Nitrogen organic modified titanium-containing blast furnace slag catalyst with visible light catalytic activity and preparation method thereof

A catalytic activity, blast furnace slag technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high investment in degradation equipment and degradation operation costs, waste of titanium resources, and low application value. , to achieve the effect of improving visible light catalytic activity, good social and economic benefits, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

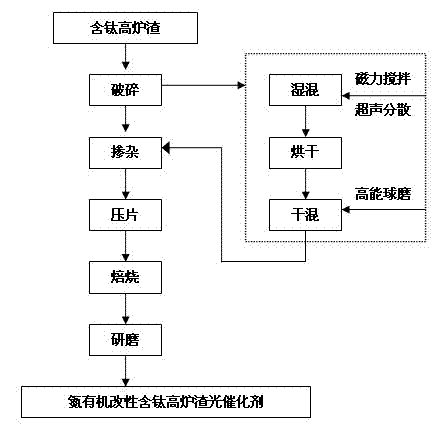

Method used

Image

Examples

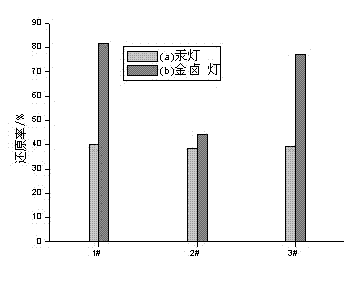

Embodiment 1

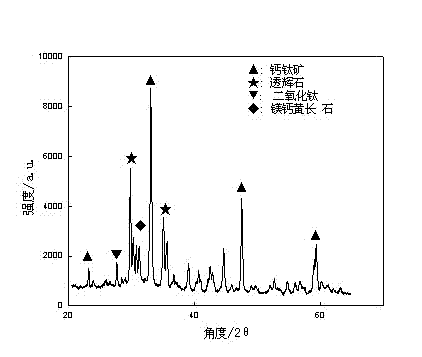

[0036] Visible light catalytically active nitrogen organically modified titanium-containing blast furnace slag catalyst, the chemical composition is based on mass percentage, nitrogen element 7.5wt%, the balance is titanium-containing blast furnace slag components and impurities, and the mass ratio of nitrogen to titanium of the catalyst is 0.3:1.

[0037] After crushing the titanium-containing blast furnace slag, the titanium-containing blast furnace slag powder with a diameter of less than 1 mm is obtained through screening;

[0038] Mix and grind industrial urea with crushed titanium-containing blast furnace slag powder. The mixing ratio is based on the mass of nitrogen in urea accounting for 7.5wt% of the mass of the mixed powder, wherein the mass ratio of nitrogen and titanium is 0.3:1, and the titanium-containing blast furnace slag contains titanium dioxide. 25%;

[0039] Add absolute ethanol to the mixed powder, ultrasonically disperse for 50 minutes; transfer the conta...

Embodiment 2

[0051] Visible light catalytically active nitrogen organically modified titanium-containing blast furnace slag catalyst, the chemical composition is by mass percentage, nitrogen element 15wt%, the balance is titanium-containing blast furnace slag components and impurities, and the mass ratio of nitrogen to titanium of the catalyst is 7.5:1.

[0052] After crushing the titanium-containing blast furnace slag, the titanium-containing blast furnace slag powder with a diameter of less than 0.5mm is obtained through screening;

[0053] Mix and grind industrial urea with crushed titanium-containing blast furnace slag powder. The mixing ratio is based on the nitrogen element in urea accounting for 15wt% of the mixed powder mass, wherein the mass ratio of nitrogen and titanium is 7.5:1, and the titanium-containing blast furnace slag contains titanium dioxide 2 %;

[0054] Add absolute ethanol to the mixed powder, ultrasonically disperse for 10 minutes; transfer the container containing...

Embodiment 3

[0063] Visible light catalytically active nitrogen organically modified titanium-containing blast furnace slag catalyst, the chemical composition is based on mass percentage, nitrogen element 20wt%, the balance is titanium-containing blast furnace slag components and impurities, and the mass ratio of nitrogen to titanium in the catalyst is 10:1.

[0064] After crushing the titanium-containing blast furnace slag, the titanium-containing blast furnace slag powder with a diameter of less than 1 mm is obtained through screening;

[0065] Mix and grind industrial urea with crushed titanium-containing blast furnace slag powder. The mixing ratio is based on the nitrogen element in urea accounting for 20wt% of the mixed powder mass, wherein the mass ratio of nitrogen and titanium is 1.3:1, and the titanium-containing blast furnace slag contains titanium dioxide 16 %;

[0066] Add absolute ethanol to the mixed powder, ultrasonically disperse for 30 minutes; transfer the container conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com