Method for preparing fluorine-containing olefin by selective dehydrohalogenation with halogenated hydrocarbon

A technology for dehydrohalogenation and fluorine-containing olefins, which is applied in the fields of dehydrohalogenation preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. There are many by-products in the process, and the effect of high dehydrohalogenation selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] 1. Preparation of composite catalyst

[0024] The composite catalyst is prepared by the co-precipitation-impregnation method. The sulfate, nitrate or chloride salt of alkaline earth metal is dissolved in water, and then the precipitant ammonia water, sodium hydroxide or sodium carbonate aqueous solution is added dropwise to the above solution, and the slurry is filtered out After drying, the doping ion solution is impregnated in the catalyst matrix, and then dried and calcined to obtain a composite catalyst for dehydrohalogenation.

[0025] For example: 11.0g magnesium chloride (MgCl 2 ), 24.0g barium nitrate (Ba(NO 3 ) 2 ) was dissolved in 200ml distilled water to make a solution, and then 5mol / l sodium carbonate (Na 2 CO 3 ) aqueous solution was added dropwise to the above solution to pH = 11, the slurry was filtered out, dried overnight at 150°C, and then the solid was immersed in 50ml of KCl aqueous solution for 5 hours, and evaporated to dryness on a rotary eva...

Embodiment 1

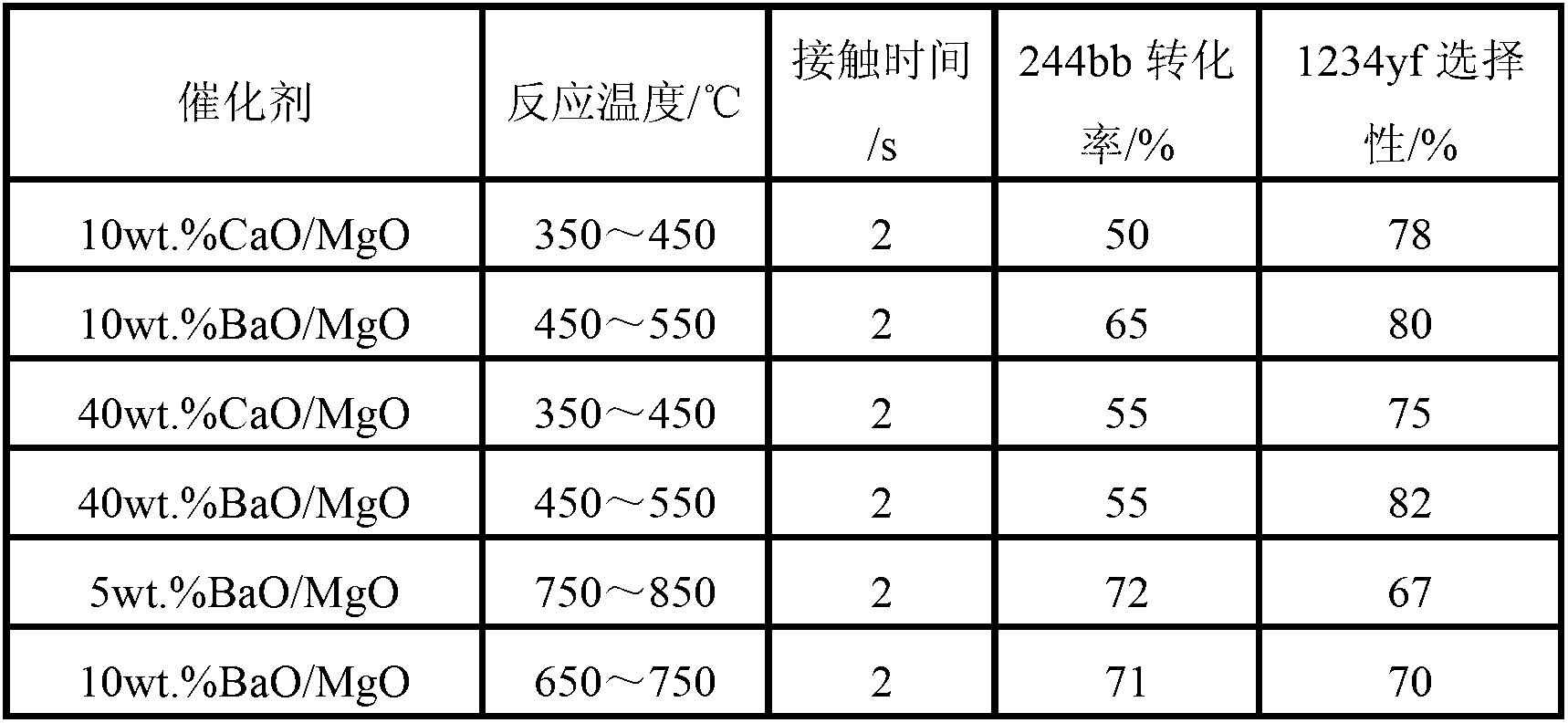

[0027] A series of composite alkaline earth metal oxides were used as dehydrohalogenation catalysts. In a typical test, 60ml of composite catalyst (BaO / MgO) is loaded into a fixed-bed tubular reactor with a diameter of Φ38mm, and at a reaction temperature ranging from 200°C to 850°C, 90wt.% of 2- A mixture of chloro-1,1,1,2-tetrafluoropropane (HCFC-244bb), 5wt.% of 2-chloro-3,3,3-trifluoropropene and 5wt.% of HF was passed through the catalyst bed. The reaction product was washed with water and alkali to remove HCl and HF, and then analyzed by gas chromatography. The analysis method was the area normalization method. The reaction results are shown in Table 1.

[0028] Table 1

[0029]

Embodiment 2

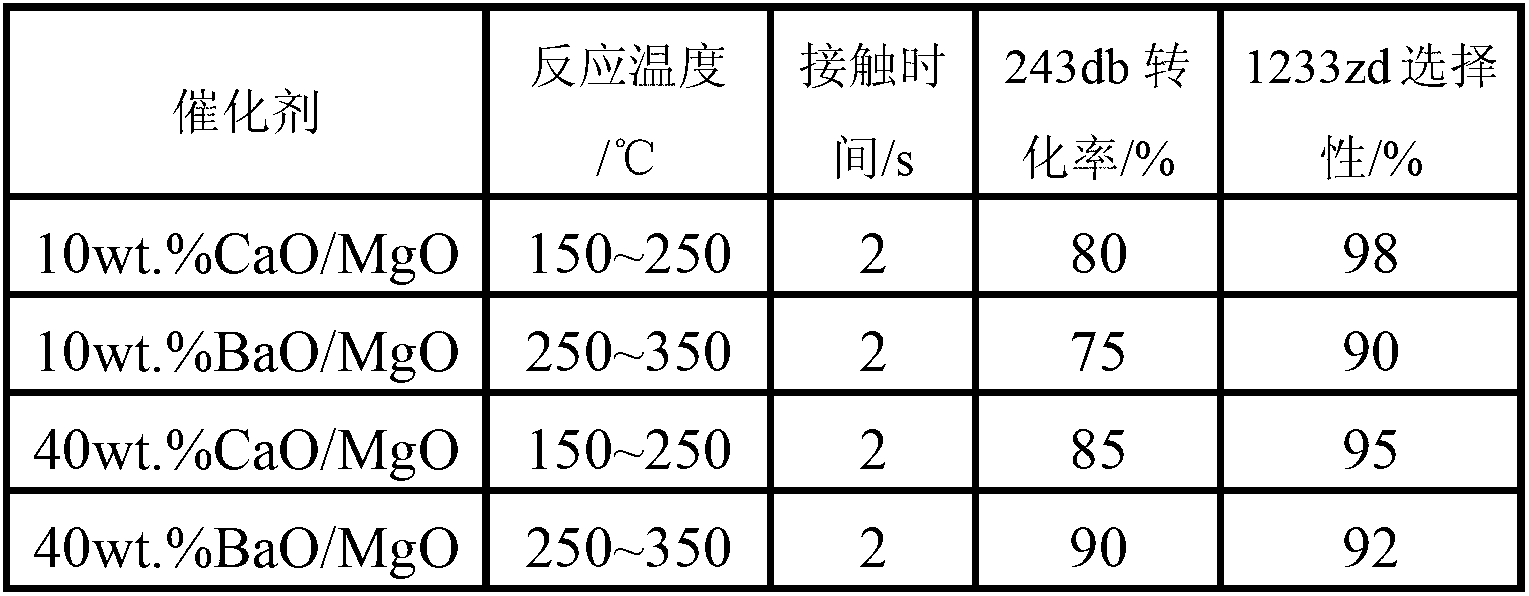

[0031] The same operating conditions as in Example 1, the difference is that the reaction raw material 2-chloro-1,1,1,2-tetrafluoropropane is replaced by 2,3-dichloro-1,1,1-trifluoropropane ( HCFC-243db), the reaction results are shown in Table 2.

[0032] Table 2

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com