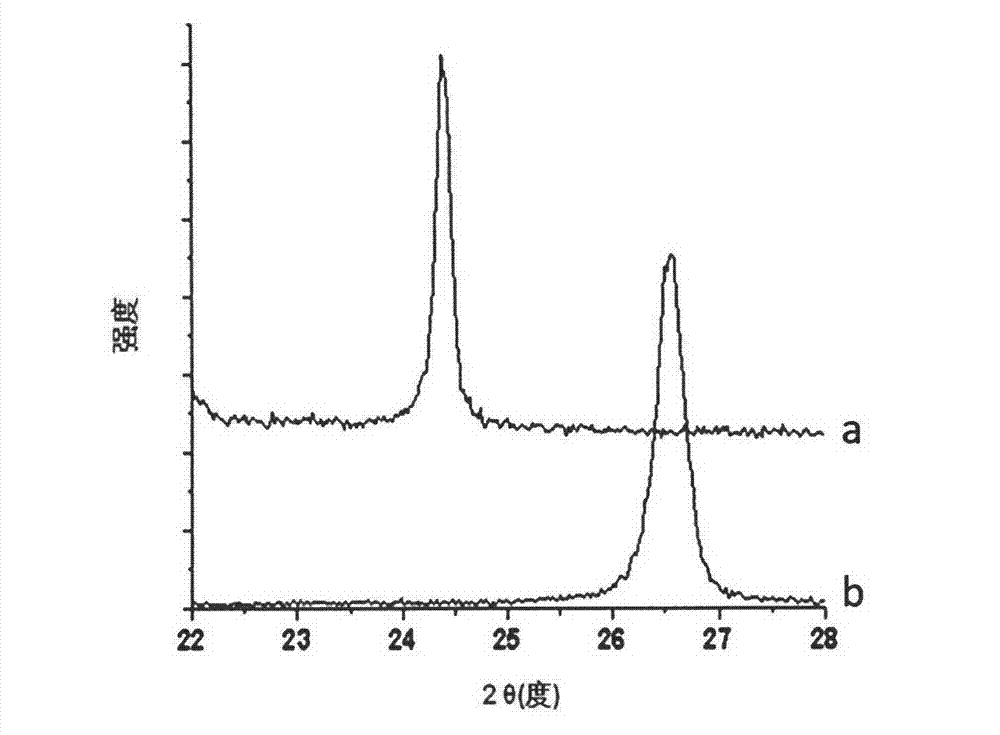

Method for preparing graphene through waste lithium batteries

A waste lithium battery and graphene technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of waste of resources, pollution of the environment, etc., and achieve the effect of avoiding waste, rich sources, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

