Testing liquid for testing pollution resistance of membrane biological reactor (MBR) membrane materials and testing device of testing liquid

A test device and pollution resistance technology, which is applied in the field of test liquid and its test device for the detection of pollution resistance of MBR membrane materials, can solve the problem that the composition of the mixed liquid in MBR membrane pool is not stable enough, which affects the production progress of the membrane material production industry, Problems such as equipment and system occupy a large area to achieve the effect of saving infrastructure costs, shortening the evaluation cycle, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Configure the test solution, the composition is as follows:

[0057] Particles with a particle size of less than 200 meshes (including dry mud particles) 9000mg / L

[0058] Sodium alginate 100mg / L

[0059] Bovine serum albumin 100mg / L

[0060] Sodium humate 50mg / L

[0061] Calcium chloride 550mg / L

[0062] The balance is pure water

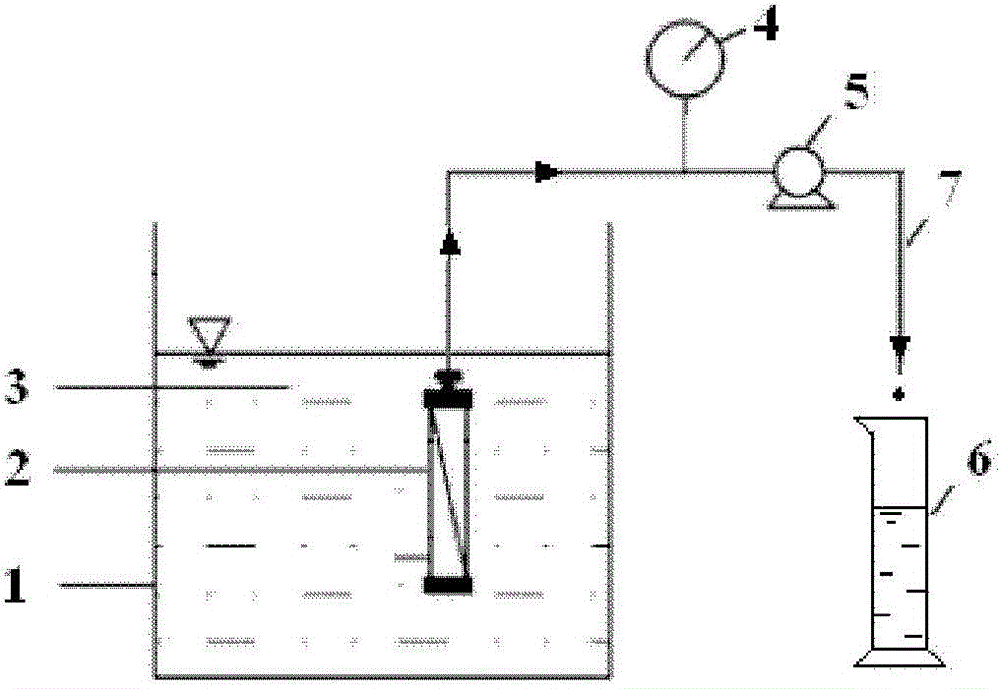

[0063] Such as figure 1 As shown, a set of test equipment is installed, including a test liquid pool 1, a membrane module 2 submerged below the liquid level of the test liquid pool 1, and an outlet pipeline 7 connected to the membrane module 2. The above-mentioned For the test liquid, there is an aeration device in the test liquid pool 1; a flux test device is provided on the membrane module; a pressure gauge 4 and a vacuum pump 5 are provided on the outlet pipeline.

