Method for separating and purifying chenodeoxycholic acid from duck gall

A technique for chenodeoxycholic acid and duck bile is applied in the field of separation and purification of chenodeoxycholic acid, which can solve the problems of inability to obtain chenodeoxycholic acid, and achieve the effect of improving extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

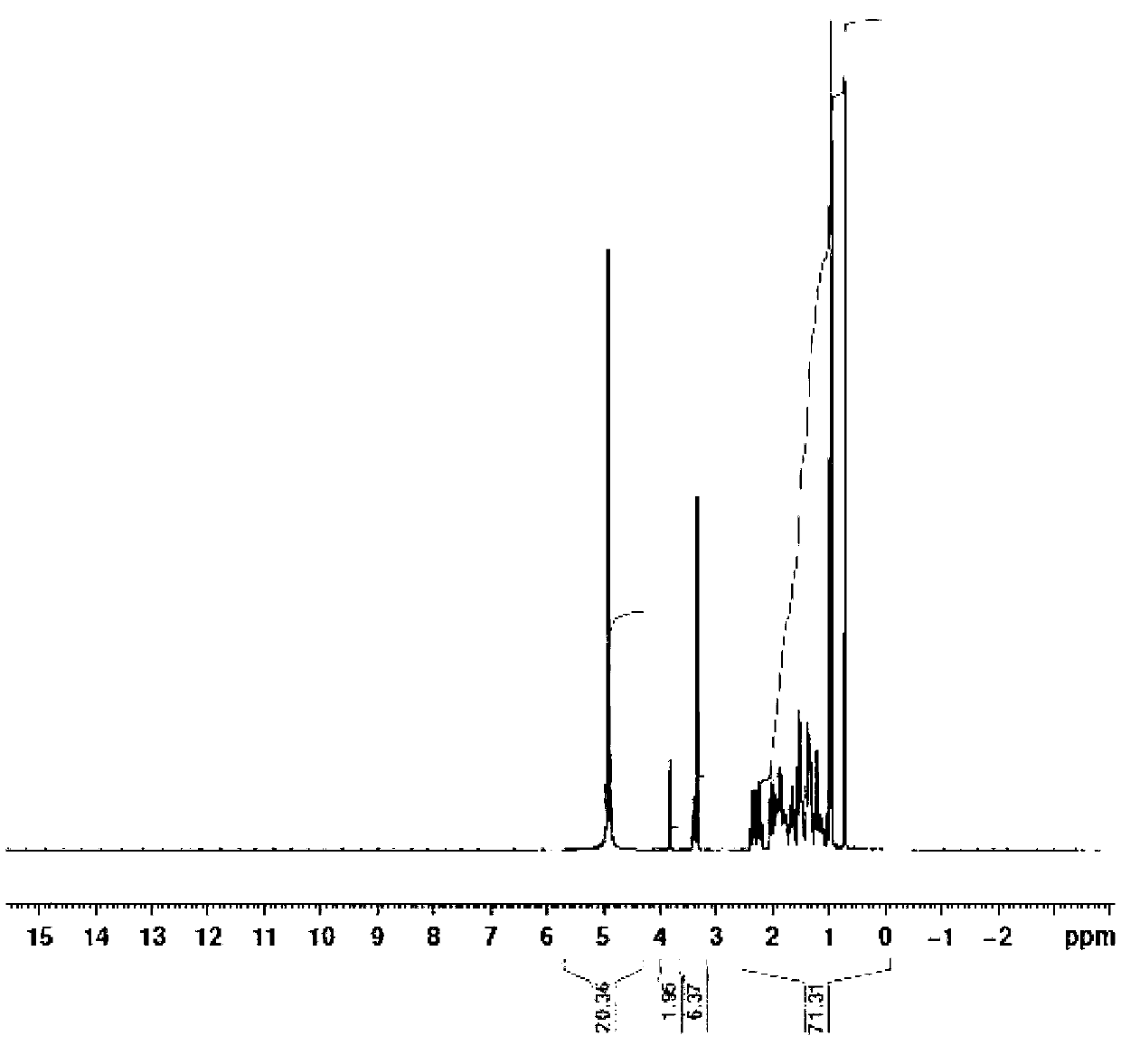

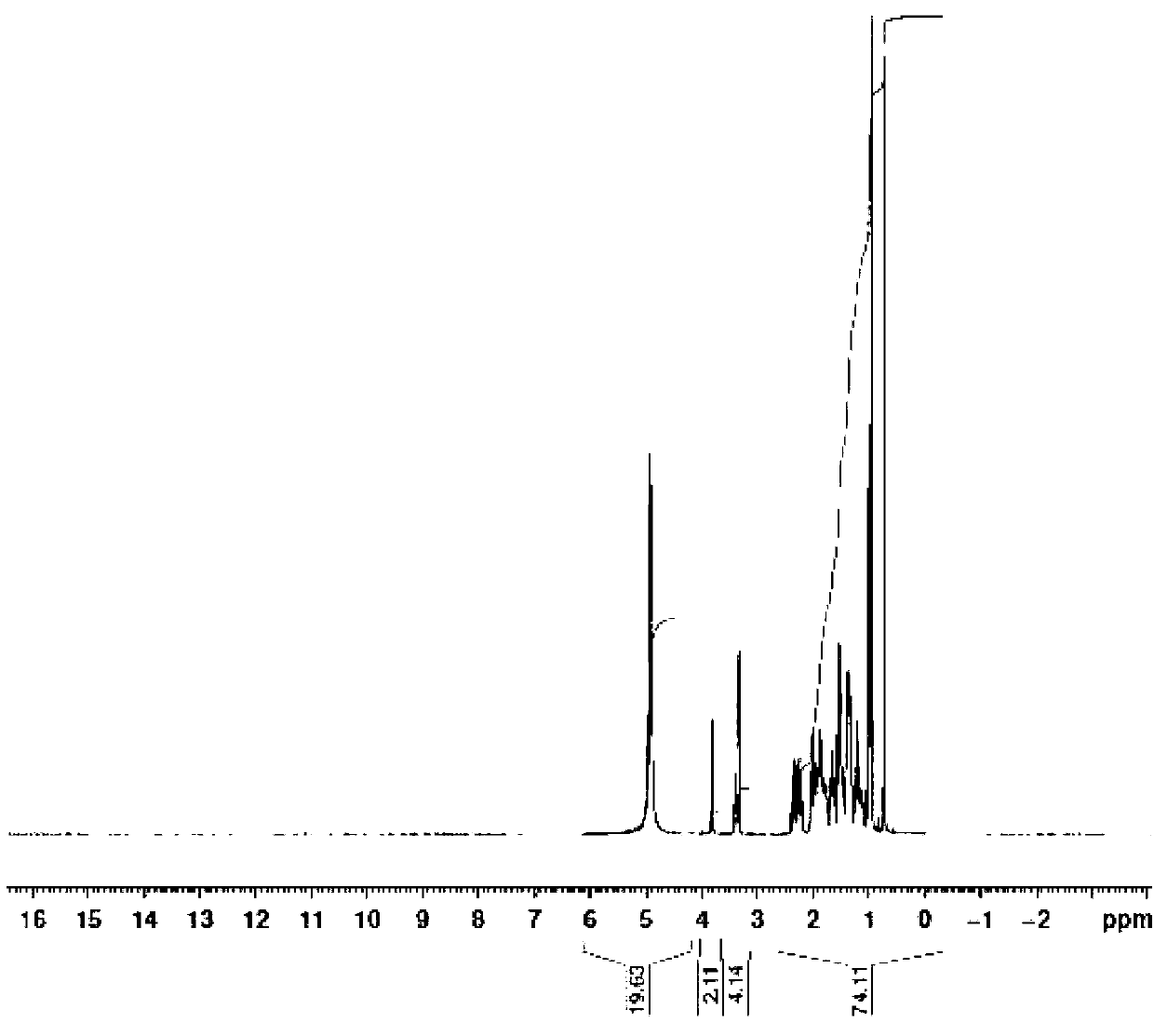

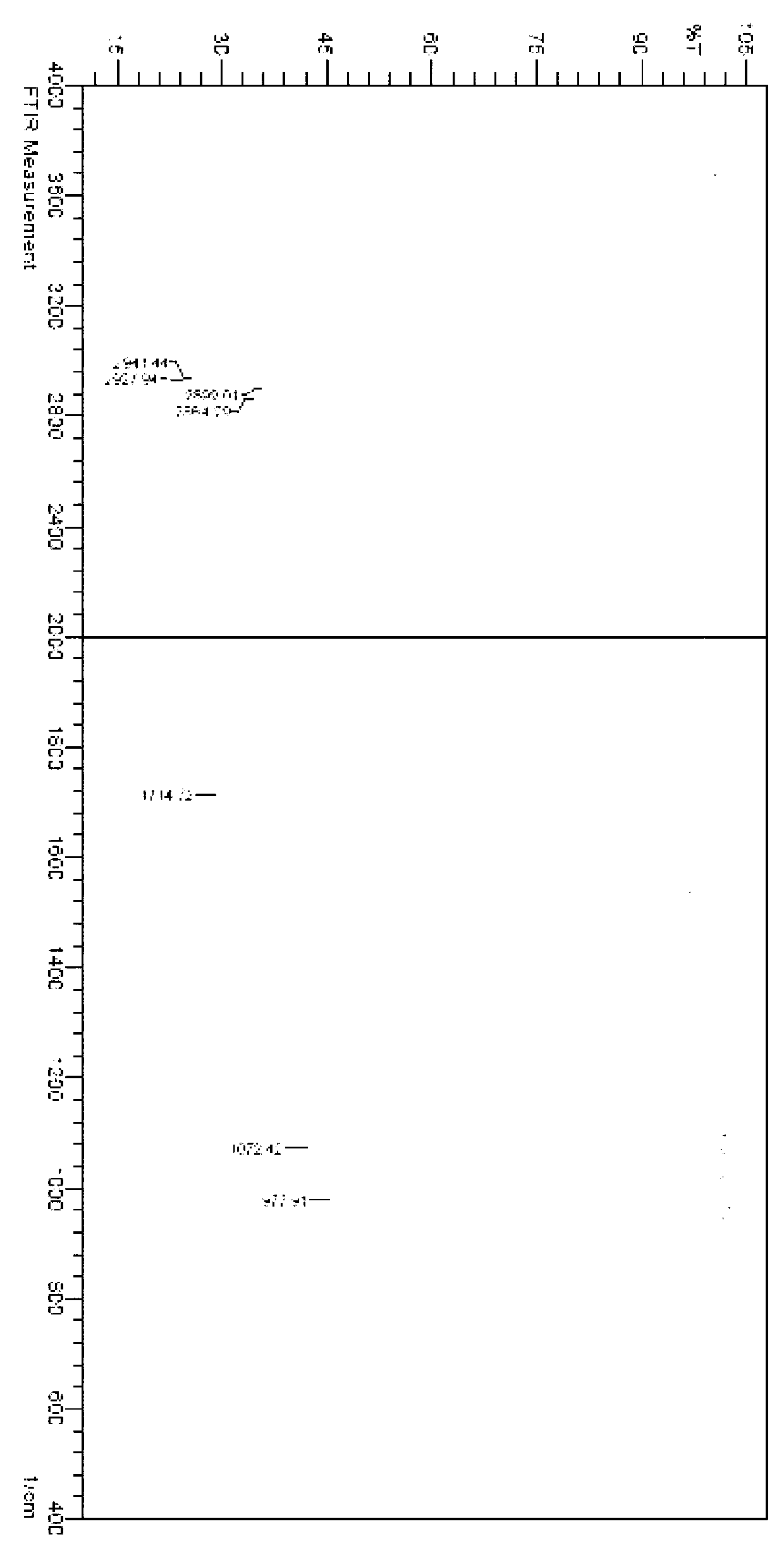

Image

Examples

Embodiment 1

[0028] Embodiment 1 prepares duck gall paste crude product from duck gall

[0029] Take 50kg of fresh duck bile (volume 50L) and put it in a stainless steel reaction kettle, add sodium hydroxide according to the amount of bile 50g / L, that is, add 2.5kg sodium hydroxide, heat and boil for 24 hours for saponification, and the mass percentage is 38 % concentrated hydrochloric acid to adjust the pH to 2, crystallize to obtain about 5 kg of brown paste, dissolve the paste with 50 kg of ethanol, add 0.5 kg of activated carbon to