Preparation method for oxidized regenerated cellulose hemostatic material with surface nanostructure

A technology of regenerated cellulose and nanostructures, applied in fiber processing, medical science, absorbent pads, etc., can solve the problems of single hemostatic mechanism, slow hemostatic speed, and small specific surface area of oxidized cellulose hemostatic materials, so as to benefit platelets Adhesion, excellent blood absorption, shortening the effect of hemostasis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

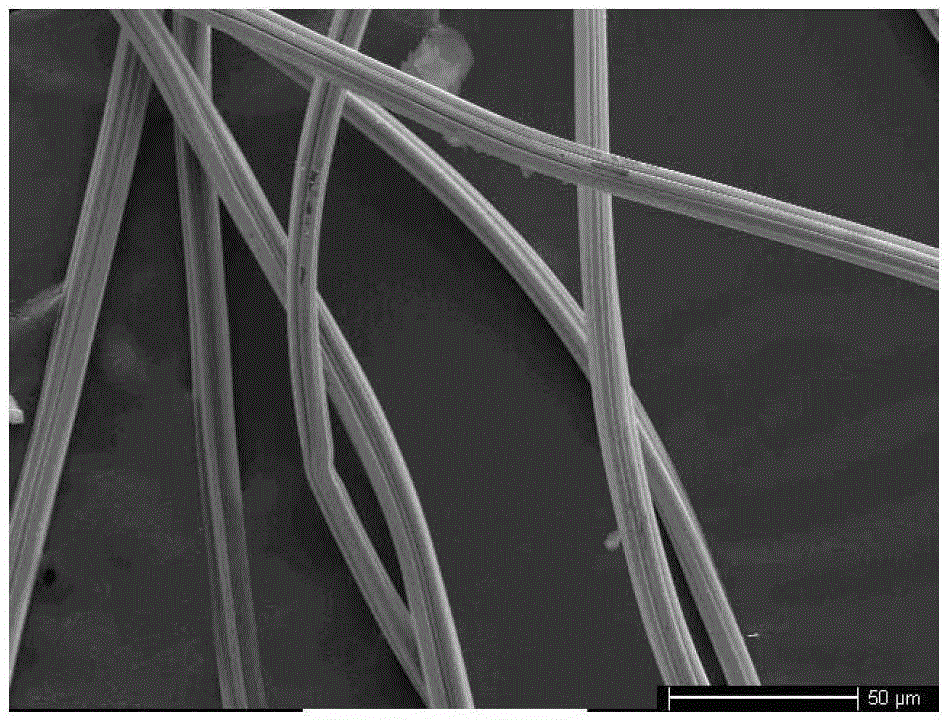

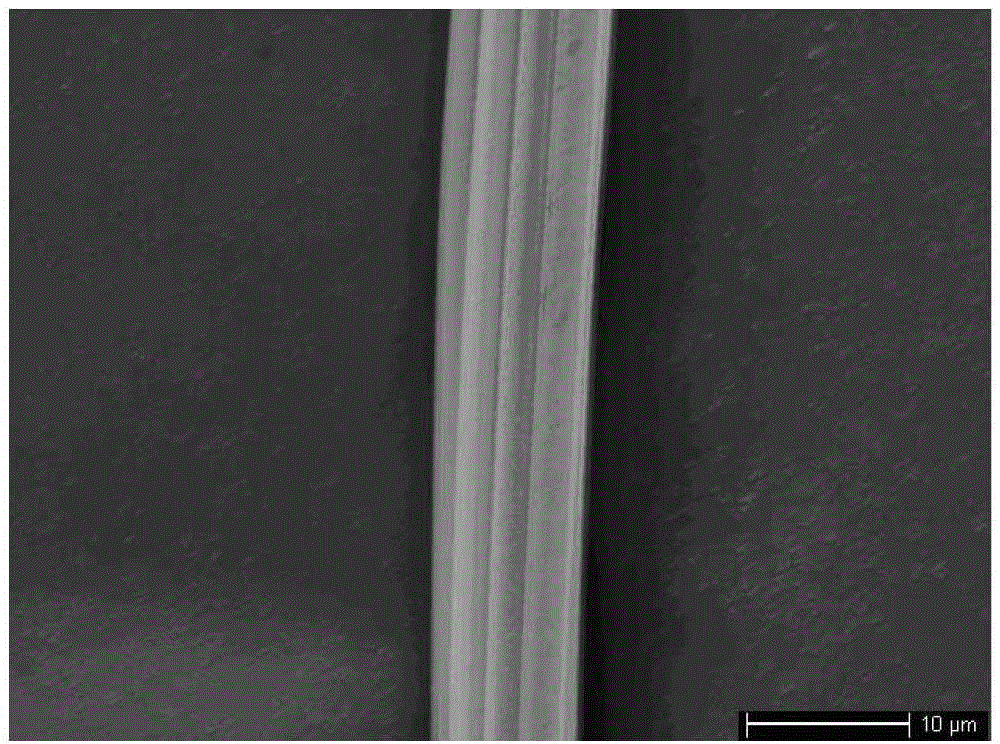

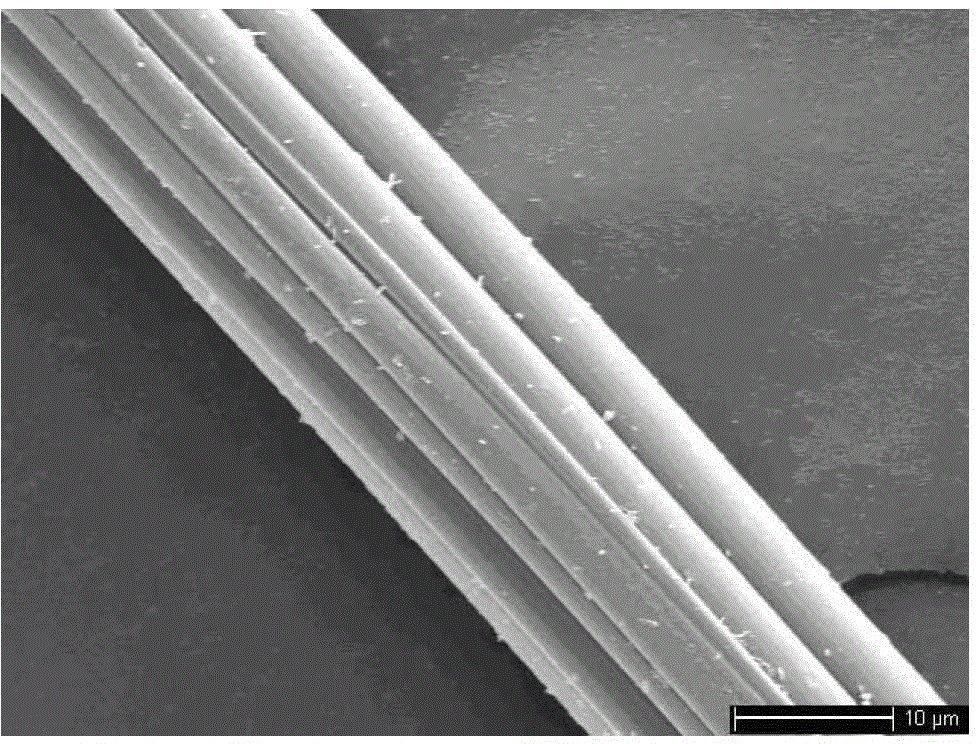

[0022] Embodiment 1: A method for preparing an oxidized regenerated cellulose-based hemostatic material with a surface layer nanostructure according to this embodiment is implemented in the following steps:

[0023] 1. Prepare the collagen aqueous solution and store it sealed at 0-4°C;

[0024] Two, take wood pulp viscose long fiber as raw material, adopt knitting machine to prepare viscose fiber gauze; Wherein, described knitting machine width 8~18m, traction belt spacing 4.2~6.2m, traction belt width 4.2~6.2m, traction Speed 180~360r / m, mesh width 0.5~2.5mm;

[0025] 3. Oxidize the viscose staple fiber and the viscose fiber gauze made in step 2 by using an oxidizing agent solution, and the oxidized product is subjected to cyclohexane, 50% to 70% ethanol aqueous solution and absolute ethanol respectively. Washing, and then vacuum freeze-drying at -20 to -55°C for 24 to 72 hours to obtain oxidized viscose staple fibers and oxidized viscose fiber gauze, which are sealed and ...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass fraction of collagen in the collagen aqueous solution in step 1 is 0.8-1.5%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reaction temperature in the oxidation reaction process in step 3 is maintained at 18-19.5° C., and the stirring reaction is continued for 24-56 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com