Method for removing arsenic by loading titanium dioxide with activated carbon fiber hydrothermal method by means of photoelectrocatalysis oxidation

A technology of activated carbon fiber and titanium dioxide, which is applied in chemical instruments and methods, physical/chemical process catalysts, oxidized water/sewage treatment, etc., can solve the problems of ineffective removal of trivalent arsenic and high cost of arsenic removal, and achieve the benefit of large-scale Large-scale promotion, convenient operation and management, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

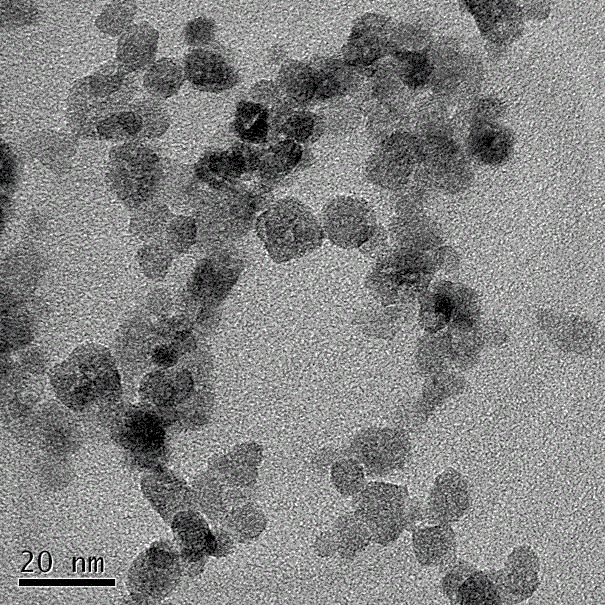

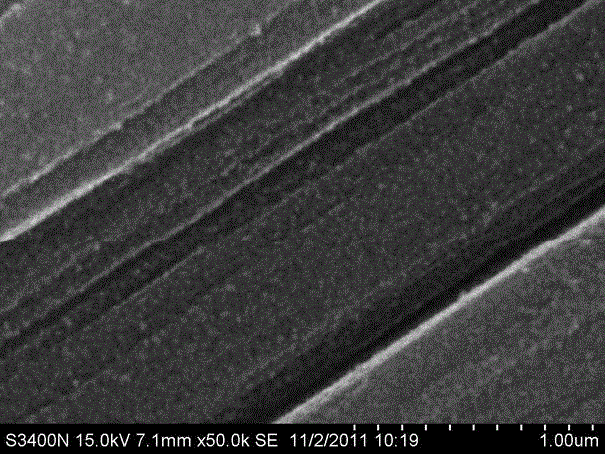

[0031] Weigh 10g of tetrabutyl titanate into an Erlenmeyer flask, add 45mL of absolute ethanol and 20mL of glacial acetic acid in sequence, stir magnetically for 30min, and call it A solution. Add 25mL of absolute ethanol, 6.5mL of twice distilled water and 5mL of glacial acetic acid into another Erlenmeyer flask, stir for 30min with magnetic force, and call it B solution. Use a separatory funnel to drop liquid B into liquid A under magnetic stirring at a rate of 1 drop / second, control the stirring speed to 300 r / min, and continue stirring for 3 hours after the dropping is completed.

[0032] Measure more than 60mL of the solution and activated carbon fibers and place them in a polytetrafluoroethylene-lined high-pressure reactor (effective volume 100mL, pressure 10MPa, filling degree 60%), and react in an oven at 180°C for 3 hours to prepare titanium dioxide-loaded activated carbon fibers. After ultrasonic cleaning for 5 minutes, dry at 105°C for 12 hours.

Embodiment 2

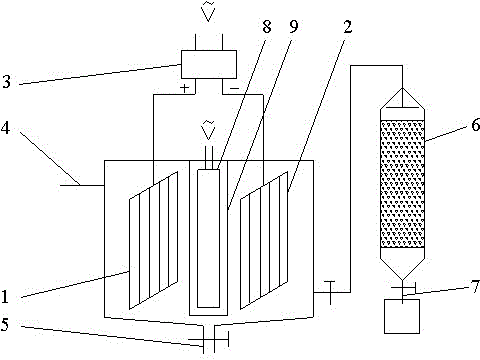

[0034] use as image 3 For the reactor shown, add 250mL of 2mg / L arsenic solution into the reactor, adjust the pH=7, add sodium sulfate to adjust the conductivity to 158 μs / cm, place a UV lamp with a power of 9W inside the reactor, and load 0.25g The titanium dioxide activated carbon fiber was placed inside the reactor as the anode, the activated carbon fiber was used as the cathode, and a cell pressure of 0.5V was applied. After adding the loaded titanium dioxide activated carbon fiber, it was placed in the dark for 3 hours to reach adsorption equilibrium, and the ultraviolet light was irradiated for 20 minutes. The adsorbent is 0.25g titanium dioxide powder.

[0035] The removal rate of the trivalent arsenic solution treated by single applied voltage electrosorption and photocatalytic oxidation is 6.7% and 66.7% respectively. Better oxidation removal effect.

Embodiment 3

[0037] use as image 3 For the reactor shown, add 250mL of 0.25mg / L arsenic solution into the reactor, adjust the pH=7, add sodium sulfate to adjust the conductivity to 158 μs / cm, place a UV lamp with a power of 100W inside the reactor, 0.25g Activated carbon fibers loaded with titanium dioxide are placed inside the reactor as anodes, activated carbon fibers are used as cathodes, and a tank pressure of 1V is applied. After adding activated carbon fibers loaded with titanium dioxide, they are placed in the dark for 3 hours to reach adsorption equilibrium, and the ultraviolet light is illuminated for 60 minutes. The adsorbent is 0.03g active. Aluminum oxide powder.

[0038] The trivalent arsenic solution treated by single applied voltage electrosorption and photocatalytic oxidation was determined to have a removal rate of 6.7% and 91.3%, respectively, and the trivalent arsenic solution treated under the above conditions was determined to have a removal rate of 99.7%, and the ars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com