Solution polymerization method

A polymerization method and solution technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of long initiator induction period, long time, and inability to obtain ultra-high molecular weight acrylamide polymers, etc., and achieve shortened polymerization Reaction time, effect of eliminating polymerization inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

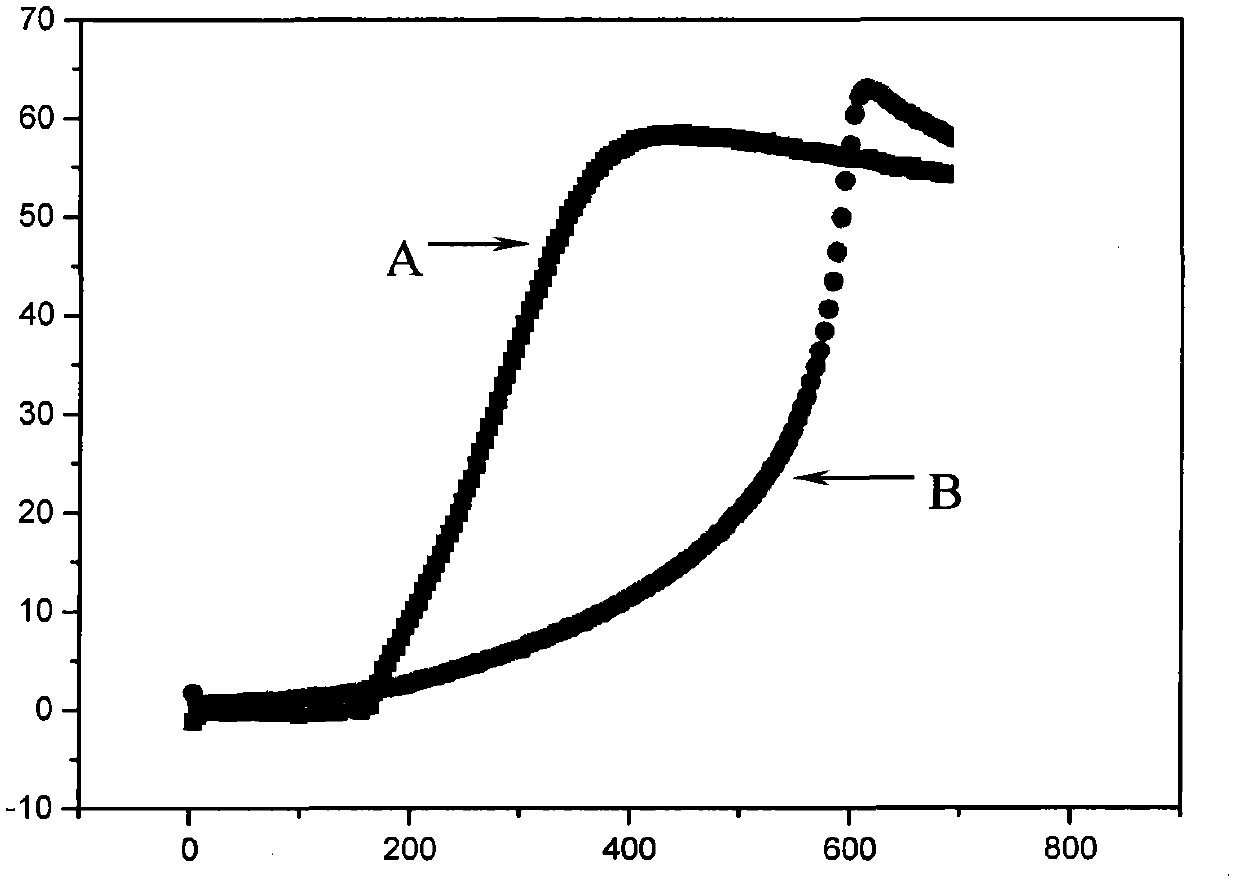

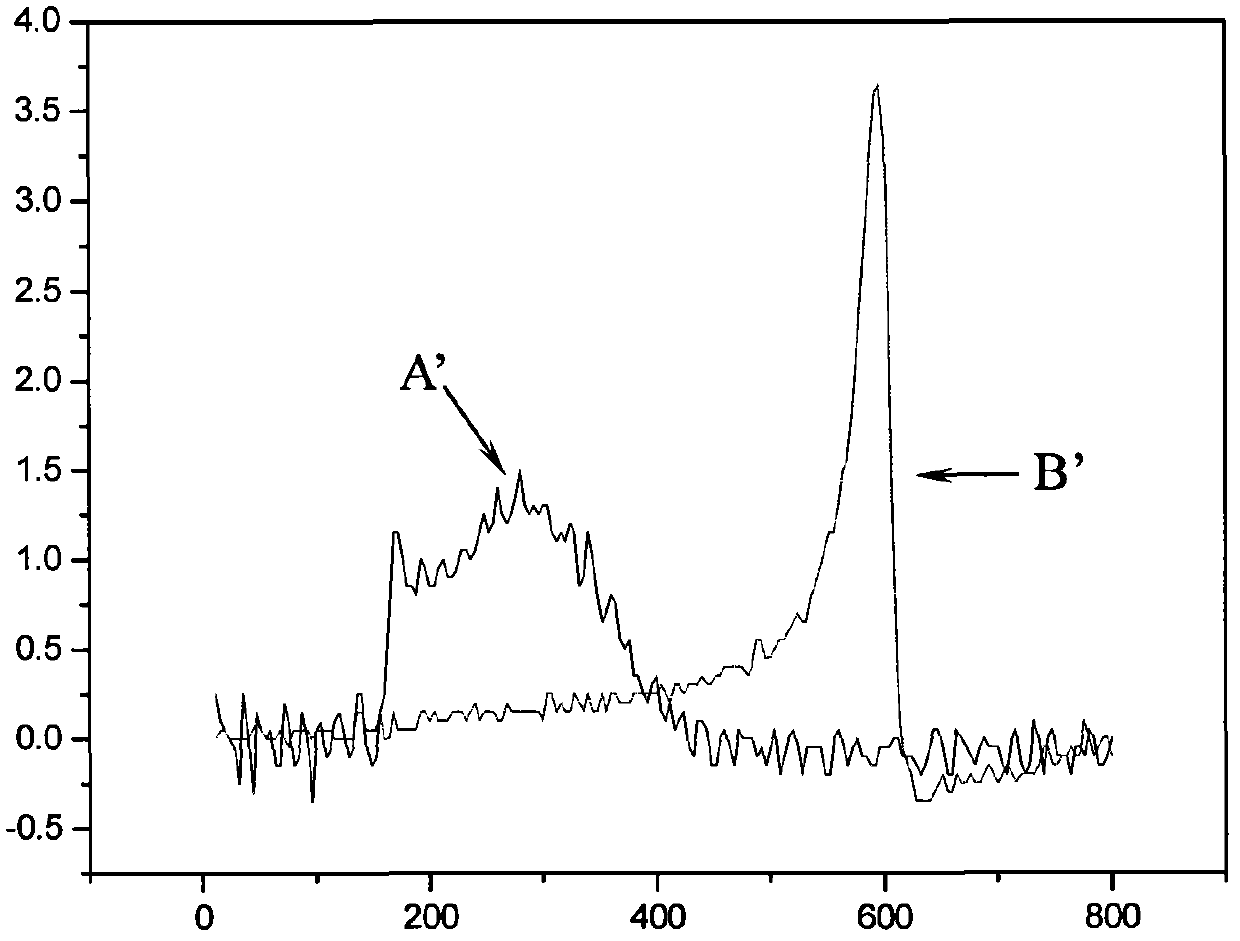

Image

Examples

Embodiment 1

[0041] (1) 150g acrylamide (AM), 150g 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 29g sodium hydroxide solid are mixed with 700g water under stirring, the aqueous solution obtained after mixing is cooled to 0 ℃, use mass concentration 20% by weight sodium hydroxide solution to adjust the pH value of the aqueous solution to 8.2, then add 0.07g EDTA disodium salt, 0.07g urea, 0.01g V50, 1mL mass concentration of 1% by weight to the aqueous solution Tetramethylethylenediamine solution, using the oxi3210 type dissolved oxygen meter (the same below) of German WTW company to measure the concentration of dissolved oxygen in the aqueous solution is 14.5ppm.

[0042] (2) Move the aqueous solution obtained in step (1) into a Dewar flask with a capacity of 1.5 L and add a thermocouple for recording the reaction temperature, keep the temperature of the aqueous solution at 0 ° C, and connect the aqueous solution with 0.09 g of solid under electromagnetic stirring Sodium sulfite was m...

Embodiment 2

