High-oxygen-content iron-based amorphous composite powder and preparation method thereof

A composite powder, iron-based amorphous technology is applied in the field of preparation of amorphous alloys and composite materials, which can solve the problem of hindering the amorphous transformation of alloy powders, increasing the viscosity of amorphous powders, and reducing the supercooled liquid phase. Area width and other issues, to achieve the effect of saving raw materials, high oxygen content, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

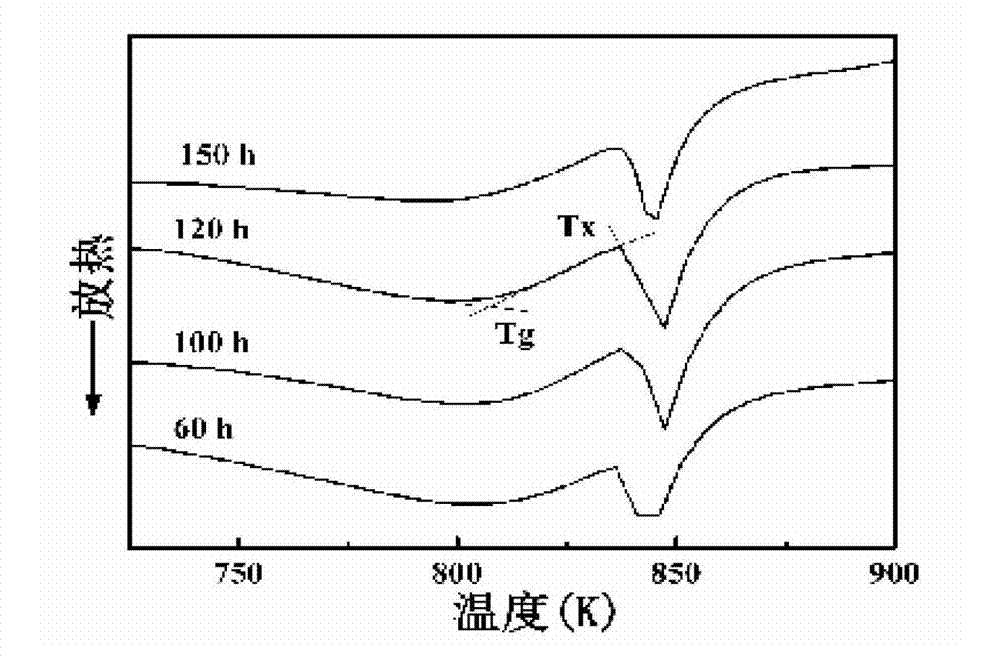

Image

Examples

Embodiment 1

[0029] Step 1: mix powder

[0030] Mix iron powder, copper oxide powder, iron phosphorus powder, carbon powder, and boron powder according to the following atomic percentages: Fe 77at.%, Cu 4at.%, P 9at.%, C 6at.%, B 1at .%, O 3at.%, and contain inevitably introduced trace impurities. Iron, carbon, and boron are all added in the form of simple substances, phosphorus is added in the form of phosphorus-iron compounds, and copper and oxygen are added in the form of copper oxide compounds. Among them, the particle size of iron powder, copper oxide powder, carbon powder, and boron powder is about 48 μm, with a purity of >99.9%, and the particle size of iron phosphorus powder is about 14 μm, with a purity of >99.9%.

[0031] Step 2: Mix the powder

[0032] Put the proportioned iron, copper oxide, phosphorus iron powder, carbon, and boron powder in step 1 into a V-type powder mixer and mix for 10 hours to obtain a nominal composition of Fe 77 Cu 4 P 9 C 6 B 1 o 3 mixed powder...

Embodiment 2

[0036] Step 1: mix powder

[0037] Mix iron, copper oxide, ferrophosphorus powder, carbon, and boron powder according to the following atomic percentages: Fe 75at.%, Cu 4at.%, P 7at.%, C 7at.%, B 3at.%, O 4at.%, and contains trace impurities inevitably introduced. Iron, carbon, and boron are all added in the form of simple substances, phosphorus is added in the form of phosphorus-iron compounds, and copper and oxygen are added in the form of copper oxide compounds. Among them, the particle size of iron powder, copper oxide powder, carbon powder, and boron powder is about 48 μm, with a purity of >99.9%, and the particle size of iron phosphorus powder is about 14 μm, with a purity of >99.9%.

[0038] Step 2: Mix the powder

[0039] Put the proportioned iron, copper oxide, ferrophosphorus powder, carbon, and boron powder in step 1 into a V-type powder mixer and mix for 12 hours to obtain a nominal composition of Fe 75 Cu 4 P 7 C 7 B 3 o 4 mixed powder.

[0040] Step 3: H...

Embodiment 3

[0043] Step 1: mix powder

[0044] Mix iron, copper oxide, ferrophosphorus powder, carbon, and boron powder according to the following atomic percentages: Fe 76at.%, Cu 5at.%, P 8at.%, C 5at.%, B 1at.%, O 5at.%, and contains trace impurities that are inevitably introduced. Iron, carbon, and boron are all added in the form of simple substances, phosphorus is added in the form of phosphorus-iron compounds, and copper and oxygen are added in the form of copper oxide compounds. Among them, the particle size of iron powder, copper oxide powder, carbon powder, and boron powder is about 48 μm, with a purity of >99.9%, and the particle size of iron phosphorus powder is about 14 μm, with a purity of >99.9%.

[0045] Step 2: Mix the powder

[0046] Put the proportioned iron, copper oxide, ferrophosphorus powder, carbon, and boron powder in step 1 into a V-type powder mixer and mix for 16 hours to obtain a nominal composition of Fe 76 Cu 5 P 8 C 5 B 1 o 5 Mix powder.

[0047] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com