Method for extracting kaempferitrin from prunus cerasifera leaves

A technology of kaempferol and purple leaf plum is applied in the field of natural product chemistry to achieve the effects of large processing capacity and low extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Weigh 200g of dried purple-leaf plum leaves and crush them. Put the 40-mesh sieve into a 5000ml beaker, add 2000ml of 70% (V / V) ethanol aqueous solution, seal it with plastic wrap, and place it at room temperature for 12 hours. Min speed stirring 2h, filter, collect the filtrate.

[0023] Add 1000ml of 70% (V / V) ethanol water solution to the filter cake, stir at 600r / min for 20min, and then filter. The filter cake is treated once more according to the above method, and the above three filtrates are combined to obtain the extract.

[0024] 2. Concentrate the extract solution in a water bath at 59°C under reduced pressure to 500ml, place it at 2°C for 12 hours, centrifuge (4000r / min, 30min) to remove most of the fat-soluble substances to obtain a centrifuge solution, and distill the centrifuge solution with distilled water Dilute to 2000ml.

[0025] 3. Chromatography on a macroporous resin column at a flow rate of 3ml / min (HPD400A macroporous adsorption resin from Zhe...

Embodiment 2

[0035] Steps 1 and 2 are the same as in Example 1.

[0036] 3. Chromatography on a macroporous resin column at a flow rate of 4ml / min (HPD400A macroporous adsorption resin from Zhengzhou Qinshi Technology Co., Ltd., with a specific surface area of 500-550m 2 / g, the polarity is medium polarity, the glass column model is Φ3.0*L100cm), at the same flow rate, wash the column with 3000ml distilled water.

[0037] 4. Use 30% (V / V) ethanol aqueous solution to wash kaempferol from the column at a flow rate of 5ml / min, and collect the fraction between 550 and 1250ml behind the column.

[0038] 5. The distillate was crystallized at 3°C for 8 days, and filtered after crystallization to obtain the crude crystalline product and mother liquor.

