) YL980, Japan Epoxy Resins Co., Ltd. (manufactured by Japan Epoxy Resins Co., Ltd.), 2 parts by weight of (D) curing accelerator (2-ethyl-4-methylimidazole (2E4MZ) ), Tokyo Chemical Industry Co., Ltd.), the preparation was carried out in the same manner as in Example 1, and the evaluations described in (1) to (7) above were performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com