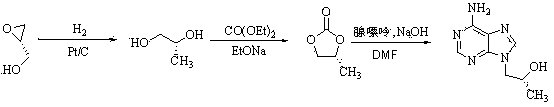

Method for synthesis of PMPA by combining biological technique and chemical technique

A technology of chemical method and biological method, applied in the direction of biochemical equipment and methods, methods based on microorganisms, chemical instruments and methods, etc., can solve the problems of unreachable and high production costs, and achieve simple post-processing and mild reaction conditions , economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

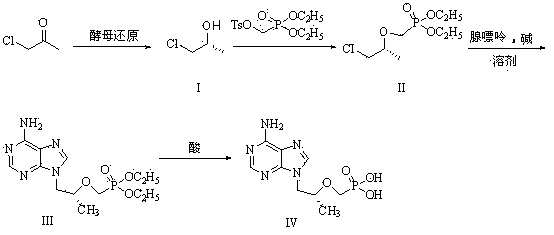

[0029] (1) Preparation of R-chloropropanol (I)

[0030] Add 10g of Angel dry yeast to 150ml of pH=5.91 buffer solution, place the reaction bottle in a shaker at T=35°C, activate for 0.5 hours, add 0.9g of chloroacetone, and use a centrifuge tube to sample once every 0.5h , 3mL each time; after sampling, centrifuge with a centrifuge, the centrifuge speed is: r=4000rpm, time t=20min; after centrifugation, take the supernatant, evaporate to dryness with a rotary evaporator, add methanol to dissolve, let stand ; Do temperament analysis. After the reaction is complete, concentrate by centrifugation, add 50ml of methanol to dissolve, filter and concentrate to obtain 0.65g of chloropropanol (I).

[0031] (2) Preparation of (R)-2-[bis-(isopropyl)-phosphonomethoxy]-propyl chloride (II)

[0032] Put 9.4g (100mmol) of compound (I) in a 200ML three-neck flask, add 100ML of anhydrous THF, under ice-cooling, add 2.88g (120mmol), 60% NaH in batches, stir for 0.5 hours, and then slowly add ...

Embodiment 2

[0038] (1) Preparation of R-chloropropanol (I)

[0039] Add 10g of Angel dry yeast to 150ml of pH=6.98 buffer solution, place the reaction bottle in a shaker at T=35°C, activate for 0.5 hours, add 0.9g of chloroacetone, and take a sample with a centrifuge tube every 0.5h , 3mL each time; after sampling, centrifuge with a centrifuge, the centrifuge speed is: r=4000rpm, time t=20min; after centrifugation, take the supernatant, evaporate to dryness with a rotary evaporator, add methanol to dissolve, let stand ; Do temperament analysis. After the reaction is complete, concentrate by centrifugation, add 50ml of methanol to dissolve, filter and concentrate to obtain 0.80g of chloropropanol (I).

[0040] (2) Preparation of (R)-2-[bis-(isopropyl)-phosphonomethoxy]-propyl chloride (II)

[0041]Put 9.4g (100mmol) of compound (I) in a 200ML three-neck flask, add 100ML of anhydrous THF, under ice-cooling, add 6.0g (150mmol) NaOH in batches, stir for 0.5 hours, then slowly add 38.2g (120...

Embodiment 3

[0047] (1) Preparation of R-chloropropanol (I)

[0048] Add 10g of Angel dry yeast to 150ml of pH=8.04 buffer solution, place the reaction bottle in a shaker at T=35°C, activate for 0.5 hours, add 0.9g of chloroacetone, and use a centrifuge tube to sample once every 0.5h , 3mL each time; after sampling, centrifuge with a centrifuge, the centrifuge speed is: r=4000rpm, time t=20min; after centrifugation, take the supernatant, evaporate to dryness with a rotary evaporator, add methanol to dissolve, let stand ; Do temperament analysis. After the reaction is complete, concentrate by centrifugation, add 50ml of methanol to dissolve, filter and concentrate to obtain 0.89g of chloropropanol (I).

[0049] (2) Preparation of (R)-2-[bis-(isopropyl)-phosphonomethoxy]-propyl chloride (II)

[0050] Put 9.4g (100mmol) of compound (I) in a 200ML three-neck flask, add 100ML of anhydrous THF, under ice-cooling, add 6.0g (150mmol) NaOH in batches, stir for 0.5 hours, then slowly add 38.2g (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com