Organic fluorine oxosilane nanometer freezing sticky resistant coating and preparation process thereof

A fluorosiloxane, anti-freeze stick technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of incomplete cleaning, reduce freeze stick strength, accelerate electrical energy loss, etc., to reduce solid surface energy, overcome stickiness, etc. Low junction strength, effect of reducing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

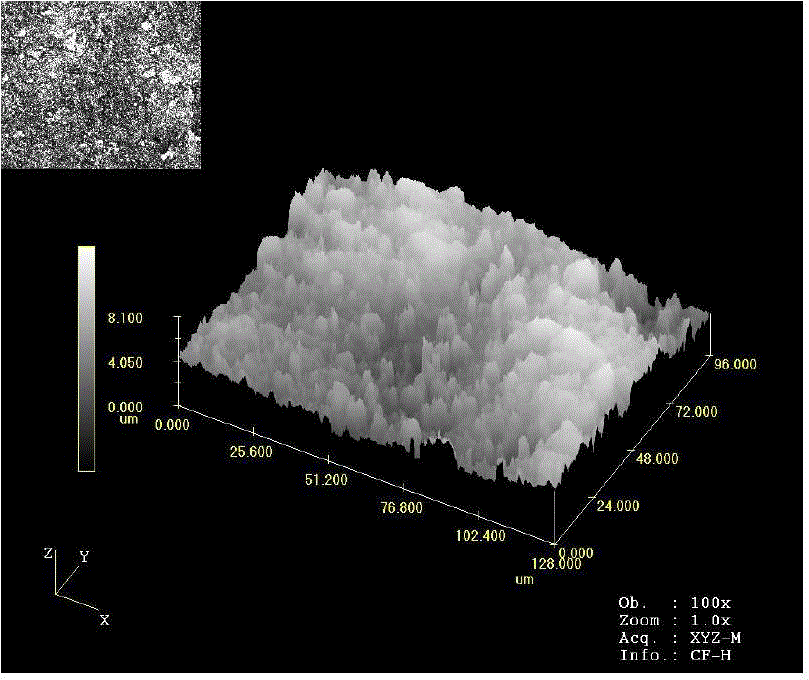

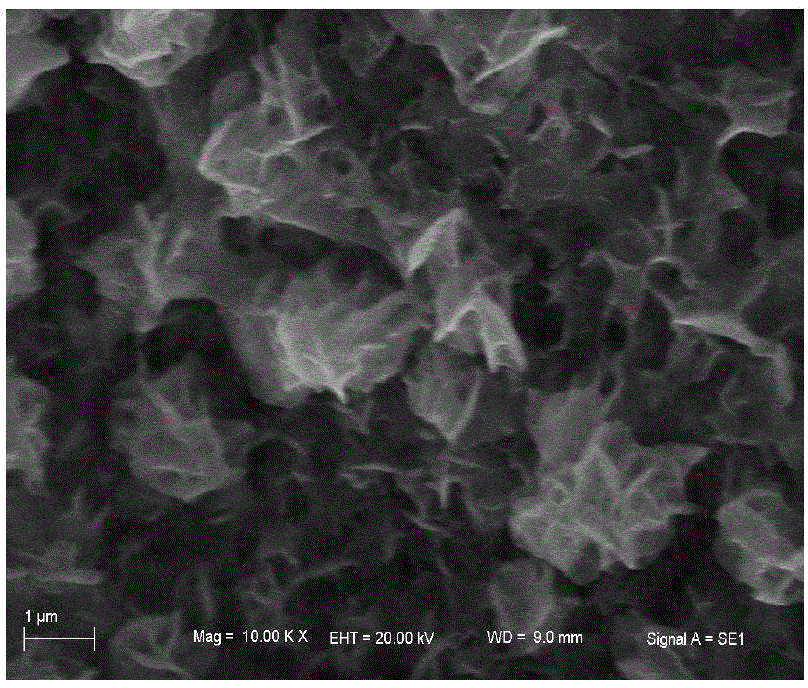

Method used

Image

Examples

Embodiment 1

[0043] First, make tridecafluorooctyltriethoxysilane into a certain amount of ethanol and deionized water solution (volume ratio: 1:97:2), hydrolyze at room temperature for at least 48 hours, and then take 15 % heptadecafluorodecyltriethoxysilane solution and 35% polyvinyl butyral, add it to 30% diluent acetone, and then add 5% of the total amount of paint to the above solution Plasticizer dioctyl phthalate and 2% nano silicon dioxide, then add 1% stannous octoate, 1% dispersant AMJ Dispers H-942, 1% defoamer AMJ Defoam 8057, and finally in React at 90°C for 2-4 hours, ball mill for 60 hours, add 10% combined isocyanate (T-M-H), stir evenly, apply on the surface of the workpiece, and cure at room temperature for 6 hours.

Embodiment 2

[0045] First, heptadecafluorodecyltriethoxysilane was made into a certain amount of ethanol and deionized water solution (volume ratio: 1:97:2), hydrolyzed at room temperature for at least 48 hours, and then 18 % heptadecafluorodecyltriethoxysilane solution and 30% polyvinyl butyral, add it to 25% diluent acetone, and then add 3% of the total amount of paint to the above solution Plasticizer dioctyl phthalate and 2% nano silicon dioxide, then add 1% stannous octoate, 5% dispersant AMJ Dispers H-24000, 1% defoamer AMJ Defoam 8057, and finally in React at 90°C for 2-4 hours, ball mill for 80 hours, add 15% combined isocyanate (T-M-H), stir evenly, apply on the surface of the workpiece, and cure at room temperature for 5 hours.

Embodiment 3

[0047] First, heptadecafluorodecyltriethoxysilane was made into a certain amount of ethanol and deionized water solution (volume ratio: 1:97:2), hydrolyzed at room temperature for at least 48 hours, and then 20% of the total amount of the coating was taken. % heptadecafluorodecyltriethoxysilane solution and 33% polyvinyl butyral, add it to 20% diluent acetone, and then add 3% of the total amount of paint to the above solution Plasticizer dioctyl phthalate and 2% nano silicon dioxide, then add 0.5% stannous octoate, 6% dispersant AMJ Dispers H-24000, 0.5% defoamer AMJ Defoam 8057, and finally in React at 90°C for 2-4 hours, ball mill for 90 hours, add 15% combined isocyanate (T-M-H), stir evenly, apply on the surface of the workpiece, and cure at room temperature for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com