SiO2-containing denitration catalyst and preparation method thereof

A denitration catalyst and material preparation technology, which is applied in the field of denitration catalysts, can solve the problems of huge influence on SCR catalyst performance and high catalyst cost, achieve good chemical stability and thermal stability, reasonable preparation process design, and improve crystal transformation temperature and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

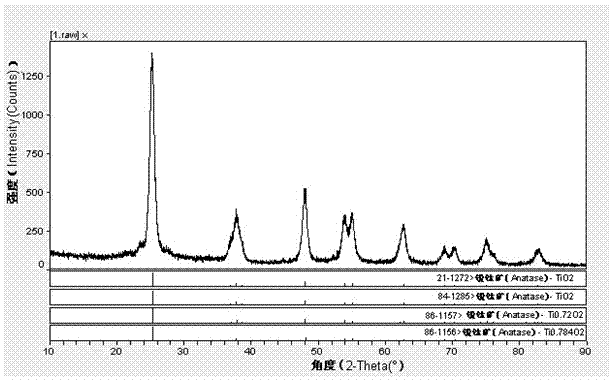

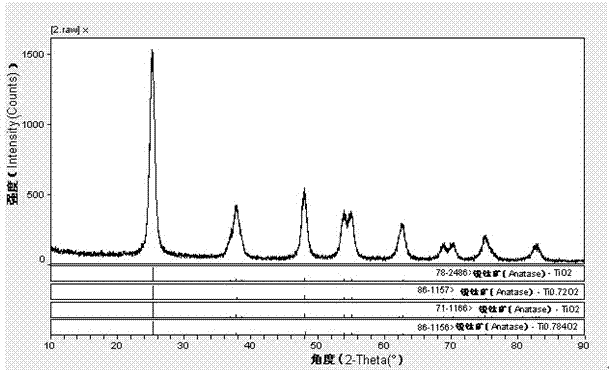

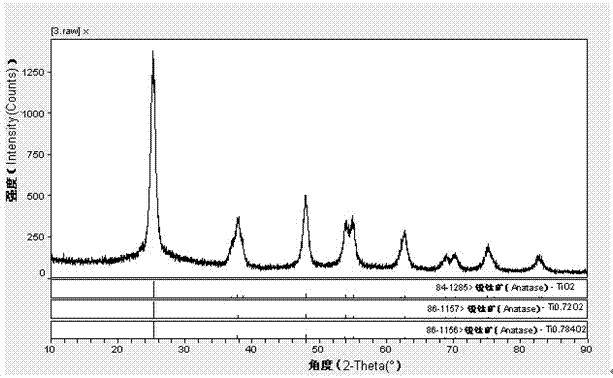

Image

Examples

specific Embodiment

[0032] A kind of added SiO 2 The denitration catalyst, the mass percentage of each component in the denitration catalyst is as follows: V 2 o 5 1%~2%, WO 3 5%, SiO 2 5%~10%, the rest is TiO 2 . Specific examples are as follows:

[0033] (1) Examples 1-5 contain SiO for flue gas denitrification 2 The denitration catalyst, the mass percentage of each component in the denitration catalyst is as follows.

[0034] Example V 2 o 5 WO 3 SiO 2 TiO 2 Example 1 1 5 0 94 Example 2 1 5 5 89 Example 3 1 5 10 84 Example 4 1 5 20 74 Example 5 1 5 30 64

Embodiment 1

[0036] (1) Weigh 60g of titanium sulfate (Ti(SO 4 ) 2 ) was dissolved in a water bath at a temperature of 60°C, then dripped with ammonia water and stirred to dissolve, the pH value of the dissolved solution ranged from 10 to 11, and the resulting suspension was left to stand for 10 hours at a temperature of 40°C, filtered and washed. The obtained solid was dried at a temperature of 110°C for 10 hours, and finally placed in a muffle furnace for calcination at a temperature of 500°C for 2 hours, and finally cooled and then ground and sieved into 200 meshes.

[0037] (2) Weigh 0.274g of ammonium metavanadate and 1.131g of ammonium metatungstate, add a certain amount of oxalic acid, and stir in a water bath at a temperature of 60°C to fully dissolve the prepared TiO 2 -SiO 2 Immerse in the water bath solution, fully dissolve and stir evenly. Then the prepared solution was dried at 110° C. for 12 hours.

[0038] Oxalic acid (content≧99.5) is used as a cosolvent, and the dosage...

Embodiment 2

[0043] (1) Weigh 60g of titanium sulfate (Ti(SO 4 ) 2 ) was dissolved in a water bath at a temperature of 60°C. Add 4g of silica sol with a mass fraction of 25% and stir to mix evenly. Then add ammonia water and stir to dissolve. The pH value of the dissolved solution ranges from 10 to 11. Stand still at 40°C for 10 hours, filter and wash, and dry the obtained solid at 110°C for 10 hours, and finally place it in a muffle furnace and roast at 500°C for 2 hours, and finally grind it after cooling , and sieve into 200 mesh to get TiO 2 -SiO 2 Composite carrier.

[0044] (2) Weigh 0.287g ammonium metavanadate and 1.187g ammonium metatungstate, add a certain amount of oxalic acid, stir in a water bath at a temperature of 60°C to fully dissolve, and prepare the TiO 2 -SiO 2 Immerse in the water bath solution, fully dissolve and stir evenly. Then the prepared solution was dried at 110° C. for 12 hours.

[0045] (3) Roasting

[0046] The prepared sample evaporated to dryness w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com