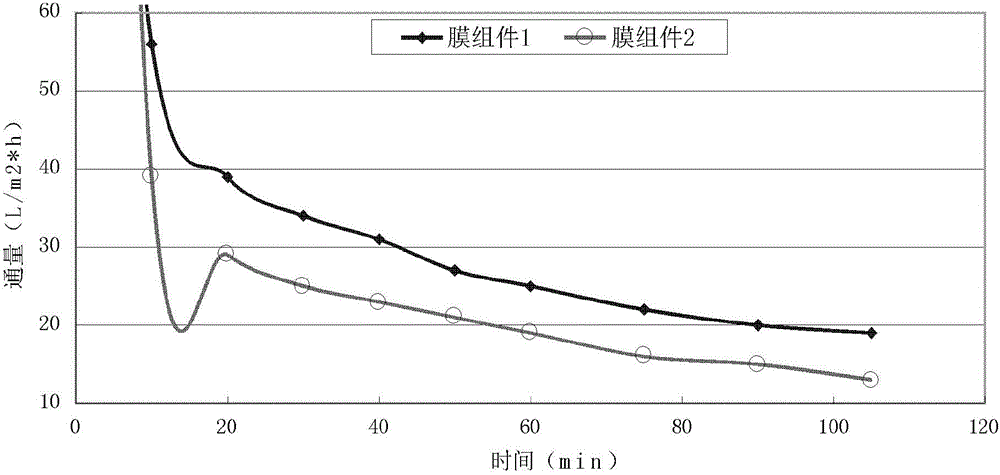

[0064] After fully soaking the sample PVC membrane module (1) and PVC membrane module (2) with an effective length of 30cm in pure water, measure its initial pure water ...

Embodiment 1

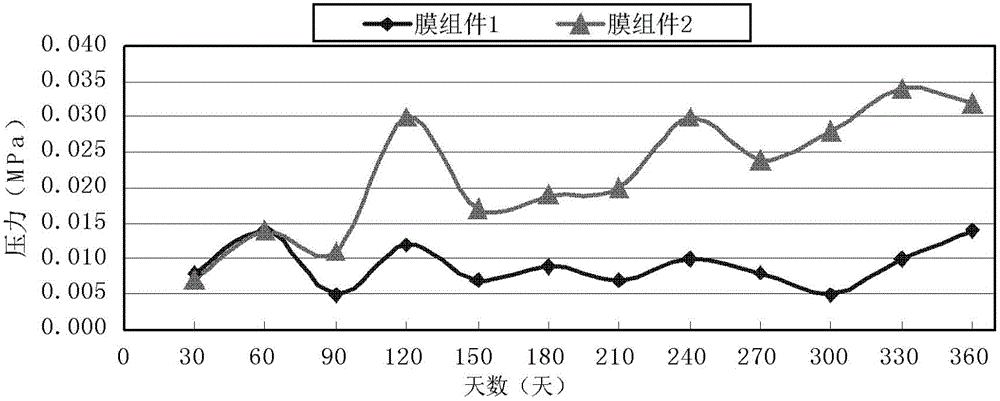

[0069] Take the same test sample PVC membrane module (1) and PVC membrane module (2) and use the traditional method to test the pollution resistance of the samples in the existing pilot test system purchased in the market. The two sets of membrane modules operate for one year under the following conditions: the operating aeration volume is 6.5m 3 / h, the sludge concentration is 6000~8000mg / L, and the average membrane flux is 25L / m 2 h, the water output is 170L / m 2 About h, open for 7 minutes and run for 1 minute intermittently, and clean online once a week. The pollution resistance of the membrane filament is reflected by the pressure change of the two membrane modules under constant flux. Some data in the running cycle such as image 3 and shown in Table 2.

[0070] Table 2

[0071]

[0072] It can be seen that the results of the evaluation of the fouling resistance of the membrane material using the test solution and the test device of this embodiment and the traditi...

Embodiment 2

[0074] Carry out identically with embodiment 1, only have test solution composition difference, concrete composition is as follows:

[0075] Particles with a particle size of less than 200 meshes (including dry mud particles) 1000mg / L

[0076] Starch 150mg / L

[0077] Collagen 200mg / L

[0078] Sodium Fulvic Acid 200mg / L

[0079] Calcium carbonate 500mg / L

[0080] Sodium chloride 500mg / L

[0081] The balance is pure water

[0082] The test results show that the test solution of this embodiment can also effectively evaluate the fouling resistance of membrane materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com