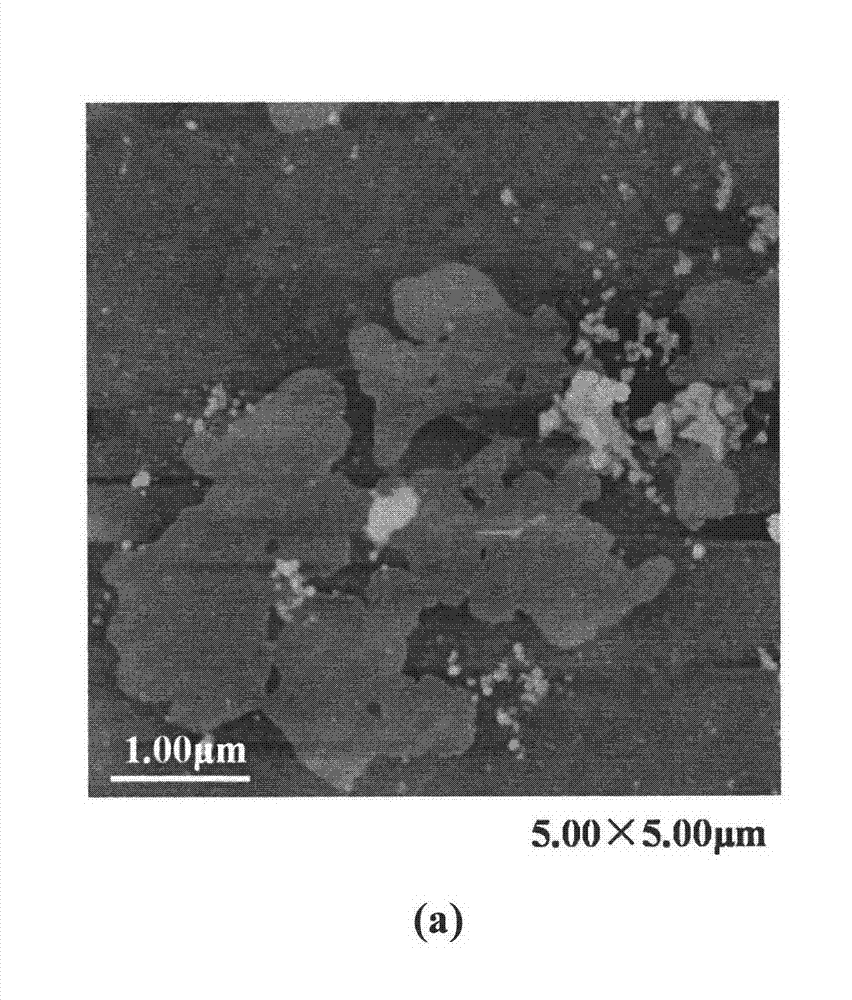

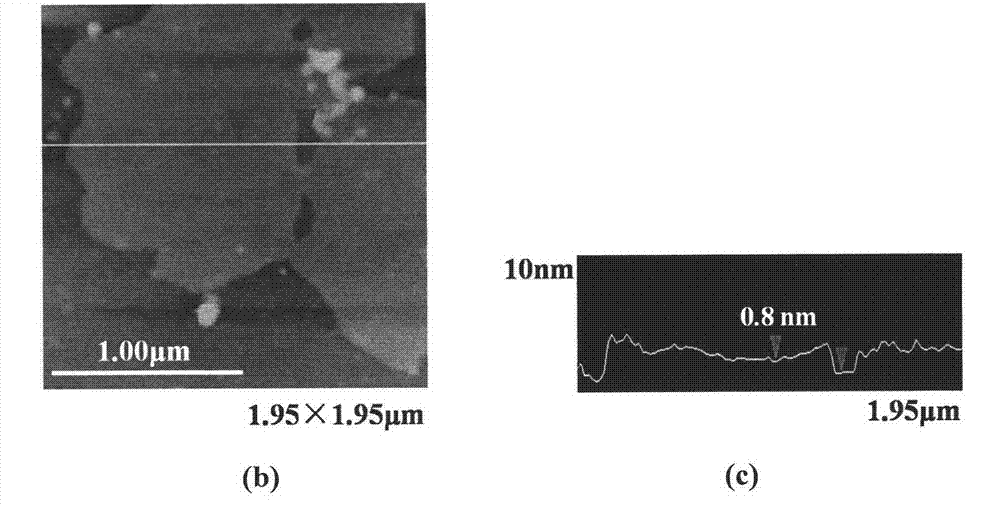

Examples

Embodiment 1

[0045] Using Discharged Lithium Metal Batteries

[0046] The waste lithium metal battery used is to use graphite electrode as positive pole, metal lithium sheet as battery negative pole, lithium hexafluorophosphate is dissolved in EC / EMC / DMC (ethylene carbonate / ethyl methyl carbonate / dimethyl carbonate) with a volume ratio of 1:1:1 ) solution in the ternary mixed solvent is used as the electrolyte, and the diaphragm adopts a polypropylene porous membrane. Among them, the graphite electrode is made by combining special spherical graphite SSG (active material) (obtained from Hunan Loudi Huiyu Technology Co., Ltd.), acetylene black (conductive agent, particle size: about 10nm), polyvinylidene fluoride PVDF (binder) Mix according to the mass ratio of 8:1:1, add 1-methyl-2-pyrrolidone (NMP) to make the concentration of PVDF in the range of 0.005-0.03g / ml, stir well, and adjust to paste slurry. Spread it evenly on the copper foil, and use a puncher to make it after the solvent is c...

Embodiment 2

[0054] Direct use of waste lithium metal batteries

[0055] Except that waste batteries are not discharged, all the other operations are the same as in Example 1, and the resulting graphene yield is 0.51%, and the thickness of the graphene obtained is between 2.4 and 9.2, that is, the number of layers is between about 6 and 26 layers, and the length and width are between 120~6300nm, the intensity ratio of D peak and G peak in Raman spectrum I D / I G The value is 0.68.

Embodiment 3

[0057] Using recharged spent Li-ion batteries

[0058] The positive electrode active material of the waste lithium ion battery used is lithium cobalt oxide, and the negative electrode active material is natural graphite 918. The used lithium ion battery voltage is 3.7V. Specifically, the charging operation is that the battery is charged at a constant current at a charging rate of 0.2C until the battery voltage rises to 4.2V. Then charge the battery at a constant voltage until the charging rate drops to 0.02C, and then charge the battery with a constant current at a charging rate of 0.2C to 4.35V, then charge it at a constant voltage until the charging rate drops to 0.02C (test instrument Such as: BTS high-precision battery testing system (manufactured by China Xinwei Electronics Co., Ltd.), model: CT-3008W-5V10mA-S1).

[0059] Then stop charging, disassemble the battery in a glove box with water and oxygen content less than 1ppm, and take out the first-order lithium-graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com