[0051] (1) 225g of acrylamide (AM), 75g of acrylic acid (AAc), 40g of sodium hydroxide and 700g of water are mixed under stirring, the aqueous solution obtained after mixing is cooled to 10°C, and a sodium hydroxide solution with a mass concentration of 20% by weight is used Adjust the pH value of the aqueous solution to 9, then add 0.01g EDTA disodium salt, 0.02g azobisisopropylimidazoline, 1mL tetramethylethylenediamine solution with a mass concentration of 1% by weight to the aqueous solution, and use the solution The oxygen meter measures the concentration of dissolved oxygen in the aqueous solution to be 11.2ppm.

[0052] (2) Move the aqueous solution obtained in step (1) into a Dewar flask with a capacity of 1.5L and add a thermocouple for recording the reaction temperature, keep the aqueous solution temperature at 10°C, and connect the aqueous solution with 0.12g solid under electromagnetic stirring Sodium sulfite was mixed, and 0.2 ml of potassium persulfate solution w...

Embodiment 3

[0054] (1) 202g of acrylamide (AM), 98g of (2-acrylamido) ethyl tetradecyl dimethyl ammonium bromide and 700g of water were mixed under stirring, and the aqueous solution obtained after mixing was cooled to 5°C, Use mass concentration 20% by weight sodium hydroxide solution to adjust the pH value of the aqueous solution to 8, then add 0.01g EDTA disodium salt, 0.02g azobisisopropylimidazoline, 1mL mass concentration 1% by weight of Tetramethylethylenediamine solution, using a dissolved oxygen meter to measure the concentration of dissolved oxygen in the aqueous solution is 12.6ppm.

[0055] (2) Move the aqueous solution obtained in step (1) into a Dewar flask with a capacity of 1.5L and add a thermocouple for recording the reaction temperature, keep the aqueous solution temperature at 5°C, and dilute the aqueous solution with 0.05g solid under electromagnetic stirring Sodium sulfite was mixed, and after 1.5 minutes, 0.15 ml of potassium persulfate solution with a mass concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com