Porous degradable blood vessel and preparation method thereof

A vascular and wet spinning technology, applied in the directions of vascular, wet spinning, rayon manufacturing, etc., can solve the problems that whole-cell biological blood vessels cannot be widely used, easy to cause thrombosis, and long time, and achieve no allergic reaction, Reduce patient pain, good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of spinning solution:

[0034] Dissolve the PCL raw material and PEO together in tetrahydrofuran, and stir with a magnetic stirrer at 10°C to form a uniform and transparent spinning solution. The total number of parts by weight of PCL and PEO is 10; The number of THF parts is 90; The weight ratio of PCL and PEO is 4: 1;

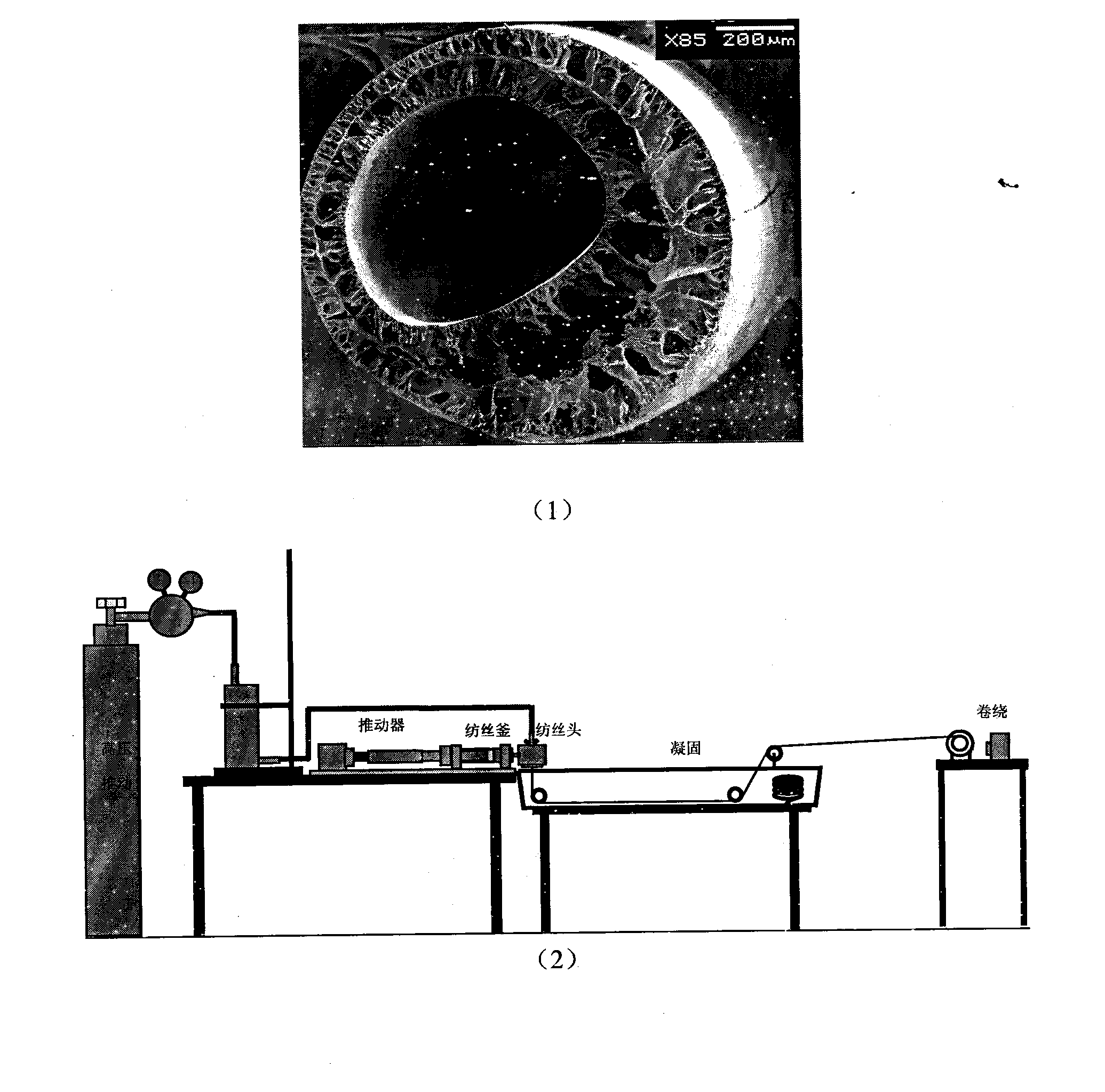

[0035] Hollow fiber preparation:

[0036] Let the spinning solution stand for half an hour for defoaming and then inject it into the spinning kettle, and connect it to the figure 1 On the electric thruster shown; then install the spinning head, inject acetone, open the high-pressure nitrogen bottle that drives the flow of acetone, and start the propeller again when the flow of the core liquid is stable. Perform wet spinning.

[0037]Wet spinning is carried out, the hollow fiber is received in a coagulation bath with a weight ratio of water and acetone of 50 / 50, the fiber is pulled through a godet roller and a godet roller, and wound onto...

Embodiment 2

[0041] Preparation of spinning solution:

[0042] Dissolve the PCL raw material and PVP together in chloroform, and stir with a magnetic stirrer at 50°C to form a uniform and transparent spinning solution. The total parts by weight of PCL and PVP is 40; The parts of chloroform are 60; The weight ratio of PCL and PVP is 1: 4;

[0043] Hollow fiber preparation:

[0044] Let the spinning solution stand for half an hour for defoaming and then inject it into the spinning kettle, and connect it to the figure 1 On the screw propeller shown; then install the spinning head, inject acetone, open the high-pressure carbon dioxide bottle that promotes the flow of ethanol, and start the propeller again when the flow of the core liquid is stable. Perform wet spinning.

[0045] Wet spinning is carried out, the hollow fiber is received in a coagulation bath with a weight ratio of water and acetone of 100 / 0, the fiber is pulled through a godet roller and a godet roller, and wound onto a wind...

Embodiment 3

[0049] Preparation of spinning solution:

[0050] Dissolve the PCL raw material and PVA in methyl formate, and stir with a magnetic stirrer at 100°C to form a uniform and transparent spinning solution. The total number of parts by weight of PCL and PVA is 20; The number of methyl formate parts is 80; The weight ratio of PCL and PVA is 9: 1;

[0051] Hollow fiber preparation:

[0052] Let the spinning solution stand for half an hour for defoaming and then inject it into the spinning kettle, and connect it to the figure 1 On the electric thruster shown; then install the spinning head, inject acetone, open the high-pressure carbon dioxide bottle that drives the flow of acetone, and start the propeller again when the flow of the core liquid is stable. Perform wet spinning.

[0053] Wet spinning is carried out, the hollow fiber is received with an acetone coagulation bath, the fiber is drawn through godet rollers and godet rollers, and wound onto a winder. When the fibers are u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com