Preparation method of polyhedral copper nanoparticle

A technology of copper nanoparticles and nanoparticles, which is applied in the field of nanomaterials, can solve the problem of poor catalytic performance of polyhedral copper nanoparticles, and achieve the effects of excellent catalytic performance, good sample crystallinity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

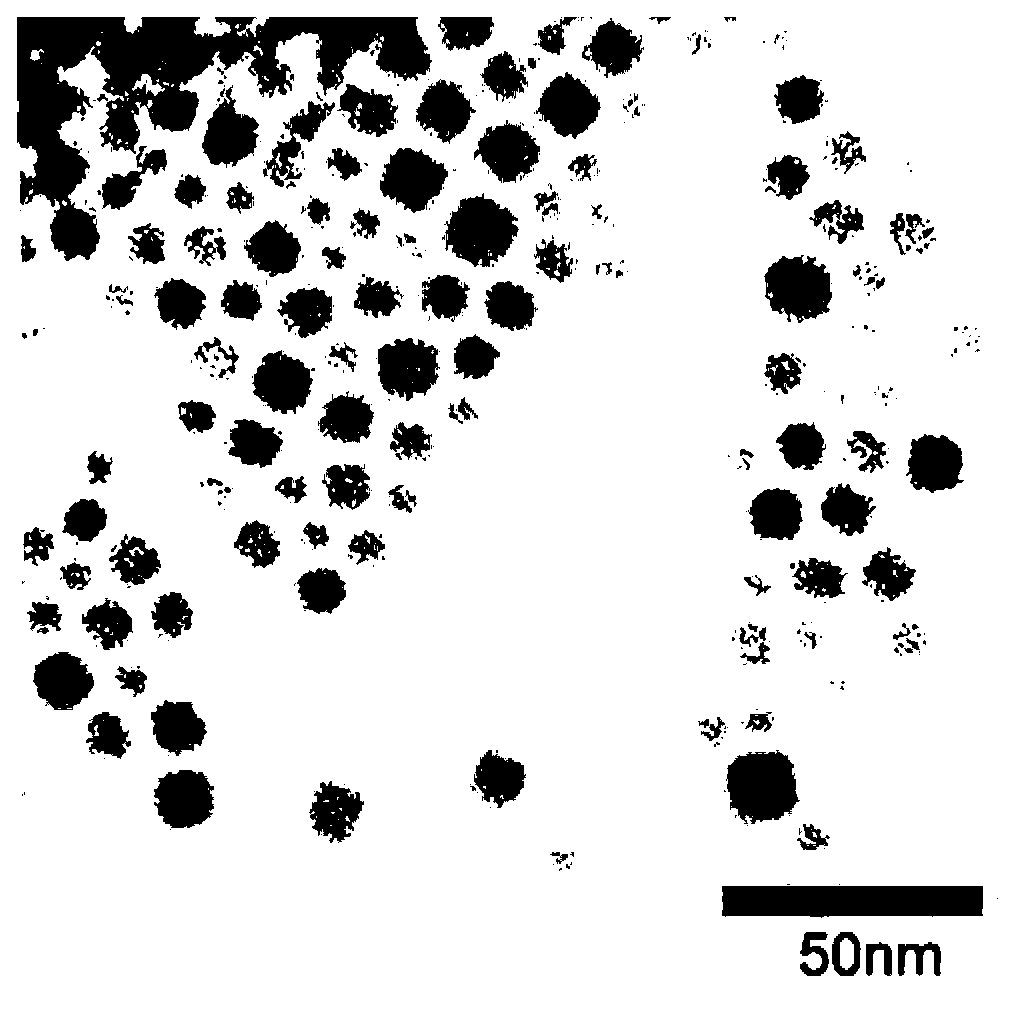

[0032] Put 0.0016g of copper oxide powder, 3mL of oleic acid and 3mL of octadecene into a 50mL three-necked flask of the Schlenk system, then plug the two sides of the three-necked flask with rubber stoppers, and connect the middle port to the condenser with condensation. The air vent is filled with nitrogen, and the air in the three-necked bottle is replaced, so that the three-necked bottle is filled with nitrogen, and then the thermocouple is inserted into the liquid surface from the side port of the three-necked bottle, heated and stirred, and the temperature is raised to A clear solution was formed at 245±5°C. Subsequently, 3 mL of oleylamine was added, and the mixed solution turned into brown-red turbidity to form copper nanoparticles, which was the starting point for the growth of copper nanoparticles. After the reaction time was 5 minutes, the sample was extracted and cooled to room temperature naturally, and the sample was washed twice with a mixed solution of methanol...

