Preparation method for low excursion flat belt voltage silicon carbide (SiC) metal oxide semiconductor (MOS) capacitance

A technology of flat-band voltage and manufacturing method, which is applied in the field of microelectronics, can solve problems such as difficult nitrogen-containing gas dosage, influence on device interface characteristics, flat-band voltage offset, etc., and achieve reduction of dangling bonds, ease of interface stress, and flat-band voltage The effect of small offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

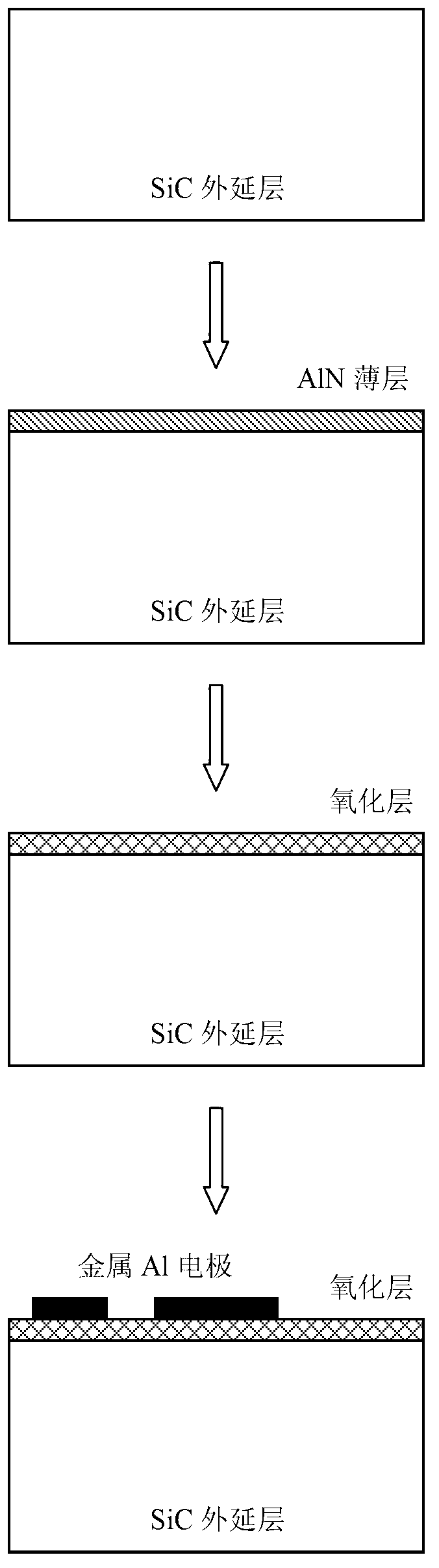

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, comprises the steps:

[0020] Step 1, perform standard cleaning treatment on the N-SiC epitaxial material:

[0021] 1.1) Ultrasonic cleaning of N-SiC epitaxial materials with deionized water;

[0022] 1.2) Clean with concentrated sulfuric acid, heat to smoke, cook for 10 minutes, soak for 30 minutes, and rinse the surface with deionized water several times;

[0023] 1.3) Use H in a ratio of 5:1:1 2 O, H 2 o 2 Soak the N-SiC epitaxial material washed with deionized water in a water bath for 5 minutes in the No. 1 mixed liquid composed of ammonia water at a temperature of 80°C, then wash it with hydrogen fluoride solution, and rinse the surface several times with deionized water for the second time ;

[0024] 1.4) Use H with a ratio of 6:1:1 2 O, H 2 o 2 In the No. 2 mixed liquid composed of HCl at a temperature of 80°C, soak the N-SiC epitaxial material after the second rinse with deionized water in a water bath for 5 minutes, wash it with hydrogen ...

Embodiment 2

[0029] Embodiment 2, comprises the steps:

[0030] Step 1, perform standard cleaning treatment on the N-SiC epitaxial material:

[0031] 1.1) Ultrasonic cleaning of N-SiC epitaxial materials with deionized water;

[0032] 1.2) Clean with concentrated sulfuric acid, heat to smoke, cook for 10 minutes, soak for 30 minutes, and rinse the surface with deionized water several times;

[0033] 1.3) Use H in a ratio of 5:1:1 2 O, H 2 o 2 Soak the N-SiC epitaxial material washed with deionized water in a water bath for 5 minutes in the No. 1 mixed liquid composed of ammonia water at a temperature of 80°C, then wash it with hydrogen fluoride solution, and rinse the surface several times with deionized water for the second time ;

[0034] 1.4) Use H with a ratio of 6:1:1 2 O, H 2 o 2 In the No. 2 mixed liquid composed of HCl at a temperature of 80°C, soak the N-SiC epitaxial material after the second rinse with deionized water in a water bath for 5 minutes, wash it with hydrogen ...

Embodiment 3

[0039] Embodiment 3, comprises the steps:

[0040] Step 1, perform standard cleaning treatment on the N-SiC epitaxial material:

[0041] 1.1) Ultrasonic cleaning of N-SiC epitaxial materials with deionized water;

[0042] 1.2) Clean with concentrated sulfuric acid, heat to smoke, cook for 10 minutes, soak for 30 minutes, and rinse the surface with deionized water several times;

[0043] 1.3) Use H in a ratio of 5:1:1 2 O, H 2 o 2Soak the N-SiC epitaxial material washed with deionized water in a water bath for 5 minutes in the No. 1 mixed liquid composed of ammonia water at a temperature of 80°C, then wash it with hydrogen fluoride solution, and rinse the surface several times with deionized water for the second time ;

[0044] 1.4) Use H with a ratio of 6:1:1 2 O, H 2 o 2 In the No. 2 mixed liquid composed of HCl at a temperature of 80°C, soak the N-SiC epitaxial material after the second rinse with deionized water in a water bath for 5 minutes, wash it with hydrogen f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com