Lost foam coating and preparation method thereof

A technology of lost foam and coating, which is applied in the direction of coating, manufacturing tools, casting and molding equipment, etc. It can solve the problems of increasing the cost of grinding wheel grinding and the coating is not easy to peel off, achieving the best peeling effect, saving labor, and excellent air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

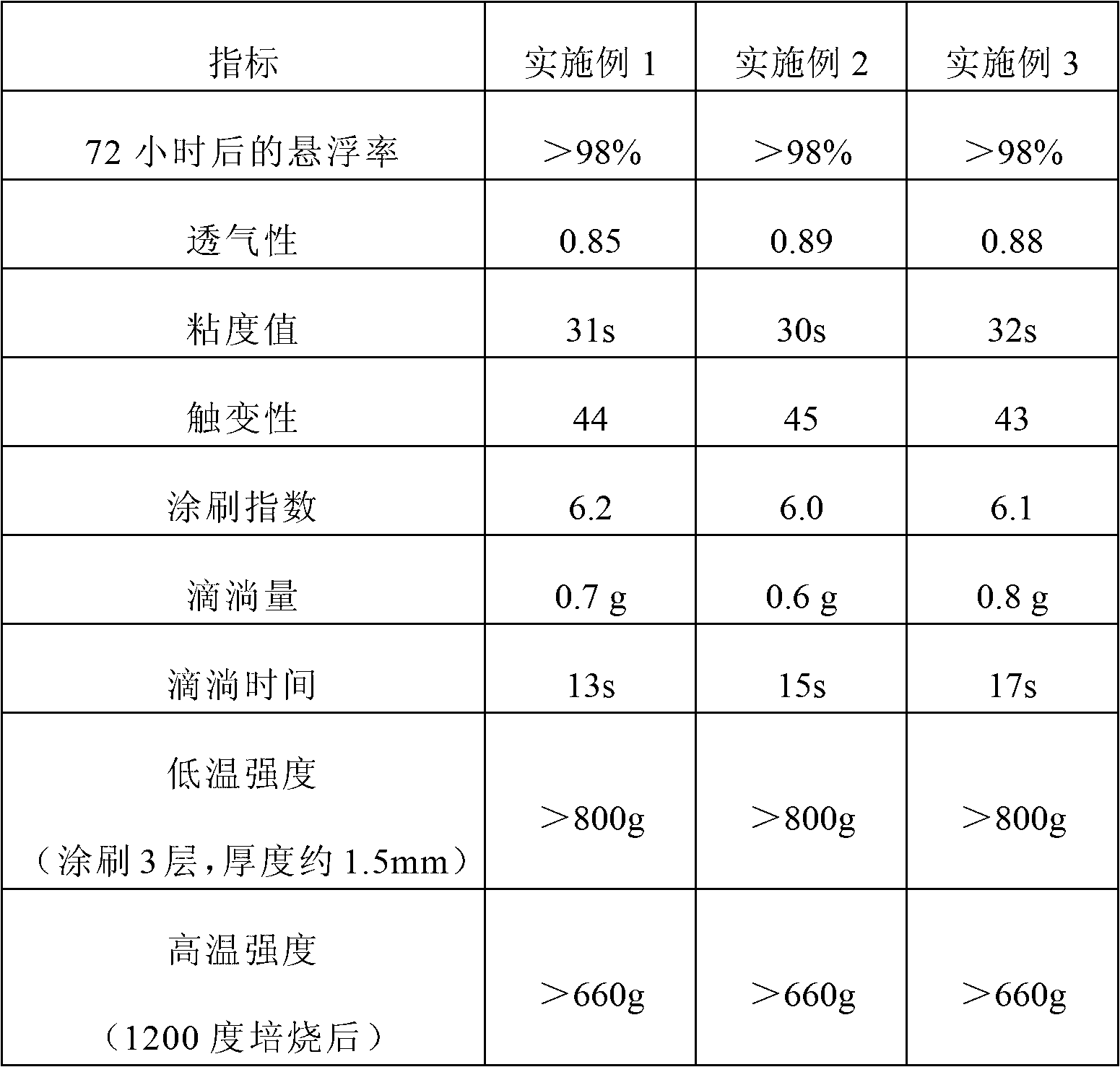

Examples

Embodiment 1

[0022] The ratio of each component of the lost foam coating is: 30 parts by weight of high alumina bauxite clinker, 25 parts by weight of magnesium oxide powder, 1 part by weight of sodium bentonite, 1.5 parts by weight of CMC, 0.5 parts by weight of polyvinyl alcohol, 0.3 parts by weight Parts of phenolic resin, 0.2 parts by weight of n-octanol, 0.5 parts by weight of iron oxide red powder.

[0023] Follow the steps below to prepare lost foam coatings:

[0024] First, mix 1 part by weight of sodium bentonite with 18 parts by weight of water, and stir at a high speed of 1000 rpm or more for 5 hours to form a bentonite slurry; meanwhile, take 30 parts by weight of high alumina bauxite clinker and 25 parts by weight of magnesium oxide powder in the grinding equipment Stir evenly in the medium, add 28 parts by weight of water therein, and stir to make it form aggregate. Then get 1.5 parts by weight of CMC, 0.5 parts by weight of polyvinyl alcohol, 0.3 parts by weight of phenolic...

Embodiment 2

[0028] The ratio of each component of the lost foam coating is: 35 parts by weight of high alumina bauxite clinker, 20 parts by weight of magnesium oxide powder, 2 parts by weight of sodium bentonite, 1 part by weight of CMC, 1 part by weight of polyvinyl alcohol, 0.5 parts by weight Parts of phenolic resin, 0.3 parts by weight of n-octanol, 1 part by weight of iron oxide red powder.

[0029] Follow the steps below to prepare lost foam coatings:

[0030] First, mix 2 parts by weight of sodium bentonite with 20 parts by weight of water, and stir at a high speed above 1000rpm for 6 hours to form a bentonite slurry; meanwhile, take 35 parts by weight of high alumina bauxite clinker and 20 parts by weight of magnesium oxide powder in the grinding equipment Stir evenly in the medium, add 30 parts by weight of water therein, and stir to make it form aggregate. Then get 1 weight part CMC, 1 weight part polyvinyl alcohol, 0.5 weight part phenolic resin, 0.3 weight part n-octanol, 1 w...

Embodiment 3

[0034] The ratio of each component of the lost foam coating is: 40 parts by weight of high alumina bauxite clinker, 15 parts by weight of magnesium oxide powder, 3 parts by weight of sodium bentonite, 0.5 parts by weight of CMC, 1.5 parts by weight of polyvinyl alcohol, 0.8 parts by weight Parts of phenolic resin, 0.4 parts by weight of n-octanol, 1.5 parts by weight of iron oxide red powder.

[0035] Follow the steps below to prepare lost foam coatings:

[0036] First, mix 3 parts by weight of sodium bentonite with 22 parts by weight of water, and stir at a high speed above 1000rpm for 7 hours to form bentonite slurry; meanwhile, take 40 parts by weight of high alumina bauxite clinker and 15 parts by weight of magnesium oxide powder in the grinding equipment Stir evenly in the medium, add 32 parts by weight of water therein, and stir to make it form aggregate. Then get 0.5 parts by weight of CMC, 1.5 parts by weight of polyvinyl alcohol, 0.8 parts by weight of phenolic resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com