Ammonium sulfate production system and preparation method thereof

A production system and ammonium sulfate technology, applied in the field of ammonium sulfate, can solve problems such as increasing production costs and environmental pollution, and achieve the effects of reducing pollution, eliminating the release of waste ammonia gas, and expanding the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

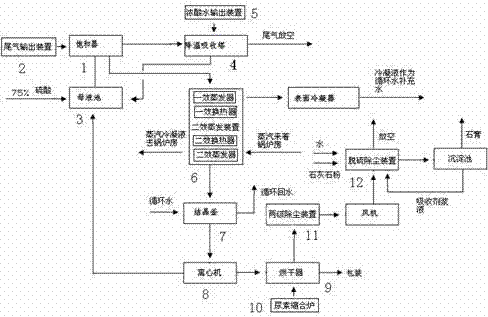

[0019] The present invention provides a kind of ammonium sulfate production system, and this system comprises the saturator 1 that is used to generate ammonium sulfate, and this saturator 1 is respectively connected with the tail gas output device 2 of the ammonia-containing tail gas that cyanuric acid device produces, the mother liquor pool 3 of splendid attire sulfuric acid , the cooling absorption tower 4 that removes ammonia in the tail gas is connected, and the cooling absorption tower 4 is also connected with the concentrated acid water output device 5 and the mother liquor pool 3 of the concentrated acid water generated by the cyanuric acid device, and the saturator 1 is also connected with the second effect evaporation The device 6, the crystallization kettle 7, the centrifuge 8, and the dryer 9 are connected in sequence. Wherein the second-effect evaporator 6 comprises a first-effect evaporator and a corresponding first-effect heat exchanger, a second-effect evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com