Embodiment 2

[0035] On the basis of the reaction time of 5 minutes in Example 1, after 10 minutes, that is, the reaction time is 15 minutes, the sample is extracted again and cooled to room temperature, and the sample is washed twice with a mixed solution of methanol and acetone in a volume ratio of 1:1. The copper nano-single crystal particles are obtained.

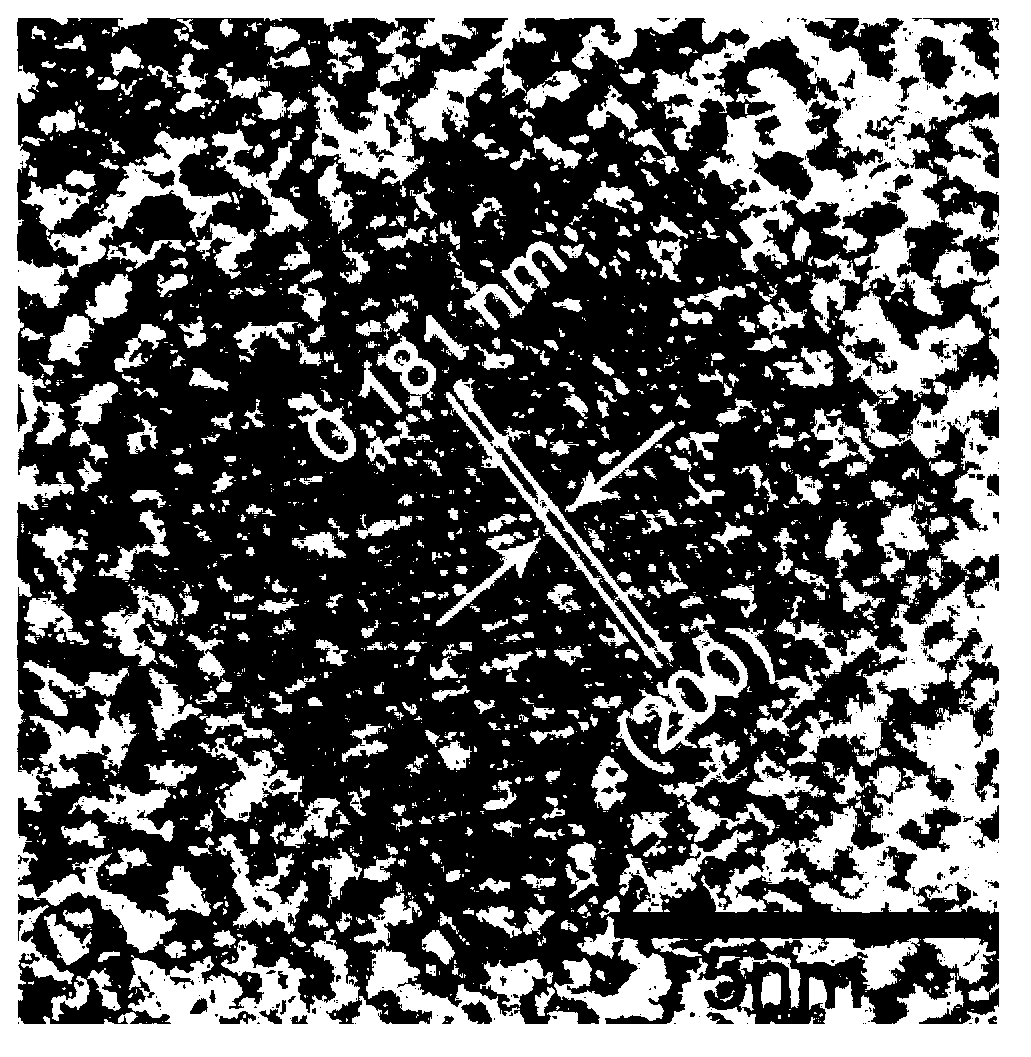

[0036] Samples grown for 15 minutes were characterized. image 3 is the TEM image of the polyhedral copper nanoparticles obtained when the growth time is 15 minutes, and the average particle size of the copper nanoparticles is 18.0 nanometers. Figure 4is a high-resolution electron microscope image of a single polyhedral copper nanoparticle.

