Ceramic powder for electronic component packaging material and production method for ceramic powder

A technology of electronic components and packaging materials, applied in the field of electronic ceramic materials, can solve the problems of unsuitable packaging of electronic components and substrate materials, unsuitable for industrialized mass production, poor product performance, etc., and achieve low production cost and excellent comprehensive performance , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

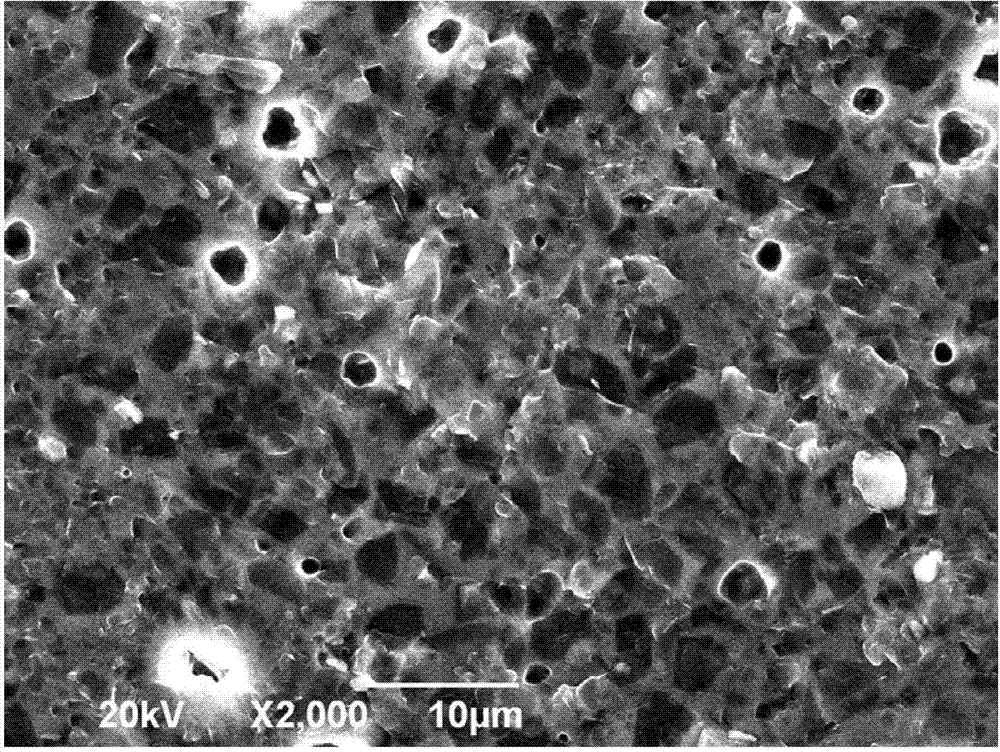

[0022] Embodiment 1: weigh 60kg BaO, 9kg B 2 o 3 , 23kg SiO2 2 、3kg Al 2 o 3 , 5kg TiO2 2 , placed together in a ball mill, with ethanol as the ball milling agent and zirconium balls as the ball, after 3 hours of ball milling, drying at 70°C, and sieving to obtain a powder with an average particle size of 4.3 μm; sintering at 750°C And after 1.5 hours of heat preservation, the powder after grinding and sieving is the composite oxide; then weigh 45kg of composite oxide, 55kg of quartz (125μm) and place it in the ball mill for 11 hours after wet grinding. Drying under high pressure until the moisture content is ≤0.5%, and sieving to obtain a white powder with an average particle size of 3.0 μm, which is ceramic powder for electronic packaging materials.

[0023] After the above ceramic powder is pressed and formed at 20MPa, it is sintered in the air and at a temperature of 970°C and kept for 1 hour, and the coefficient of thermal expansion is 18.3×10 -6 / °C (25-400°C) cera...

