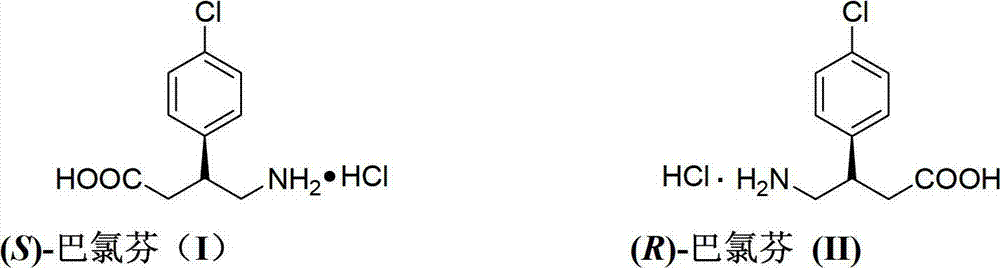

Preparation method of chiral baclofen

A baclofen and chiral technology, applied in the field of preparation of chiral baclofen (-baclofen, -baclofen), can solve the problems of expensive reagents, complicated operations, long reaction routes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

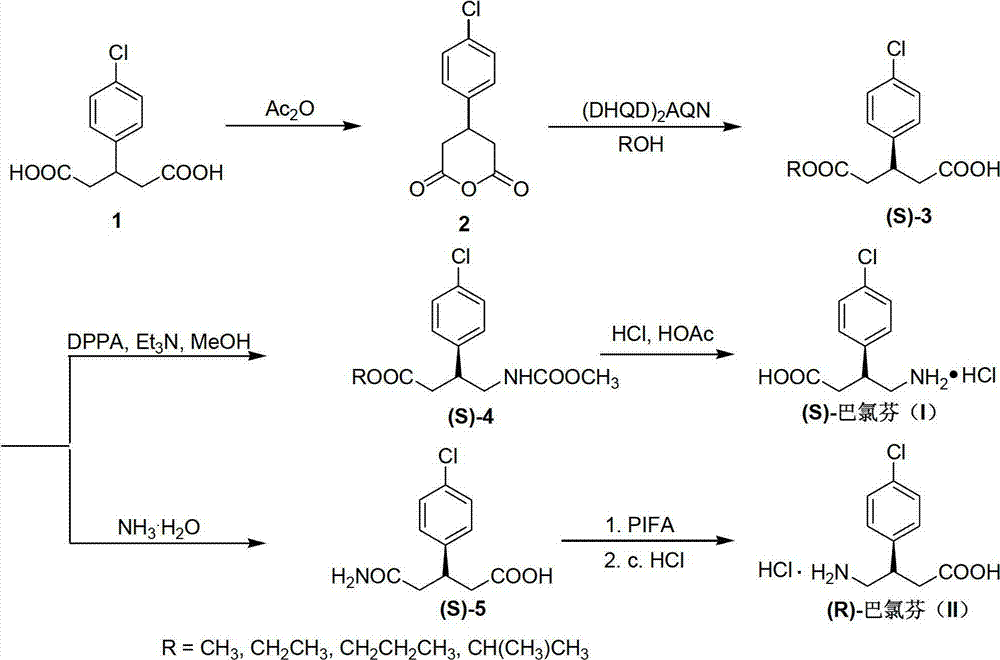

Method used

Image

Examples

Embodiment 1

[0027] Add 3-(4-chlorophenyl)glutaric acid (3.70g, 15.29mmol) into acetic anhydride (4.2mL, 45.87mmol), and reflux until completely dissolved. Cool to room temperature, add diethyl ether (3mL) dropwise, filter, wash with a little cold diethyl ether, and dry to obtain 2.77g of 3-(4-chlorophenyl)glutaric anhydride, yield: 81%, mp: 128-129°C . 1 H NMR (500MHz, CDCl 3 ):δ2.81–2.87(m,2H),3.07–3.11(m,2H),3.40–3.45(m,1H),7.16(d,J=9.0Hz,2H),7.37(d,J=9.0 Hz,2H); 13 C NMR (125MHz, CDCl 3 ):33.51,36.91(2C),127.63(2C),129.49(2C),133.97,137.52,165.55(2C);FT-IR(KBr,cm -1 ):1759(CO); MS(m / z,%rel intensity):226(M + , 37 Cl,6),224(M + , 35 Cl,15),140(33),138(100),115(9),103(26),77(9); HRMS(ESI) calcd for C 11 h 10 ClO 3 [M+H] + :225.0313,found:225.0316.

Embodiment 2

[0029] Under the protection of argon, add 3-(4-chlorophenyl)glutaric anhydride (0.32g, 1.43mmol) into 90mL of anhydrous ether, stir, cool, add (DHQD) 2 AQN (0.39g, 0.45mmol) was added dropwise to anhydrous methanol (0.46g, 14.30mmol) at a temperature of -40°C. After the addition was complete, the reaction was continued at a temperature of -40°C for 120h. Hydrochloric acid (1N, 42mL) was added, warmed to room temperature, extracted with ethyl acetate (3x 100mL), dried and concentrated. Column chromatography (cyclohexane / ethyl acetate=15:1, then ethyl acetate) gave (S)-3-(4-chlorophenyl)glutaric acid monomethyl ester 0.27g, yield: 75%, 95%ee, mp: 103-104°C; 1 H NMR (500MHz, CDCl 3 ):δ2.59–2.78(m,4H),3.58(s,3H),3.59–3.62(m,1H),7.16(d,J=8.5Hz,2H),7.27(d,J=8.5Hz, 2H); 13 C NMR (125MHz, CDCl 3 ):37.33,39.97,40.25,51.71,128.61(2C),128.82(2C),132.81,140.70,171.73,176.85; FT-IR(KBr,cm -1 ):3035,1729,1700,1435,1273,1222,1162; MS(m / z,%rel intensity):258(M + , 37 Cl,4),256(M + ...

Embodiment 3

[0031] At room temperature, (S)-3-(4-chlorophenyl) glutaric acid monomethyl ester (0.35g, 1.37mmol) was dissolved in anhydrous benzene (20mL), and diphenylphosphoryl azide (DPPA ) (0.57g, 2.00mmol) and Et 3 N (0.21g, 2.0mmol), reflux reaction for 7h, cooled to room temperature, room temperature reaction overnight. Anhydrous methanol (0.15g, 4.67mmol) was added dropwise, and the reaction was refluxed for 10h. Cool to room temperature, concentrate under reduced pressure, add ethyl acetate, saturated NaHCO 3 washing, washing with water, washing with 5% HCl, washing with water, drying, and concentration to obtain a crude product. Column chromatography (cyclohexane / ethyl acetate=3:1) gave yellow oil (S)-3-(4-chlorophenyl)-4-methoxycarbonylaminobutyric acid methyl ester 0.24g, yield : 62%. 1 H NMR (500MHz, CDCl 3 ):δ2.46–2.63(m,2H),3.20–3.22(m,2H),3.38(m,1H),3.49(s,3H),3.51(s,3H),4.70(brs,1H), 7.04(d,J=8.5Hz,2H),7.18(d,J=8.5Hz,2H); 13 C NMR (125MHz, CDCl 3 ):38.00,41.68,45.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com