Method for preparing nanometer ferroferric oxide through acid-regenerating desilicated mud cake

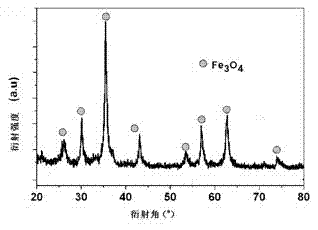

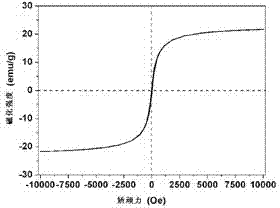

A technology of ferric tetroxide and desiliconized mud cake, which is applied in iron oxide/iron hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., to achieve uniform particle size dispersion, easy demagnetization, and easy charging. magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of method utilizing acid regeneration desiliconization mud cake to prepare nano iron ferric oxide, specifically comprises the following steps:

[0031] (1) Add 500mL of water to 200g of massive desiliconized mud cake, and make a slurry under the condition of heating at 80°C, and finally form a desiliconized slurry with good dispersibility;

[0032] (2) According to the mass volume ratio of desiliconized mud cake and regenerated acid, that is, the ratio of desiliconized mud cake: regenerated acid is 1g: 2ml, add regenerated acid to the desiliconized mud obtained in step (1), and continue After heating and stirring at 80°C for 2 hours, throw 100g of thin iron side material, heat to 80°C to achieve acid dissolution and reduction of the desiliconized mud cake, then filter, wash with water, adjust pH=4 with ammonia water, and set the volume to 1L to obtain iron turbid liquid;

[0033] (3) Take the ferrous chloride turbid solution obtained in step (2), add 600g of dod...

Embodiment 2

[0038] A kind of method utilizing acid regeneration desiliconization mud cake to prepare nano iron ferric oxide, specifically comprises the following steps:

[0039] (1) Add 400ml of water to 200g of massive desiliconized mud cake, and beat under the condition of heating at 80°C, and finally form desiliconized mud with better dispersibility;

[0040] (2) According to the mass volume ratio of desiliconized mud cake and regenerated acid, that is, the ratio of desiliconized mud cake: regenerated acid is 1g: 2ml, add regenerated acid to the desiliconized mud obtained in step (1), and continue for 80 After heating and stirring at ℃ for 2 hours, put in 200g of thin iron trim, heat to 85℃ to achieve acid dissolution and reduction of the desiliconized mud cake, then filter and wash with water, adjust the pH to 4 with ammonia water, and set the volume to 500ml to obtain chlorinated ferrous turbid liquid;

[0041] (3) Take the ferrous chloride turbid solution obtained in step (2), add ...

Embodiment 3

[0044] A kind of method utilizing acid regeneration desiliconization mud cake to prepare nano iron ferric oxide, specifically comprises the following steps:

[0045] (1) Add 400mL of water to 200g of massive desiliconized mud cake, and beat under the condition of heating at 80℃, and finally form desiliconized mud with good dispersibility;

[0046](2) According to the mass volume ratio of desiliconized mud cake and regenerated acid, that is, the ratio of desiliconized mud cake: regenerated acid is 1g: 2ml, add regenerated acid to the desiliconized mud obtained in the above (a) step, and continue After heating and stirring at 80°C for 2 hours, put in 160g of thin iron scrap, heat to 85°C to achieve acid dissolution and reduction of the desiliconized mud cake, then filter and wash with water. Adjust the pH=4 with ammonia water, and set the volume to 500ml to obtain the ferrous chloride turbid solution;

[0047] (3) Add 840 g of n-octadecylamine to the ferrous chloride turbid sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com