Transparent polyimide and preparation method thereof

A polyimide resin, polyamic acid technology, applied in the direction of organic chemistry, etc., can solve the problems of inability to large-scale application, hinder the conjugation of electron clouds, high price, etc., achieve low cost, improve transparent performance, transparency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

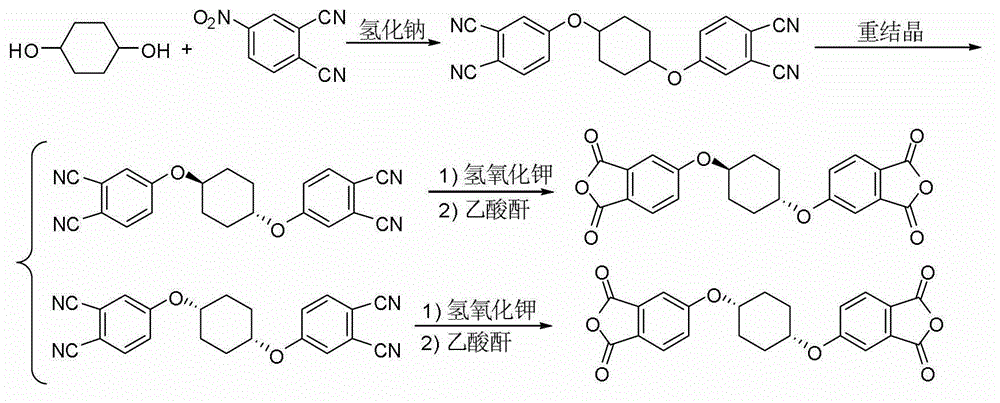

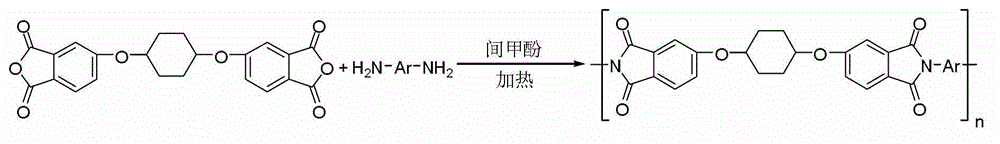

[0057] Embodiment 1: the preparation of 1,4-bis(3,4-dicarboxylic acid phenoxy group) cyclohexane dianhydride:

[0058] Under nitrogen protection, add 9.2g (60% solid content, mass percent, 230mmol) of sodium hydride into a 500mL three-necked flask, then add 100mL of N,N-dimethylformamide, and stir at room temperature for 2 hours. Then dropwise add 11.6g (100mmol) of 1,4-cyclohexanediol cis-trans mixture and 100mL of N, N-dimethylformamide mixed solution, after stirring at room temperature for 1 hour, add 36.4g (210mmol) of The mixed solution of 4-nitrophthalonitrile and 100mL of N,N-dimethylformamide was stirred at room temperature for 24 hours, the reaction solution was poured into water, a precipitate was precipitated, filtered, washed with ethanol, and dried to obtain cis Crude product of back-mixed 1,4-bis(3,4-dicyanophenoxy)cyclohexane.

[0059] The above-mentioned crude product was heated to reflux in 200mL of acetonitrile solution, filtered, and dried to obtain 19.3 g ...

