Preparation method of porous ceramic pipe with gradient through hole structure

A technology of porous ceramics and through-holes, applied in the field of porous ceramics, can solve the problems of low strength, easy to cause pollution, unstable structure, etc., and achieve the effects of high strength, easy cleaning and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

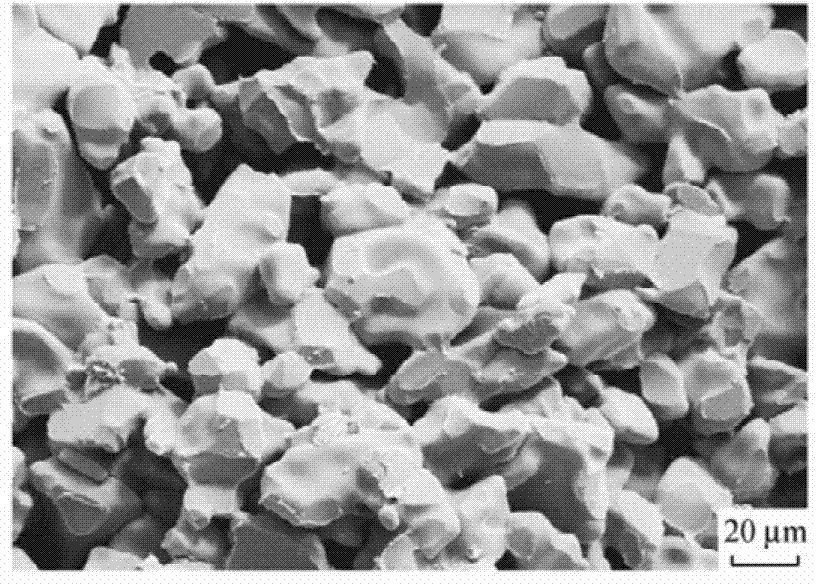

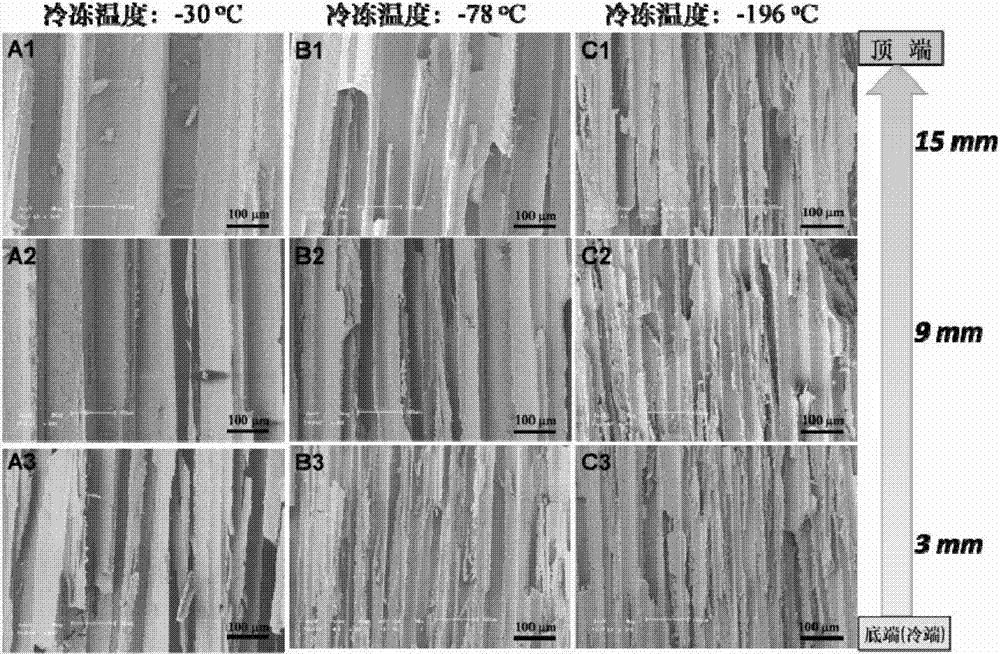

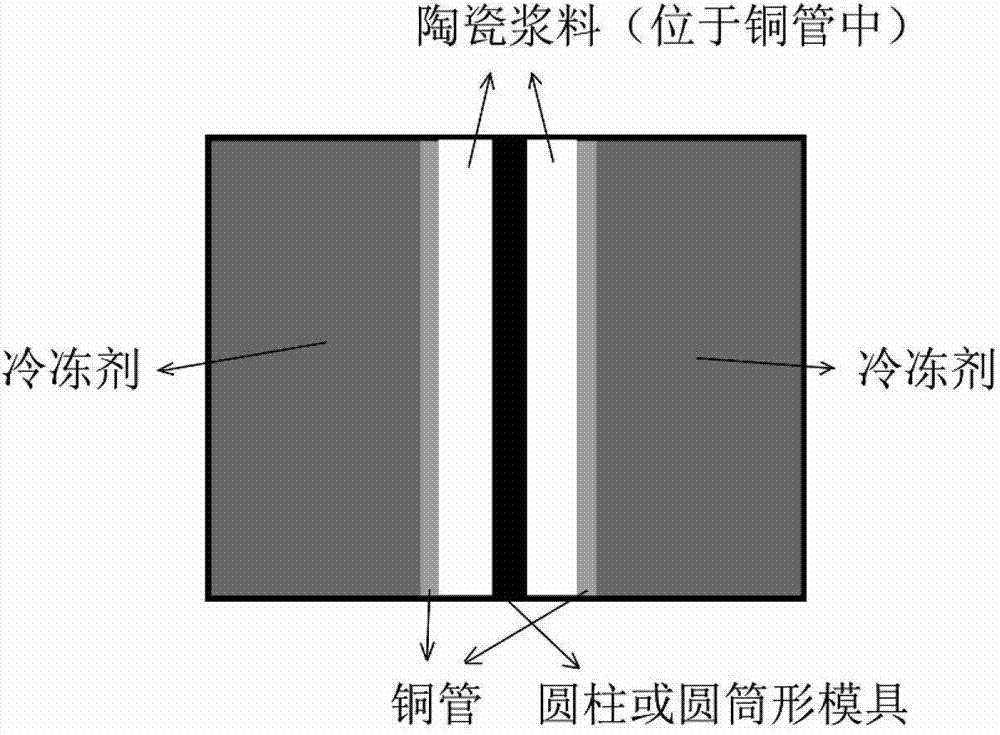

[0048] Example 1: Heat tert-butanol to 50°C to make it liquid, add 3.2g DISPER-BYK163 and 1.6g PVP to 93.6ml tert-butanol (accounting for 1% and 0.5% of ceramic powder respectively ), stirred for 10 minutes, then added 317.6g of alumina powder, and ball milled for 4 hours to prepare a ceramic slurry with a solid content of 40vol%. Then pour the slurry into the copper tube sealed at the bottom. The size of the copper tube is 60mm in outer diameter, 3mm in thickness, and 100mm in length. A plastic hose with an outer diameter of 30mm is inserted in the middle of the slurry as a mold. tube bottom. Cover the outside of the copper tube with dry ice and freeze for 1.5 hours. Remove copper pipe and mold then, the body that freezing obtains is placed in freeze drier and vacuumizes 6 hours, and temperature is set to subzero 50 ℃. The dried green body was put into a muffle furnace and raised to 1700°C at a rate of 2°C / min, and kept for 1h. Finally, an alumina porous ceramic tube with ...

Embodiment 2

[0049] Example 2: Heat tert-butanol to 52°C to make it liquid, add 2.8g DISPER-BYK164 and 1.9g PEG4000 to 109.2ml tert-butanol (1.5% and 1% by weight of ceramic powder respectively ), stirred for 10 minutes, then added 189.6g of mullite powder, and milled for 3 hours to