Metronidazole preparation method

A technology for metronidazole and nitroimidazole, applied in the field of preparation of metronidazole, can solve problems such as high cost and low yield, and achieve the effects of promoting reaction, reducing production cost and saving usage amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

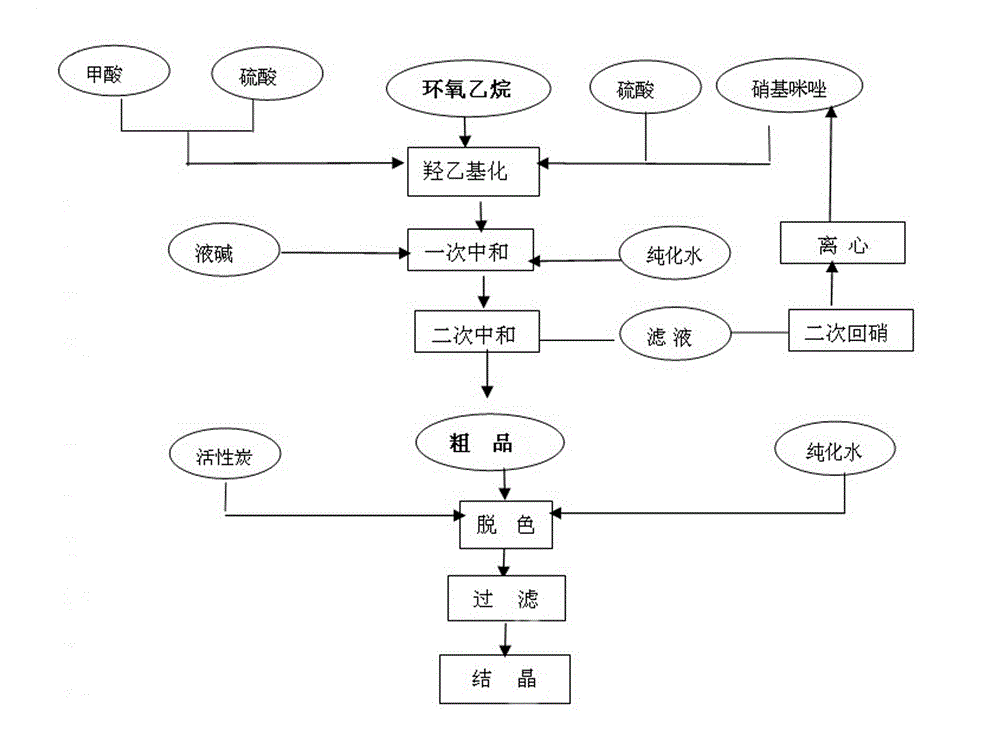

Method used

Image

Examples

Embodiment 1

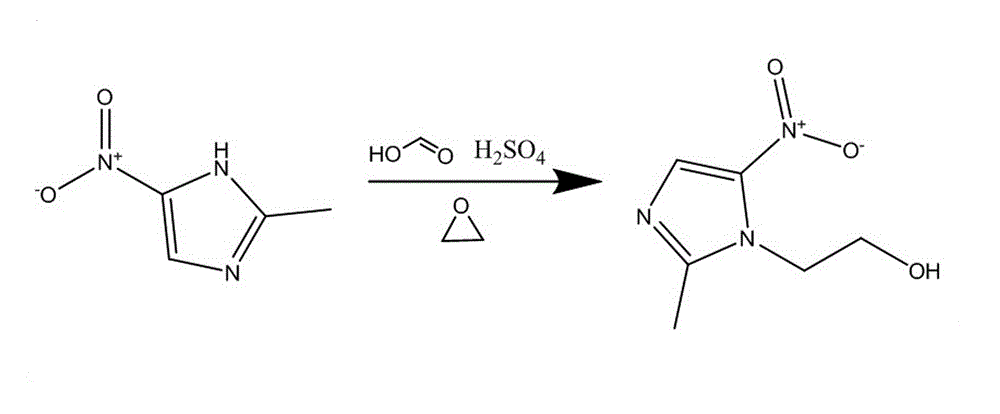

[0034] A method for preparing metronidazole includes the following steps:

[0035] (1) Mixed acid: Put 100 parts of formic acid with a concentration of 97% (1kg per part, the same applies for the following) into the reaction kettle, add 30 parts of concentrated sulfuric acid to prepare mixed acid for use;

[0036] (2) Synthesis reaction: Put 120 parts of the reaction material 2-methyl-5-nitroimidazole into the reaction tank, add the mixed acid prepared in step (1), control the temperature at 75℃, and wait until 2-methyl-5 -After the nitroimidazole is completely dissolved, keep it for 15 minutes, add 98 parts of ethylene oxide and 8 parts of concentrated sulfuric acid, and generate hydroxylation liquid after the reaction;

[0037] (3) One-time neutralization: Put the hydroxylation solution prepared in step (2) back into the nitrate tank, control the temperature at 28°C, add sodium hydroxide (NaOH) dropwise to neutralize to a pH of 2.0, and then lower the temperature to 15 Perform cry...

Embodiment 2

[0042] A method for preparing metronidazole includes the following steps:

[0043] (1) Mixed acid: Put 100 parts of formic acid with a concentration of 95% (10kg per part, the same below) into the reactor, control the temperature at 20~25℃ and add 27 parts of concentrated sulfuric acid to prepare mixed acid for later use; The main purpose of controlling the temperature between 20~25℃ in concentrated sulfuric acid is to prevent the splash of concentrated sulfuric acid from hurting people when preparing mixed acid;

[0044] (2) Synthesis reaction: Put 115 parts of reaction material 2-methyl-5-nitroimidazole into the reaction tank, add the mixed acid prepared in step (1), control the temperature at 80℃, and wait until 2-methyl-5 -After the nitroimidazole is completely dissolved, keep it for 10 minutes, add 95 parts of ethylene oxide and 7 parts of concentrated sulfuric acid, and generate hydroxylation liquid after the reaction;

[0045] (3) One-time neutralization: Put the hydroxylatio...

Embodiment 3

[0050] A method for preparing metronidazole includes the following steps:

[0051] (1) Mixed acid: Put 100 parts of formic acid with a concentration of 98% (5kg per part, the same applies below) into the reactor, control the temperature between 20 and 25 ℃ and add 25 parts of concentrated sulfuric acid to prepare mixed acid for use;

[0052] (2) Synthesis reaction: Put 110 parts of the reaction material 2-methyl-5-nitroimidazole into the reaction tank, add the mixed acid prepared in step (1), control the temperature at 76°C, wait until 2-methyl-5 -Nitroimidazole is completely dissolved and kept for 17 minutes, 100 parts of ethylene oxide and 8.5 parts of concentrated sulfuric acid are added, and a hydroxylation liquid is generated after the reaction; among them, ethylene oxide is added to the reaction tank in four times and concentrated sulfuric acid in three times , Specifically: add ethylene oxide uniformly for the first time within 40 minutes, add concentrated sulfuric acid for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com