Embodiment 3

[0038] On the basis of the reaction time of Example 2 of 15 minutes, another 25 minutes passed, that is, the reaction time was 40 minutes, and the sample was extracted for the third time and cooled to room temperature naturally, and the sample was washed 2 times with methanol and acetone mixed solution with a volume ratio of 1:1. Copper nano single crystal particles can also be obtained.

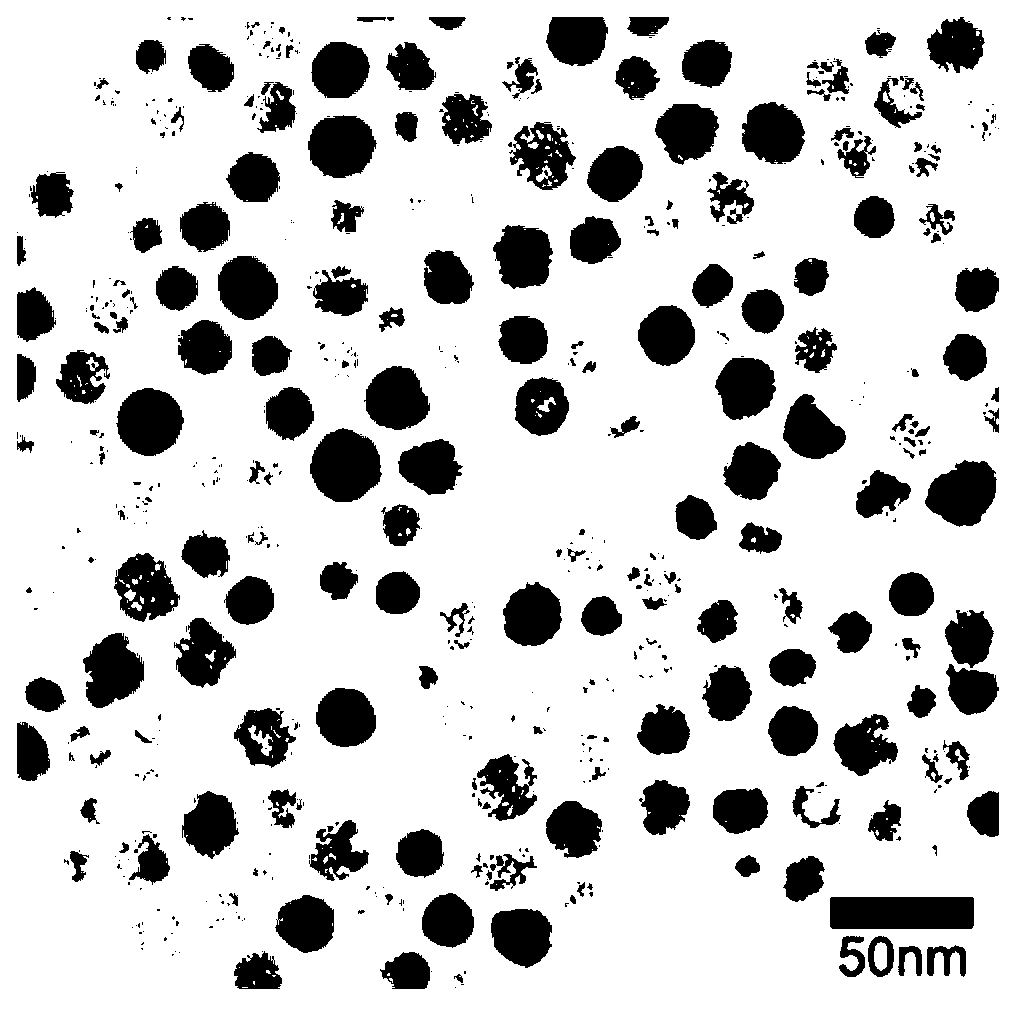

[0039] Samples with a growth time of 40 minutes were characterized. Figure 5 It is a transmission electron microscope image of polyhedral copper nanoparticles obtained when the growth time is 40 minutes, and the average particle diameter of copper nanoparticles is 21.5 nanometers after statistics. Image 6 is a high-resolution electron microscope image of a single polyhedral copper nanoparticle. The X-ray diffraction pattern of polyhedral copper nanoparticles is shown in Figure 7 As shown, it is a face-centered cubic structure and has good crystallinity, completely corresponding to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com