prepare a ceramic slurry with a solid content of 30vol%. Then the slurry is poured into a plastic mold with a closed bottom. The inner diameter of the mold is 60 mm, and a copper tube is inserted in the middle of the slurry. The size of the copper tube is 30 mm in outer diameter, 2.5 mm in thickness, and 100 mm in length. Add 40ml of refrigerated ethanol with a temperature of about -40°C into the copper tube, keep adding dry ice to keep this temperature, and freeze for 1 hour. Remove copper pipe and mold then, and the green body obtained by freezing is placed in freeze drier and vacuumizes for 10 hours, and temperature is set to subzero 50 ℃. The dried green body was put into a muffle furnace and raised to 145...

Embodiment 3

[0050] Embodiment three: tert-butanol is heated to 50 DEG C so that it becomes liquid, and 2.1g DISPER-BYK167 and 1.6g gum arabic are added in 124.8ml tert-butanol (accounting for the proportion of ceramic powder is respectively 2% and 1.5 %), stirred for 10 minutes, then added 107.6g of cordierite powder, and milled for 5 hours to prepare a ceramic slurry with a solid content of 20vol%. Then pour the slurry into the copper tube sealed at the bottom. The size of the copper tube is 50mm in outer diameter, 3mm in thickness, and 100mm in length. A plastic hose with an outer diameter of 30mm is inserted in the middle of the slurry as a mold. tube bottom. The outside of the copper tube is covered with dry ice, then filled with frozen alcohol at a temperature of about -50°C, and frozen for 2 hours. Remove copper tube and mold then, and the green body that freezing is obtained is placed in freeze drier and vacuumizes 12 hours, and temperature is set to subzero 50 ℃. The dried green...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com