Manganese alloy target material and its manufacturing method

A manufacturing method, manganese alloy technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problem of not proposing a solution to target brittleness, manganese alloy target material is difficult to prepare in batches, and the fracture strength is low and other problems to achieve the effect of high density, precise composition and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

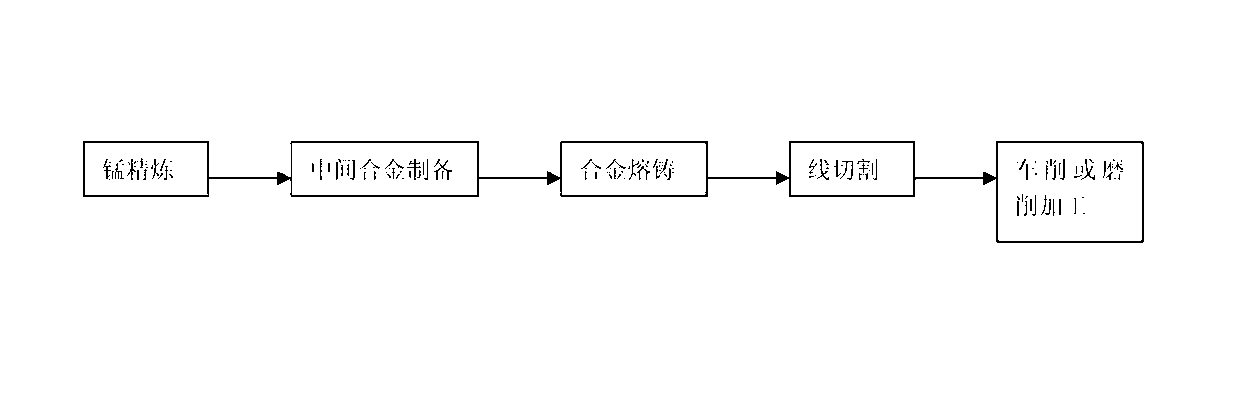

Method used

Image

Examples

Embodiment 1

[0037] Prepare MnPt72.2 manganese alloy sputtering target, comprising the following steps:

[0038] (1) 3 kg of domestically produced manganese flakes with a purity of 99.99% were subjected to three repetitions of electron beam melting under an inert gas atmosphere. The obtained manganese ingot 850g is preserved under inert gas environment;

[0039] (2) Manganese ingots and Pt blocks with a purity of 99.99% are made into an intermediate alloy with a manganese content of 60% (mass%, the following alloy contents are all mass ratios), melted by vacuum induction melting in an inert gas environment, and cast The mold is a copper mold;

[0040] (3) Polish the surface of the master alloy, and take about 0.5g of chips from the upper, middle and lower sections of the ingot to analyze its manganese content by ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometer). The results are shown in Table 1 below . Take the average value of 53.7% as the manganese content of the mast...

Embodiment 2

[0052] Prepare MnPd25.6 manganese alloy sputtering target, comprising the following steps:

[0053] (1) 5 kg of manganese flakes with a purity of 99.999% were subjected to three repetitions of electron beam melting in a vacuum atmosphere. Manganese ingots obtained;

[0054] (2) Manganese ingots and Pd blocks with a purity of 99.999% are made into an intermediate alloy with a manganese content of 85%, and vacuum induction melting is carried out in an inert gas environment;

[0055] (3) About 0.5 g of chips were taken from the upper, middle and lower sections of the ingot to analyze the manganese content by ICP-OES. The results are shown in Table 3 below. Take the average value of 81.2% as the manganese content of the master alloy, and add Pd blocks to make the Pd content after batching meet the requirements of the finished product;

[0056] Table 3. Manganese content in different parts of the master alloy

[0057] Alloy parts Upper (%) Central (%) Lower part ...

Embodiment 3

[0065] Prepare the MnIr50 manganese alloy sputtering target, comprising the following steps:

[0066] (1) Manganese flakes with a purity of 99.9% were subjected to electron beam melting twice under an inert gas atmosphere. The obtained manganese ingots are preserved under an inert gas environment;

[0067] (2) Manganese ingots and Ir powder with a purity of 99.9% are formulated into a master alloy with a manganese content of 65%, and the master alloy ingot is melted and cast by electron beam melting under vacuum;

[0068] (3) Remove the outer skin of the master alloy, and take about 0.5 g of chips from the upper, middle and lower sections of the ingot to analyze the manganese content by ICP-OES. The results are shown in Table 5 below. Take the average value of 55.2% as the manganese content of the master alloy, and add Ir blocks to make the Ir content after batching meet the requirements of the finished product;

[0069] Table 5. Manganese content in different parts of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Warping | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com