Embodiment 2

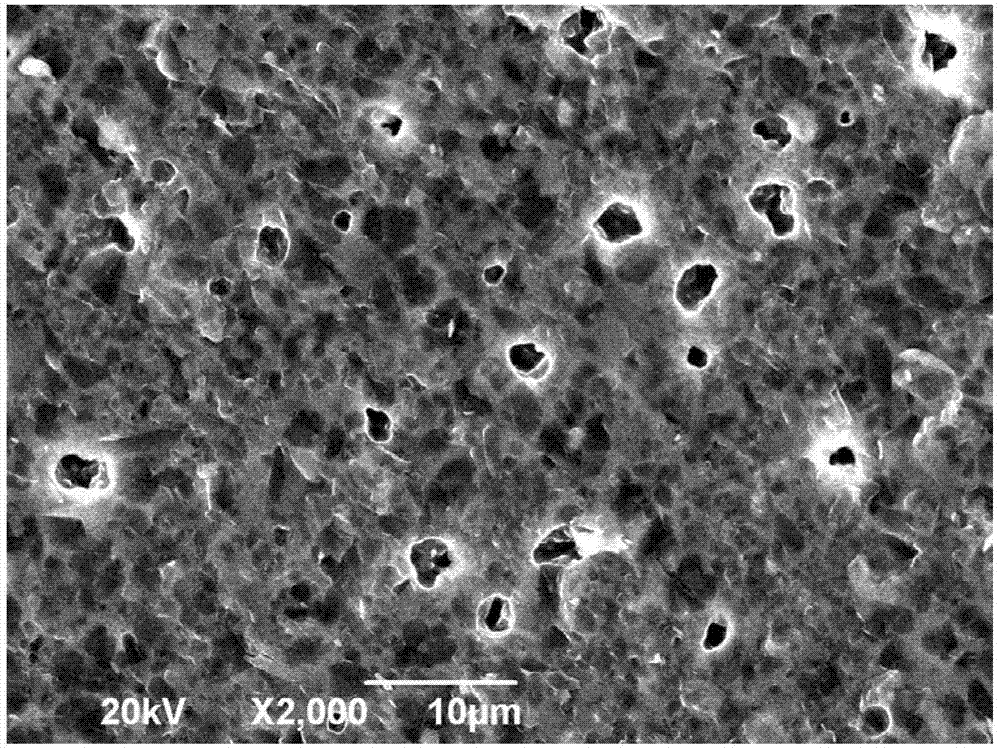

[0024] Embodiment 2: weigh 52kg BaO, 10kg B 2 o 3 、30kg SiO2 2 、5kg Al 2 o 3 , 3kg ZrO 2 and 1kg Co 2 o 3 Put them together in a ball mill, use deionized water as the ball milling agent, and zirconium balls as the balls, after 5 hours of ball milling, dry at 100°C, sieve to obtain a powder with an average particle size of 3.5μm, and then grind at 750°C sintering and heat preservation for 2 hours, and then the powder after grinding and sieving is the composite oxide; then weigh 57kg of the composite oxide and 43kg of quartz (105μm), and place them in the ball mill for 9 hours after wet grinding. Dry at 100°C until the moisture content is ≤1%, and the blue powder with an average particle size of 2.5 μm obtained through sieving is the ceramic powder for electronic packaging materials.

[0025] After the above-mentioned ceramic powder is pressed and formed at 20MPa, in a reducing atmosphere N 2 +H 2 Sintering at a temperature of 950°C and holding for 1.5 hours to obtain a...

Embodiment 3

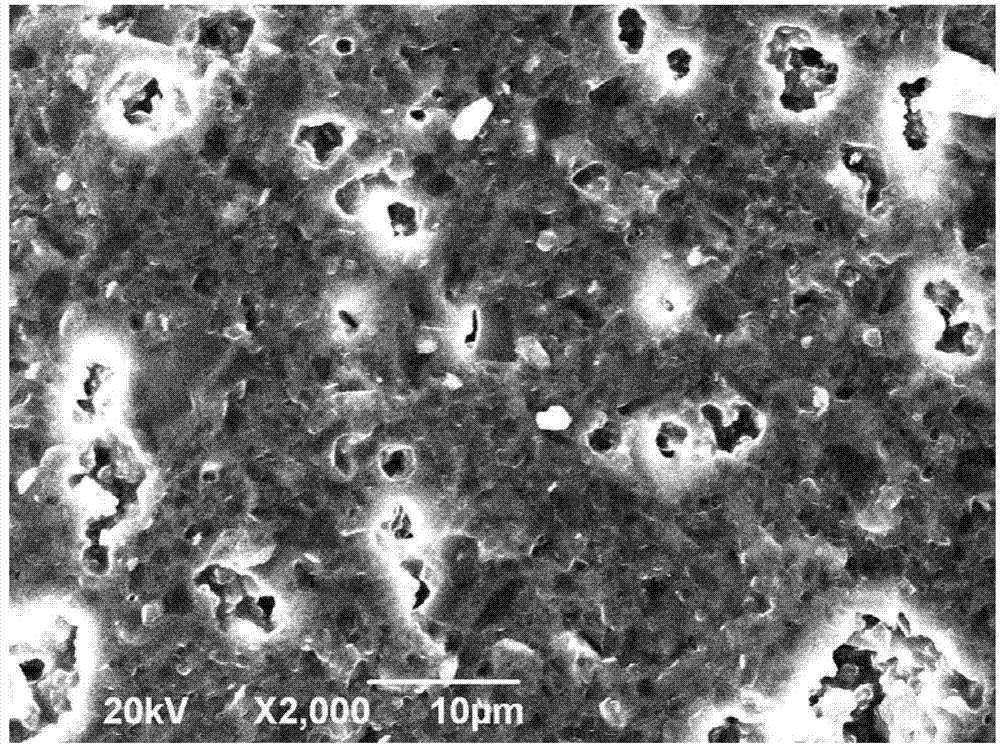

[0026] Embodiment 3: weigh 16kg BaO, 5kg B 2 o 3 , 52kg SiO2 2 、5kg Al 2 o 3 , 15kg MgO, 7kg ZrO 2 Put them together in a ball mill, use a mixture of ethanol and deionized water at a ratio of 7:3 as the ball milling agent, and zirconium balls as the balls, after 7 hours of ball milling, dry at 80°C, and sieve to obtain an average particle size of 2.8 μm powder; then sintered at 750°C and held for 2.5 hours, then ground and sieved to form the composite oxide powder; then weigh 73kg of composite oxide, 27kg of quartz (74μm) and 0.5kg of Cr 2 o 3 Using a mixture of ethanol and deionized water at a ratio of 7:3 as the ball milling agent and zirconium balls as the balls, after 7 hours of ball milling, dry at 80°C until the moisture content is ≤1%, and sieve to obtain a powder with an average particle size of 2.1 μm. The green powder is ceramic powder for electronic packaging materials.

[0027] After the above-mentioned ceramic powder is pressed and formed at 20MPa, in a red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Insulation resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com