Special flavor pork skin paste and production method thereof

A production method and technology of pork skin sauce, applied in the fields of application, food preparation, food science, etc., can solve the problem that pork skin can only be used for solid food and chemical raw materials, achieve good spreadability and ductility, improve flavor, and produce The effect of mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

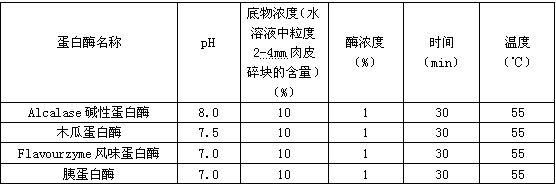

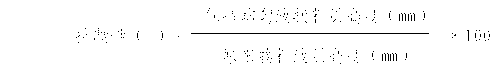

Method used

Image

Examples

Embodiment 1

[0035] Example 1: spicy pork skin sauce

[0036] (1) Product formula, consisting of the following raw materials in parts by weight:

[0037] 40 parts of pure soybean paste, 20 parts of pork skin, 18 parts of soybean oil, 12 parts of dried red pepper flakes, 3 parts of cooked peanut powder, 0.5 parts of pepper powder, 0.3 parts of aniseed powder, 4 parts of peppercorns, 3 parts of table salt, onion 4 parts, MSG 1.5 parts, water 25 parts;

[0038] (2) Refreshing treatment of dried red pepper flakes

[0039] Pepper flakes with a particle size of 2-3 mm and intact seeds are scalded with 2.5 times the mass of boiling water, sealed, and placed at room temperature for 6 hours for refreshment treatment, and set aside.

[0040] (3) Peanut processing

[0041] Choose fresh "four grains of red" peanuts with no mildew, no moths, and full grains, rinse them with running water, drain the water, bake at 150°C for 20 minutes, raise the temperature to 180°C, and continue to bake for 20 minut...

Embodiment 2

[0056] Example 2: Spicy pork skin sauce

[0057] (1) Product formula, consisting of the following raw materials in parts by weight:

[0058] 25 parts of pure soybean paste, 12.5 parts of pork skin, 14 parts of soybean oil, 7.5 parts of dried red pepper flakes, 2 parts of cooked peanut powder, 0.3 parts of pepper powder, 0.2 parts of aniseed powder, 0.25 parts of peppercorns, 2 parts of table salt, onion 2.5 parts, 1.0 parts MSG, 15 parts water;

[0059] (2) Refreshing treatment of dried red pepper flakes

[0060] Pepper flakes with a particle size of 2-3 mm and intact seeds are scalded with 2.2 times the mass of boiling water, sealed, placed at room temperature for 5 hours, and re-fresh, and set aside;

[0061] (3) Peanut processing

[0062] Choose fresh "four grains of red" peanuts with no mildew, no moths, and full grains, rinse them with running water, drain the water, bake at 150°C for 20 minutes, raise the temperature to 180°C, and continue to bake for 20 minutes until...

Embodiment 3

[0077] Example 3: slightly spicy pork skin sauce

[0078] (1) Product formula, consisting of the following raw materials in parts by weight:

[0079] 10 parts of noodle sauce, 5 parts of pork skin, 10 parts of corn germ oil, 3 parts of dried red pepper flakes, 1 part of cooked peanut powder, 0.1 part of pepper powder, 0.1 part of aniseed powder, 0.1 part of peppercorns, 1 part of table salt, onion 1 part, 0.5 parts of monosodium glutamate, 5 parts of water;

[0080] (2) Refreshing treatment of dried red pepper flakes

[0081] Pepper flakes with a particle size of 2-3mm and complete seeds are scalded with boiling water twice the mass, sealed, and placed at room temperature for 4 hours for refreshment treatment, and set aside;

[0082] (3) Peanut processing

[0083] Choose fresh "four grains of red" peanuts with no mildew, no moths, and full grains, rinse them with running water, drain the water, bake at 150°C for 20 minutes, raise the temperature to 180°C, and continue to ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com