Embodiment 2

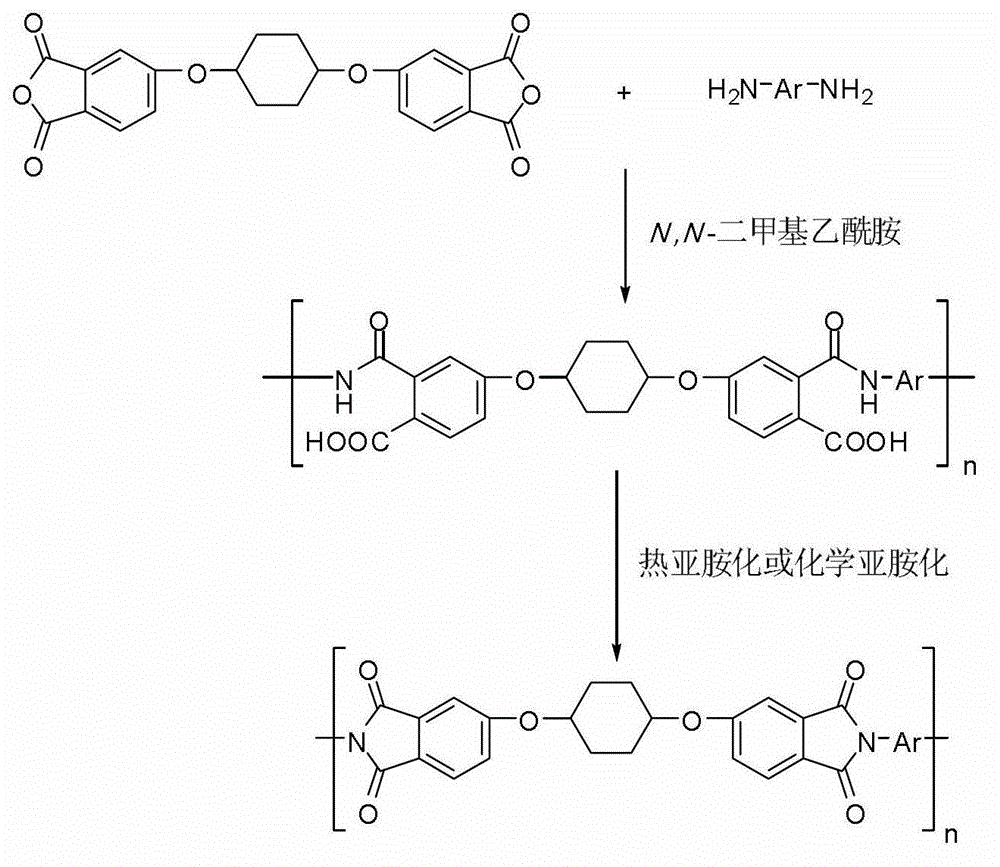

[0066] In this embodiment, the transparent polyimide resin material has the following structural formula:

[0067]

[0068] The specific preparation method is: under the protection of nitrogen, mix 1.2481g (4.0mmol) of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl and 16ml of N,N-dimethylethane Add the amide into a 50mL reaction flask, stir at room temperature, and after 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl is completely dissolved, add 1.6343g (4.0mmol) of trans 1, 4-bis(3,4-dicarboxylic acid phenoxy group) cyclohexane dianhydride, continued to stir at room temperature for 24 hours to obtain a viscous polyamic acid solution, and then the solution was diluted to a concentration of 10% by weight ( Based on the sum of the mass of raw material dianhydride and diamine, the same below).

[0069]The diluted polyamic acid solution is uniformly coated on a clean glass plate, the thickness of the solution coating film is 0.5mm, the glass plate is placed in a drying oven, ...

Embodiment 3

[0072] In this embodiment, the transparent polyimide resin material has the following structural formula:

[0073]

[0074] The specific preparation method is: under the protection of nitrogen, mix 1.2483g (4.0mmol) of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl and 16ml of N,N-dimethylethane Add the amide into a 50mL reaction flask, stir at room temperature, and then add 1.6351g (4.0mmol) of cis-1 after the 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl is completely dissolved. 4-bis(3,4-dicarboxylic acid phenoxy)cyclohexanedianhydride was stirred at room temperature for 24 hours to obtain a viscous polyamic acid solution, and then the solution was diluted to a concentration of 10% by weight.

[0075] The diluted polyamic acid solution is uniformly coated on a clean glass plate, the thickness of the solution coating film is 0.5mm, the glass plate is placed in a drying oven, and the temperature is raised according to the following procedure: 80°C, 1 hour; 150°C , 1 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com