Solvent-free high-elasticity epoxy self-leveling coating and preparation method thereof

A high-elasticity, self-leveling technology, used in epoxy resin coatings, coatings, etc., can solve problems such as poor dynamic load bearing capacity, affecting the performance of coatings, and easy scratches on the floor surface, to improve impact strength and Toughness, excellent surface finish, improved scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of solvent-free highly elastic epoxy self-leveling coating of the present invention mainly comprises the following steps:

[0037] a: Weigh bisphenol A type epoxy resin, bisphenol F type epoxy resin, monofunctional epoxy reactive diluent and multifunctional epoxy reactive diluent according to the above ratio, and place them in a mixer at 500-800 Stir at room temperature and pressure for 10-20 minutes at a speed of rpm;

[0038] b: uniformly add a toughening agent to the mixture in step a, and stir for 15-30 minutes at a speed of 200-400 rpm under normal temperature and pressure;

[0039] c: Keep the mixture in step b in a stirring state of 600-1000 rpm, and evenly add wetting and dispersing agent, leveling agent and defoamer to the mixture, and stir at normal temperature and pressure for 20-30 minutes;

[0040] d: Add inorganic fillers to the mixture in step c, and stir at a speed of 2000-3000 rpm for 20-40 minutes at normal temperature and press...

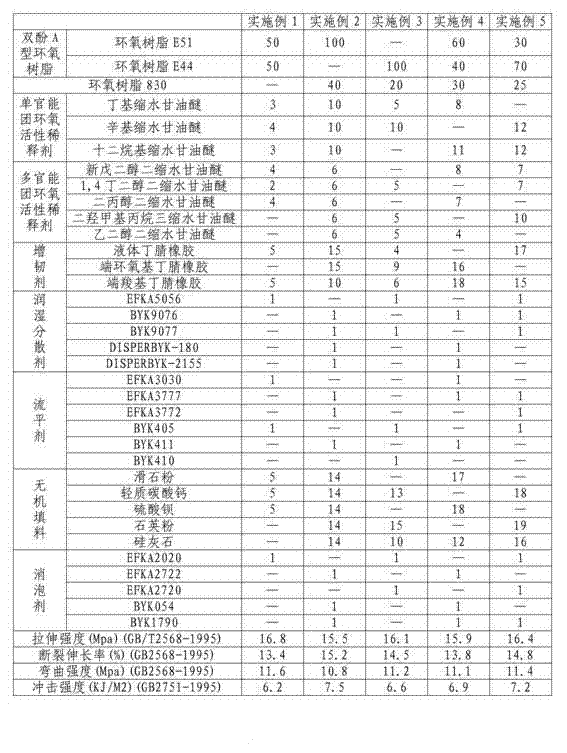

Embodiment 1

[0045] The solvent-free highly elastic epoxy self-leveling coating of the present invention comprises bisphenol A type epoxy resin, monofunctional epoxy reactive diluent, multifunctional epoxy reactive diluent, toughening agent, inorganic filler, wetting and dispersing agent, fluid Leveling agent and defoamer. Wherein the bisphenol A epoxy resin is a mixture of epoxy resin E51 and epoxy resin E44; the monofunctional epoxy reactive diluent is a mixture of butyl glycidyl ether, octyl glycidyl ether and dodecyl glycidyl ether; The functional epoxy reactive diluent is a mixture of neopentyl glycol diglycidyl ether, 1,4 butanediol diglycidyl ether and dipropanol diglycidyl ether; the toughening agent is liquid nitrile rubber and carboxy-terminated nitrile rubber Mixture; the wetting and dispersing agent is EFKA5056 of Efka Company of the Netherlands; the leveling agent is a mixture of EFKA3030 of Efka Company of the Netherlands and BYK405 of BYK Company of Germany; the inorganic fi...

Embodiment 2

[0054] The solvent-free highly elastic epoxy self-leveling coating of the present invention comprises bisphenol A type epoxy resin, bisphenol F type epoxy resin, monofunctional epoxy reactive diluent, multifunctional epoxy reactive diluent, toughening agent, inorganic Filler, wetting and dispersing agent, leveling agent and defoamer. Among them, the bisphenol A type epoxy resin is epoxy resin E51; the bisphenol F type epoxy resin is epoxy resin 830; the monofunctional epoxy reactive diluent is butyl glycidyl ether, octyl glycidyl ether and dodecane Glycidyl ether mixture; polyfunctional epoxy reactive diluents are neopentyl glycol diglycidyl ether, 1,4 butanediol diglycidyl ether, dipropanol diglycidyl ether, dimethylolpropane triglycidyl ether A mixture of ether and ethylene glycol diglycidyl ether; the toughening agent is a mixture of liquid nitrile rubber, epoxy-terminated nitrile rubber and carboxyl-terminated nitrile rubber; the wetting and dispersing agent is BYK9076, BY...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com