reflux for decolorization for 2 hours, filter to remove activated carbon, evaporate and concentrate to recover ethanol, and concentrate to obtain Duck gall paste crude product 5kg.

Embodiment 2

[0030] Embodiment 2 Calcium salt method prepares chenodeoxycholic acid crude product

[0031] 100kg of fresh duck bile is placed in a stainless steel reaction kettle, and sodium hydroxide is added according to the bile amount of 50g / L, that is, 5kg of sodium hydroxide is added, heated and boiled for 24 hours for saponification, and then calcium chloride with 5% of the bile weight is added, i.e. 5kg Calcium chloride, the total cholic acid calcium salt was precipitated, and the filtrate was discarded by centrifugation to obtain the total cholic acid calcium salt. The total cholic acid calcium salt is washed with 40kg of water, the water-insoluble matter is discarded, the pH of the aqueous solution is adjusted to 2 with 17-20% hydrochloric acid, and the crude chenodeoxycholic acid is precipitated, filtered, and dried to obtain the crude chenodeoxycholic acid .

Embodiment 3

[0032] Example 3 Separation and Purification of Chenodeoxycholic Acid

[0033] 1) Dissolution and extraction: Weigh 100g of the crude product of duck gall paste obtained in Example 1, add 500g of chloroform, 500g of methanol, and 500g of water, heat and reflux for 1 hour, after it is completely dissolved, cool to 25°C, and let it stand for stratification. Obtain the chloroform phase and the methanol / water phase, evaporate and recover the methanol, adjust the pH of the remaining water phase to 2 with hydrochloric acid with a mass percentage of 17-20%, crystallize, and centrifuge to obtain chenodeoxycholic acid product A;

[0034] 2) Ethyl acetate extraction: Dissolve chenodeoxycholic acid product A in 5% sodium hydroxide solution with 5 times the mass, cool to 20°C, add ethyl acetate in an amount of chenodeoxycholic acid product A per gram Add 5ml, adjust the pH to 7.2, separate layers to obtain ethyl acetate phase, continue to add ethyl acetate to the water layer, the amount a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com