Preparation method of CdS/carbon nano tube/polyacrylonitrile hybrid nano-fiber

A carbon nanotube and polyacrylonitrile technology, applied in the field of nanomaterials, can solve the problems of low bonding strength, easy to fall off, and CdS particles are easy to agglomerate, and achieve the effects of good mechanical properties, inhibition of agglomeration, and easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

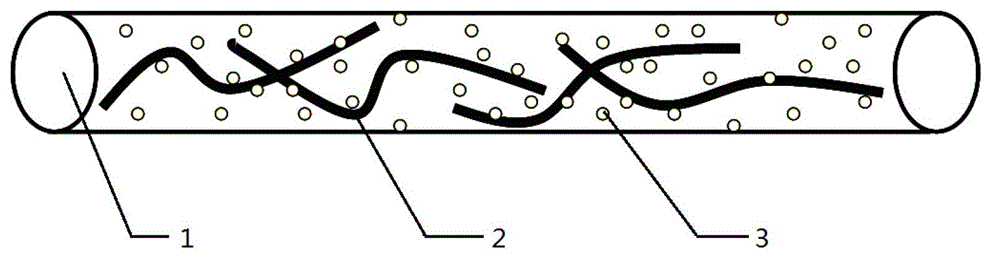

Image

Examples

Embodiment 1

[0027] (1) Preparation of CdS-OH / DMF suspension

[0028] ①Under magnetic stirring, drop 30 mL of DMF solution containing 5 mmol 2-mercaptoethanol (ME) into 3 mL of 2.5 mmol CdCl 2 in the aqueous solution, and stirred for 10 min to obtain A solution.

[0029] ② Add 3 mL of 1.5 mmol Na 2 The aqueous solution of S was added dropwise to the solution of A, at this time, the colorless and transparent solution immediately turned yellow and gradually became turbid. After the mixed solution was reacted at 30° C. for 4 hours, the yellow solution became clear and transparent again, and solution B was obtained.

[0030] ③Transfer the B solution to a rotary evaporator and carry out vacuum distillation at 85°C to remove water and a small part of DMF. After vacuum distillation, the precipitated NaCl was removed by centrifugation to obtain a clear and transparent CdS-OH / DMF suspension with a mass concentration of 1.2%.

[0031] (2) Preparation of electrospinning solution

[0032]①Dissolv...

Embodiment 2

[0039] (1) The preparation of CdS-OH / DMF suspension is the same as in Example 1

[0040] (2) Preparation of electrospinning solution

[0041] ① Dissolve 1.5 g of PAN in 11.0 g of DMF to make a clear solution, then add 0.83 g of acetone and 0.0044 g of cetyltrimethylamine bromide (CTAB) into the solution to make a mass concentration composition of 11% PAN, 6.1% Acetone, 0.03% CTAB in C.

[0042] ② Add 0.008 g of MWCNT to 6.61 g of 1.2% CdS-OH / DMF suspension, magnetically stir for 30 min, and sonicate in an ultrasonic oscillator for 3 hours to make a uniform black suspension D.

[0043] ③ Slowly add the suspension D to the C solution under magnetic stirring, stir for 30 min and then sonicate in an ultrasonic oscillator for 3 hours. 20 g of uniform and stable CdS-OH / MWCNT / PAN spinning solution with a mass concentration composition of 7.5% PAN, 0.4% CdS-OH and 0.04% MWCNT was obtained.

[0044] (3) Preparation of CdS-OH / MWCNT / PAN hybrid nanofibers

[0045] Transfer the CdS-OH / ...

Embodiment 3

[0048] (1) The preparation of CdS-OH / DMF suspension is the same as in Example 1

[0049] (2) Preparation of electrospinning solution

[0050] ① Dissolve 1.5 g of PAN in 11.0 g of DMF to make a clear solution, then add 0.83 g of acetone and 0.0044 g of cetyltrimethylamine bromide (CTAB) into the solution to make a mass concentration composition of 11% PAN, 6.1% Acetone, 0.03% CTAB in C.

[0051] ②Add 0.008 g of single-walled carbon nanotubes (SWCNTs) to 6.65 g of 1.2% CdS-OH / DMF suspension, magnetically stir for 30 min, and ultrasonicate for 3 hours in an ultrasonic oscillator to make a uniform black suspension D.

[0052] ③ Slowly add the suspension D to the C solution under magnetic stirring, stir for 30 min and then sonicate in an ultrasonic oscillator for 3 hours. 20 g of uniform and stable CdS-OH / SWCNT / PAN spinning solution with a mass concentration of 7.5% PAN, 0.4% CdS-OH and 0.04% MWCNT was obtained.

[0053] (3) Preparation of CdS-OH / SWCNT / PAN hybrid nanofibers

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com