Filling material for sandwiched building plate

A filling material and atrium technology, applied in the field of building materials, can solve problems such as poor thermal insulation performance and sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

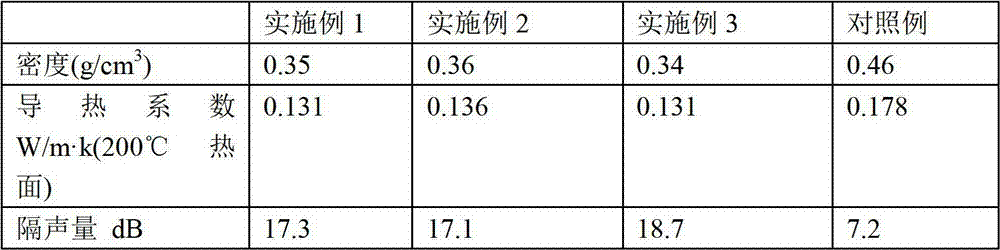

Examples

Embodiment Construction

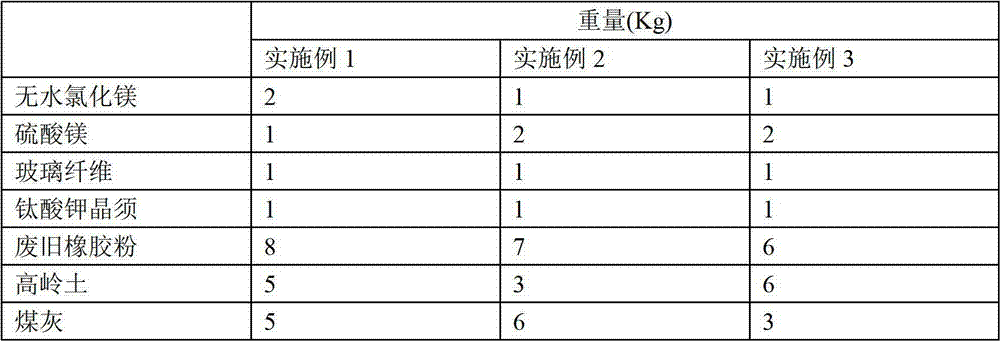

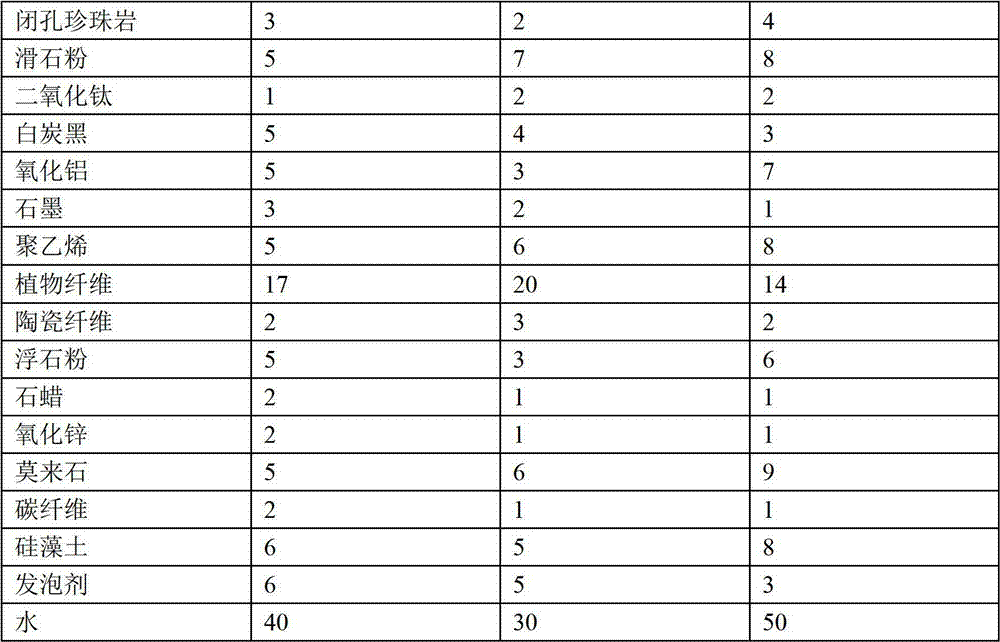

[0019] Take each component by weight ratio in Table 1

[0020] The weight proportion of table 1 embodiment 1~embodiment 3

[0021]

[0022]

[0023] The above-mentioned waste rubber powder particle diameter is 2~3mm.

[0024] The above-mentioned waste rubber powder is made of styrene-butadiene rubber.

[0025] The foaming agent is azodicarbonamide.

[0026] The plant fiber is a mixture of corn stalks, hemp fibers, paper chips or wood chips in any proportion.

[0027] The diameter of the plant fiber is 0.5-3mm, and the length is 1-10mm. Its preparation method is:

[0028] S1: Mix anhydrous magnesium chloride, magnesium sulfate, glass fiber, potassium titanate whiskers and half of the water, and stir evenly;

[0029] S2: Add waste rubber powder, kaolin, coal ash, closed-cell perlite, talcum powder, titanium dioxide, white carbon black, alumina, graphite, polyethylene, plant fiber, ceramic fiber, pumice powder, paraffin, to the mixture obtained in S1. Zinc oxide, mull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com