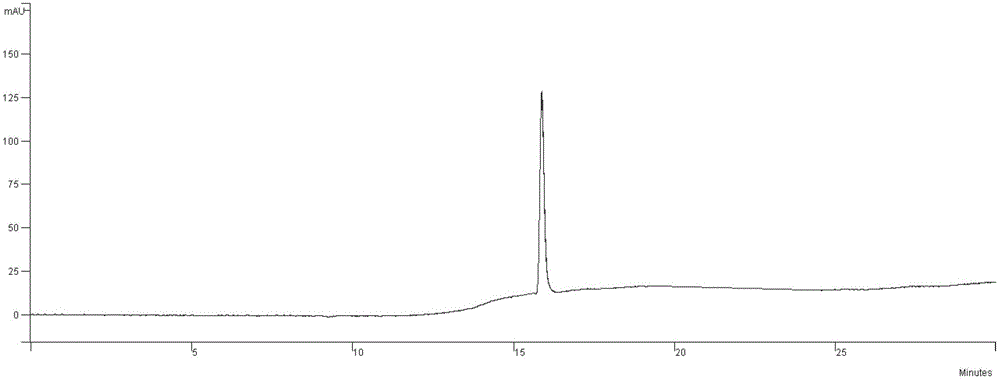

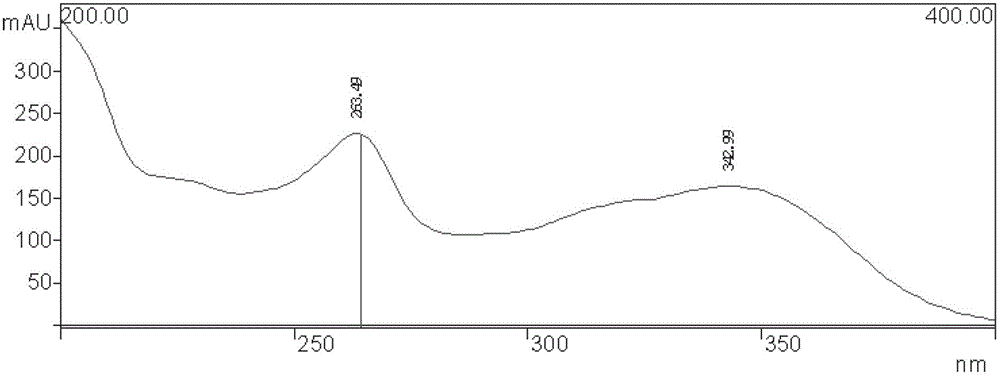

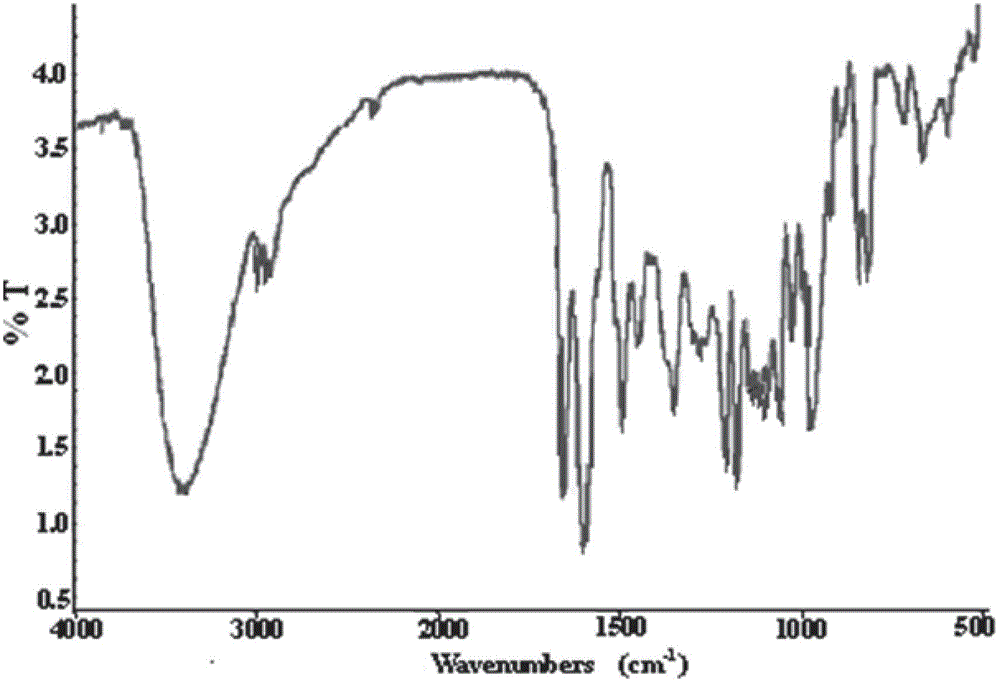

[0039] 6. The crude product of the crystalline substance was washed with water and vacuum-dried at room temperature to obtain the kaempferi product (qualified and quantified by HPLC external standard method, its content ≥ 98%). Step 3, repeat...

Embodiment 3

[0042] Steps 1 and 2 are the same as in Example 1.

[0043] 3. Chromatography on a macroporous resin column at a flow rate of 5ml / min (HPD400A macroporous adsorption resin from Zhengzhou Qinshi Technology Co., Ltd., with a specific surface area of 500-550m 2 / g, the polarity is medium polarity, the glass column model is Φ3.0*L100cm), at the same flow rate, wash the column with 3000ml distilled water.

[0044]4. Use 30% (V / V) ethanol aqueous solution to wash kaempferol from the column at a flow rate of 5ml / min, and collect the fraction between 550 and 1250ml behind the column.

[0045] 5. The distillate was crystallized at 0°C for 7 days, and filtered after crystallization to obtain the crude crystalline product and mother liquor.

[0046] 6. The crude product of the crystalline substance was washed with water and vacuum-dried at room temperature to obtain the kaempferi product (qualified and quantified by HPLC external standard method, its content ≥ 98%). Step 3, repeating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com