Preparation method for 4-aminoacetophenone

An aminoacetophenone, hydroxyl technology, applied in a new preparation field of p-aminoacetophenone, can solve the problems of harsh reaction conditions, many by-products, strong reagent corrosion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation of N-(4-acetylphenyl)-2-hydroxyl-2-methylpropionamide

[0019] Dissolve 3.00g (22.06mmol) of p-hydroxyacetophenone in 15mL of DMA in a 100mL round bottom flask, add 2.65g (66.18mmol) of sodium hydroxide and stir the reaction at 15-25°C for 1 hour. Subsequently, 11.00 g (66.18 mmol) of 2-bromo-2-methylpropanamide was added and the reaction was stirred at 15-25°C for 5 hours (the product of this step was directly carried to the next step without isolation). After the reaction, 7.94g (198.54mmol) sodium hydroxide was added and stirred at 45-50°C for 1 hour, and finally 30mL of water was added and stirred at room temperature for crystallization. After suction filtration and natural air drying, 2.90 g of yellow crystal powder was obtained with a yield of 59.5%, which can be directly used in the next reaction without further purification.

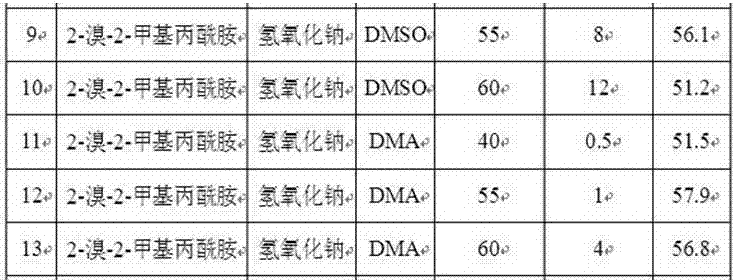

[0020] Similarly, substitute 2-chloro-2-methylpropanamide for 2-bromo-2-methylpropanamide, potassium hydro...

Embodiment 2

[0027] Embodiment 2: the preparation of p-aminoacetophenone

[0028] Dissolve 4.72 g (118.08 mmol) of sodium hydroxide in 13 mL of water in a 100 mL round bottom flask, then add 13 mL of DMA and 2.90 g (13.12 mmol) of N-(4-acetylphenyl)-2-hydroxy- 2-methylpropanamide, and heated to reflux at 90°C for 1 hour. After the reaction was completed, 26 mL of water was added and stirred at room temperature for crystallization. After suction filtration and natural air drying, 1.55 g of yellow crystal powder was obtained with a yield of 87.6% and a total yield of 52.1%.

