Biological grease in algae cell and preparation method and application of biological grease

A technology of algae cells and bio-oil, which is applied in the field of biodiesel preparation, can solve the problems that the production scale and output are difficult to meet the huge demand, and achieve the effects of easy automatic control, simple equipment process and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

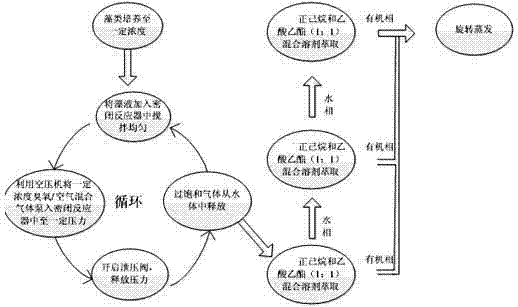

Method used

Image

Examples

Embodiment 1

[0041] A biological oil in algal cells is prepared by a method comprising the following steps:

[0042] (1) Measure 200 ml of harvested algal liquid in a 1 L high pressure reactor, and stir for 5 min at 120 r / min;

[0043] (2) Turn on the ozone generator and air compressor, control the total flow of ozone and air to 2 L / min according to the volume ratio, that is, the ratio of ozone:air to 1:150, and pass the mixed gas composed of ozone and air into the air conditioner. In the autoclave, continue to stir the algae liquid at a constant speed of 120 r / min, so that the introduced ozone, air and the algae liquid are evenly mixed;

[0044] (3) Control the pressure of the autoclave to 0.6 MPa. When it reaches 0.6 Mpa, open the exhaust valve of the autoclave to reduce the pressure to normal pressure, and then increase the pressure to 0.6 MPa. When it reaches 0.6 Mpa, open it again. The exhaust valve of the high-pressure reactor reduces the pressure to normal pressure, and the broken ...

Embodiment 2

[0052] A biological oil in algal cells is prepared by a method comprising the following steps:

[0053] (1) Measure 200 mL of harvested algal liquid in a 1 L high pressure reactor, and stir for 5 min at 120 r / min;

[0054] (2) Turn on the ozone generator and air compressor, control the total flow of ozone and air to 2 L / min according to the volume ratio, that is, the ratio of ozone:air to 1:150, and pass the mixed gas composed of ozone and air into the air conditioner. In the autoclave, continue to stir the algae liquid at a constant speed of 120 r / min, so that the introduced ozone, air and the algae liquid are evenly mixed;

[0055] (3) Control the pressure of the autoclave to 0.6 MPa. When it reaches 0.6 Mpa, open the exhaust valve of the autoclave to reduce the pressure to normal pressure, and then increase the pressure to 0.6 MPa. When it reaches 0.6 Mpa, open it again. The exhaust valve of the high-pressure reactor reduces the pressure to normal pressure, and the broken ...

Embodiment 3

[0063] A biological oil in algal cells is prepared by a method comprising the following steps:

[0064] (1) Measure 200 mL of harvested algal liquid in a 1 L high pressure reactor, and stir for 5 min at 120 r / min;

[0065] (2) Turn on the ozone generator and air compressor, control the total flow of ozone and air to 2 L / min according to the volume ratio, that is, the ratio of ozone:air to 1:150, and pass the mixed gas composed of ozone and air into the air conditioner. In the autoclave, continue to stir the algae liquid at a constant speed of 120 r / min, so that the introduced ozone, air and the algae liquid are evenly mixed;

[0066] (3) Control the pressure of the autoclave to 0.8 MPa. When it reaches 0.8 Mpa, open the exhaust valve of the autoclave to reduce the pressure to normal pressure, and then increase the pressure to 0.8 MPa. When it reaches 0.8 Mpa, open it again. The exhaust valve of the high-pressure reactor reduces the pressure to normal pressure, and the broken ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com