Method for closed cycle high-efficiency comprehensive recovery of multiple elements of gold concentrate

A multi-element, gold concentrate technology, applied in the direction of non-metallic elements, chemical instruments and methods, sulfur compounds, etc., can solve problems such as poor economic benefits, difficult production, desulfurization by roasting, incomplete decarbonization, etc. Achieve the effect of improving economic efficiency, realizing zero discharge and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

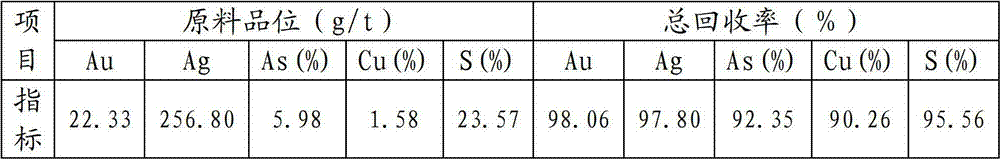

Embodiment 1

[0027] 1) Slurry mixing: In the slurry mixing tank, the sulfur-containing gold concentrate is mixed with sulfide ores of different components. The fineness of the gold concentrate is required to be 200 mesh, and the sulfur-containing mass fraction is 20-30%, and the arsenic-containing mass fraction is obtained. 5-8% sulfur-containing gold concentrate containing 1.5-3.5% copper by mass, adding water to adjust the sulfur-containing gold concentrate to a slurry containing 63% of the total mass fraction of solute;

[0028] 2) Two-stage roasting: The ore pulp is transported to the first-stage roasting device for one-stage roasting. The amount of oxygen used during roasting is 80-90% of the theoretical oxygen required for the oxidation of sulfur, arsenic, carbon and other chemical elements in the mineral to form oxides. , the roasting temperature is 550°C, and roasted for 20 minutes; the calcined sand obtained after the first-stage roasting enters the second-stage roasting device for...

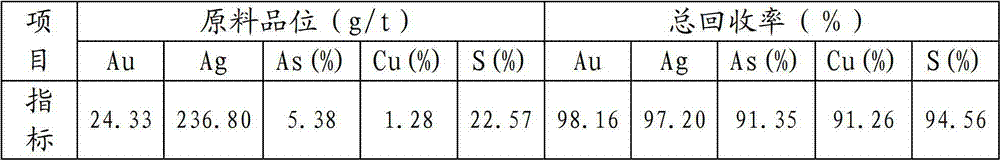

Embodiment 2

[0039] 1) Slurry mixing: In the slurry mixing tank, the sulfur-containing gold concentrate is mixed with sulfide ores of different components. The fineness of the gold concentrate is required to be 300 mesh, and the sulfur-containing mass fraction is 20-30%, and the arsenic-containing mass fraction is obtained. 5-8% sulfur-containing gold concentrate containing 1.5-3.5% copper by mass, adding water to adjust the sulfur-containing gold concentrate to a slurry containing 65% of the total mass fraction of solute;

[0040] 2) Two-stage roasting: The ore pulp is transported to the first-stage roasting device for one-stage roasting. The amount of oxygen used during roasting is 80-90% of the theoretical oxygen required for the oxidation of sulfur, arsenic, carbon and other chemical elements in the mineral to form oxides. , the roasting temperature is 570°C, and roasted for 20 minutes; the calcined sand obtained after the first-stage roasting enters the second-stage roasting device for...

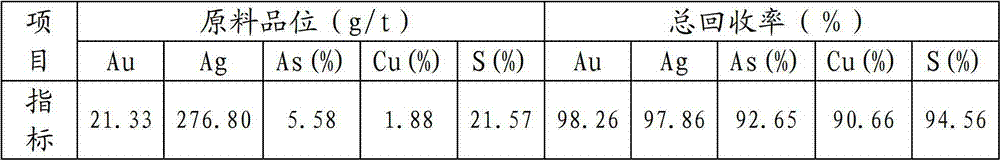

Embodiment 3

[0051] 1) Slurry mixing: In the slurry mixing tank, the sulfur-containing gold concentrate is mixed with sulfide ores of different components. The fineness of the gold concentrate is required to be 400 mesh, and the sulfur-containing mass fraction is 20-30%, and the arsenic-containing mass fraction is obtained. 5-8% sulfur-containing gold concentrate containing 1.5-3.5% copper by mass, adding water to adjust the sulfur-containing gold concentrate into a slurry containing 70% of the total mass fraction of solute;

[0052] 2) Two-stage roasting: The ore pulp is transported to the first-stage roasting device for one-stage roasting. The amount of oxygen used during roasting is 80-90% of the theoretical oxygen required for the oxidation of sulfur, arsenic, carbon and other chemical elements in the mineral to form oxides. , the roasting temperature is 600°C, and roasted for 20 minutes; the calcined sand obtained after the first-stage roasting enters the second-stage roasting device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com