Method for modifying natural graphite

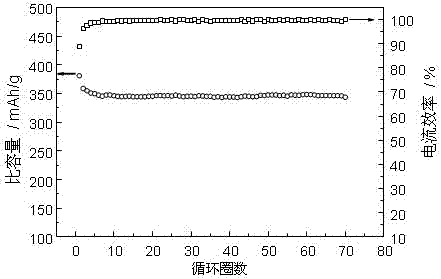

A natural graphite, modified technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of low charge and discharge efficiency and poor cycle performance of natural graphite, achieve improved electrochemical performance, high charge and discharge efficiency, reduce common embedded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

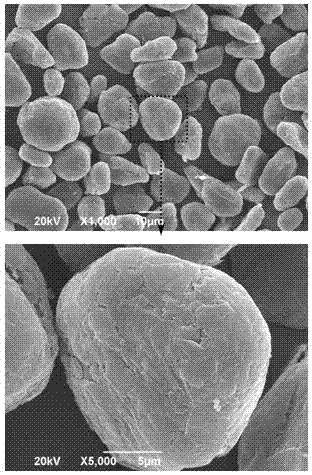

[0036] The modified natural graphite material for lithium-ion batteries in this example uses concentrated sulfuric acid to oxidize spherical natural graphite at 200°C for 10 hours, and then uses thermosetting phenolic resin to modify it. The solvent for dissolving the phenolic resin is Water ethanol, phenolic resin coating amount is 10%.

[0037] The preparation process is as follows: put 100g of spherical natural graphite (particle size D50 is 17.8μm) in a reaction kettle and react with 250ml of concentrated sulfuric acid with a concentration of 98% at 200°C for 10 hours; the reacted natural graphite balls are centrifuged and washed repeatedly, Dry last. Weigh 10 g of thermosetting phenolic resin and add it to ethanol to dissolve; add oxidized natural graphite balls to ethanol dissolved in phenolic resin, stir for 4 hours to make the solution uniform, and let it stand for 1 hour. At 70°C, evaporate the ethanol to dryness and pass through a 300-mesh sieve. Put the sieved gra...

Embodiment 2

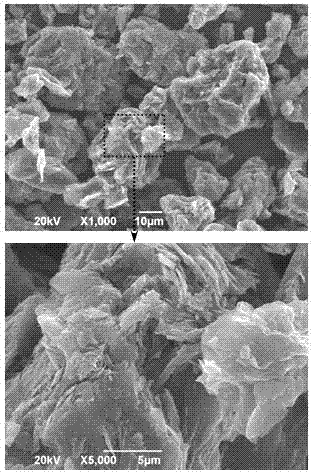

[0043] Put 100g of spherical natural graphite (average particle size of 10μm) in a reaction kettle and react with 200ml of 30% hydrogen peroxide at 50°C for 25 hours; the reacted natural graphite balls are centrifuged repeatedly, rinsed, and finally dried. Weigh 100 g of polystyrene and add it into acetone to dissolve; add the oxidized natural graphite ball into the acetone dissolved in polystyrene, stir for 4 hours to make the solution uniform, and let it stand for 1 hour. At 70°C, evaporate acetone to dryness and pass through a 300-mesh sieve. Put the sieved graphite into the quartz boat, put it into the quartz tube, push the tube furnace, and control the heating rate of the system with the program temperature controller. Access to N 2 As a protective gas to prevent graphite from being oxidized by air, raise the temperature to 100°C at a rate of 5°C / min, keep it for 12 hours, then raise it to 700°C at a rate of 3°C / min, keep it for 24 hours, and keep it at 5°C / min cooling...

Embodiment 3

[0045] Put 100g of spherical natural graphite (average particle size of 30μm) in a reaction kettle and react with ammonium persulfate with a concentration of 1mol / L at 100°C for 15 hours; the reacted natural graphite balls are centrifuged repeatedly, rinsed, and finally dried. Weigh 500g of polyvinyl alcohol and add it into cyclohexane to dissolve; add the oxidized natural graphite ball into cyclohexane dissolved in polyvinyl alcohol, stir for 4h to make the solution uniform, and let it stand for 1h. At 70°C, evaporate the cyclohexane to dryness and pass through a 300-mesh sieve. Put the sieved graphite into the quartz boat, put it into the quartz tube, push the tube furnace, and control the heating rate of the system with the program temperature controller. Access to N 2 As a protective gas to prevent graphite from being oxidized by air, heat up to 600°C at a rate of 30°C / min, hold for 0.2 hours, then raise to 1500°C at a rate of 20°C / min, hold for 1 hour, and heat at 20°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com