Temporary plugging agent for drilling fluid and preparation method of temporary plugging agent

A drilling fluid and temporary plugging agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance of temporary plugging agents, limited plugging effect, unfavorable reservoir protection, etc., and achieve easy acidification The effect of removing plugging, improving production capacity and protecting reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

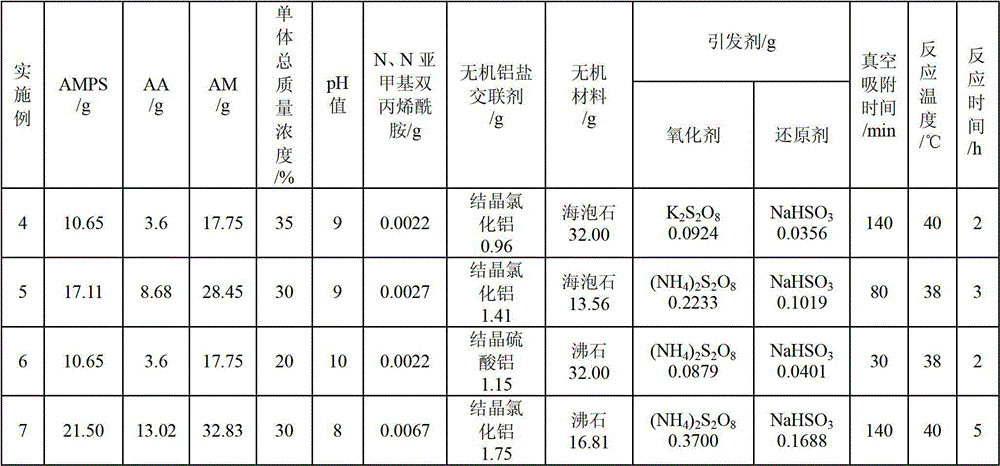

Examples

Embodiment 1

[0019] Mix 17.11g of 2-acrylamide-2-methylpropanesulfonic acid, 8.68g of acrylic acid, and 28.45g of acrylamide to form reaction mixture A, completely dissolve in water, adjust the pH value to 9.0 with sodium hydroxide solution, and prepare the total mass concentration 30% reaction mixture aqueous solution B; then add 3ml aqueous solution containing 0.0027g N,N-methylenebisacrylamide and 5ml aqueous solution containing 1.95g crystalline aluminum chloride, stir to dissolve and then add 13.56g treated seawater Paoolite solid powder, and then adjust the pH value to 9.0 with sodium hydroxide solution to obtain a stable white suspension; after 30min vacuum adsorption process, mix evenly, white suspension, 5ml 0.2349g potassium persulfate aqueous solution and 3ml 0.0905 Put the aqueous solution of sodium bisulfite together in a water bath to raise the temperature to 38°C, and then initiate polymerization under slow stirring. After 3 hours of reaction, the resulting product is cut int...

Embodiment 2

[0021] Mix 17.11g of 2-acrylamide-2-methylpropanesulfonic acid, 8.68g of acrylic acid, and 28.45g of acrylamide to form reaction mixture A, completely dissolve in water, adjust the pH value to 8.0 with sodium hydroxide solution, and prepare the total mass concentration 30% reaction mixture aqueous solution B; then add 3ml aqueous solution containing 0.0027g N, N-methylenebisacrylamide and 5ml aqueous solution containing 1.95g crystalline aluminum chloride respectively, stir to dissolve and then add 5.42g treated seawater Paoolite solid powder, and then adjust the pH value to 8.0 with sodium hydroxide solution to obtain a stable white suspension; after 80min vacuum adsorption process, mix evenly, white suspension, 5ml 0.2349g potassium persulfate aqueous solution and 3ml 0.0905 Put the aqueous solution of sodium bisulfite together in a water bath to raise the temperature to 38°C, and then initiate polymerization under slow stirring. After 3 hours of reaction, the resulting produ...

Embodiment 3

[0023] Mix 21.50g of 2-acrylamide-2-methylpropanesulfonic acid, 13.02g of acrylic acid, and 32.83g of acrylamide to form reaction mixture A, completely dissolve in water, adjust the pH value to 10.0 with sodium hydroxide solution, and prepare the total mass concentration 20% reaction mixture aqueous solution B; then add 3ml aqueous solution containing 0.0034g N, N-methylenebisacrylamide and 5ml aqueous solution containing 2.42g crystalline aluminum sulfate, stir and dissolve, then add 6.73g treated zeolite solid powder, and then adjust the pH value to 10.0 with sodium hydroxide solution to obtain a stable white suspension; after 30min vacuum adsorption process, mix evenly, mix the white suspension, 5ml 0.3890g potassium persulfate aqueous solution and 3ml 0.1498g sulfurous acid The sodium hydrogen aqueous solution is placed together in a water bath and the temperature is raised to 50°C, and then the polymerization is initiated under slow stirring. After 5 hours of reaction, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com