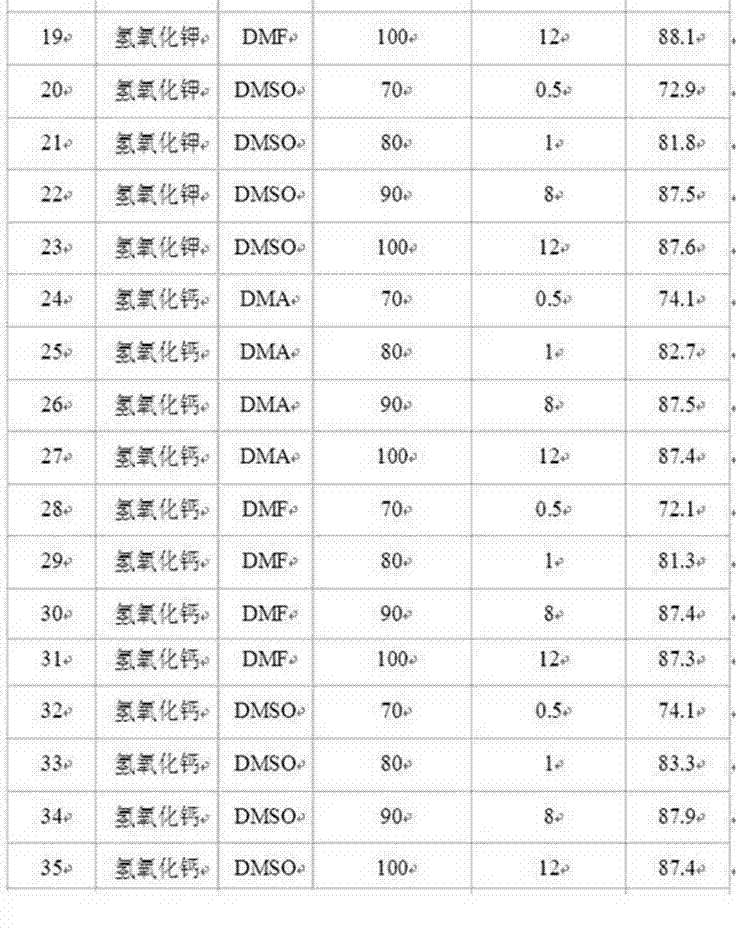

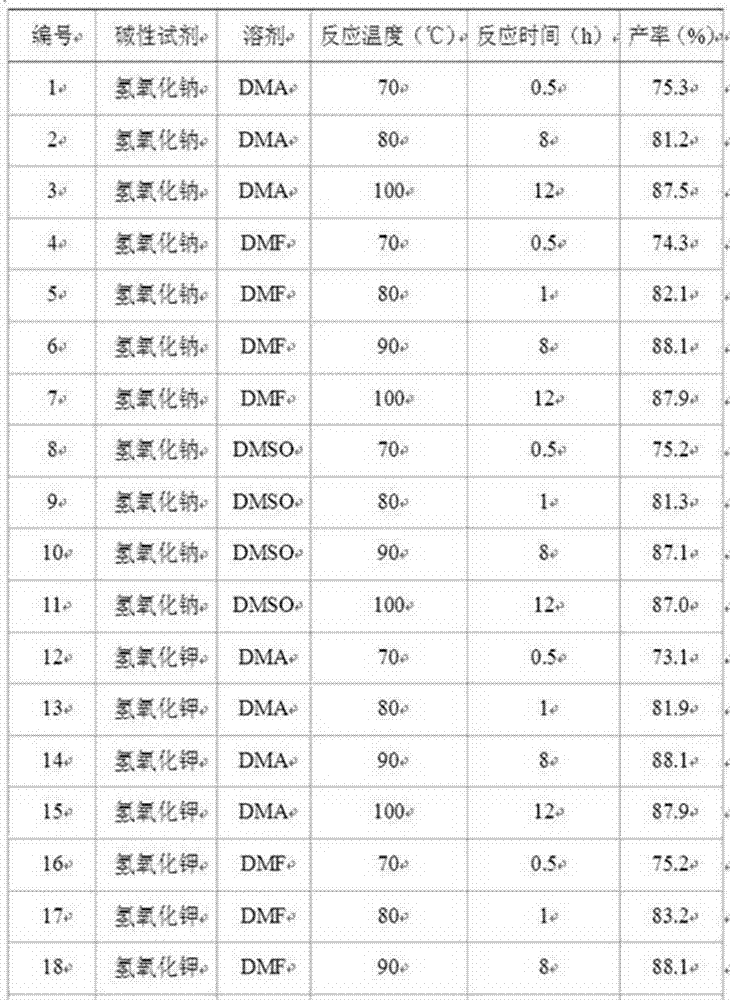

[0029] Similarly, replace sodium hydroxide with potassium hydroxide or calcium hydroxide, and replace N,N-dimethylacetamide (DMA) with N,N-dimethylformamide (DMF) or dimethylsulfoxide (DMSO). ), change the hydrolysis reaction temperature and reaction time to obtain p-aminoacetophenone, and the results are listed in Table 2.

[0030]

[0031] Table 2. Preparation of p-aminoacetophenone

[0032]

[0033]

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com