Marine culture water compound cyclic purification system

A technology of mariculture and combined circulation, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as pollution sources, artificial wetland system blockage, and low water purification efficiency. To achieve the effect of increasing the dissolved oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] According to the amount of water in the mariculture pond and the breeding density, set the appropriate daily circulation ratio r, and calculate the circulation treatment water volume, and the circulation treatment water volume is calculated by r × the water volume of the culture pond (M); for the usual culture pond, the daily circulation ratio r can be set 20%~40%d -1 .

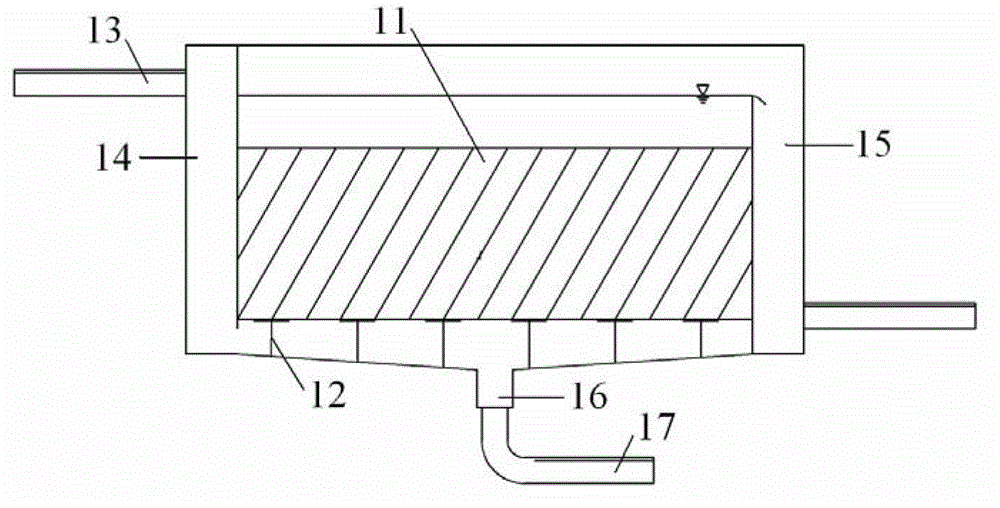

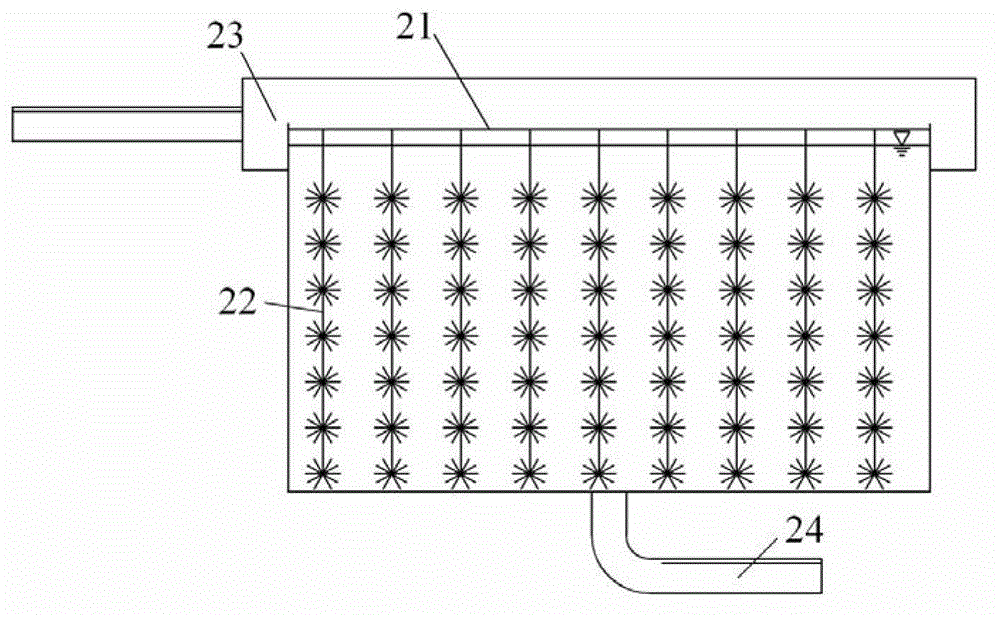

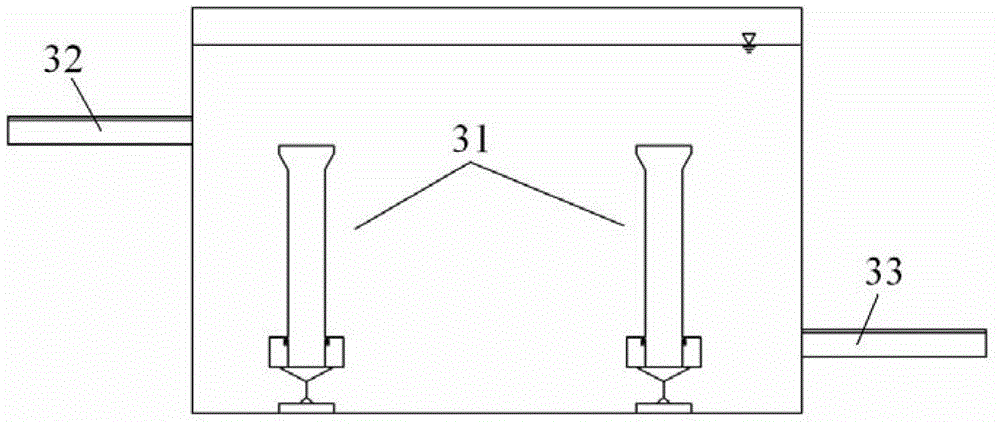

[0045] The main functional units of this system are primary sedimentation unit 1, contact oxidation unit 2, shellfish ecological pond unit 3, and push flow constructed wetland unit 4. Calculate the area of each unit according to the formula: area (S) = flow rate (V) × residence time (T) ÷ depth (H), and then calculate the length and width of each unit according to the appropriate aspect ratio (L:B). Among them, the aspect ratio of primary precipitation unit 1 is 1:2~2:1, the water depth is 1~1.5m, and the residence time is 1~2h; the aspect ratio of contact oxidation unit is 1:1~3:1, the water depth ...

Embodiment 2

[0051] This embodiment is aimed at an area of 1000m 2 , the Penaeus vannamei culture pond with a water depth of 1.6m, the circulation ratio is 20% per day, that is, the treated water volume is 13.33m 3 / h. Reinforced concrete pipes with a diameter of 300mm are used to connect each processing unit. The construction of each processing unit is as follows:

[0052] Primary sedimentation unit: depth 1.8m, water depth 1.5m, length 3m, width 6m, residence time 2h. The front and back ends are respectively provided with 0.3m long inlet and outlet weirs, the bottom of the inlet weir is connected with the sedimentation unit, and the top of the outlet weir is connected with the sedimentation unit. Set up 7×13 supports at an interval of 0.5m in the primary precipitation unit, and the supports are iron discs with a diameter of 0.4m welded on iron steel pipes and a height of 0.2m, and the surface is painted with anti-rust paint. Place a sedimentation inclined tube above the support. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com