Perfluorinated ion exchange resin and preparation method thereof

A technology for exchanging resin and perfluorinated ions, applied in the field of perfluorinated ion exchange resin and its preparation, to achieve the effects of flexible operation, high mechanical strength and low membrane resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

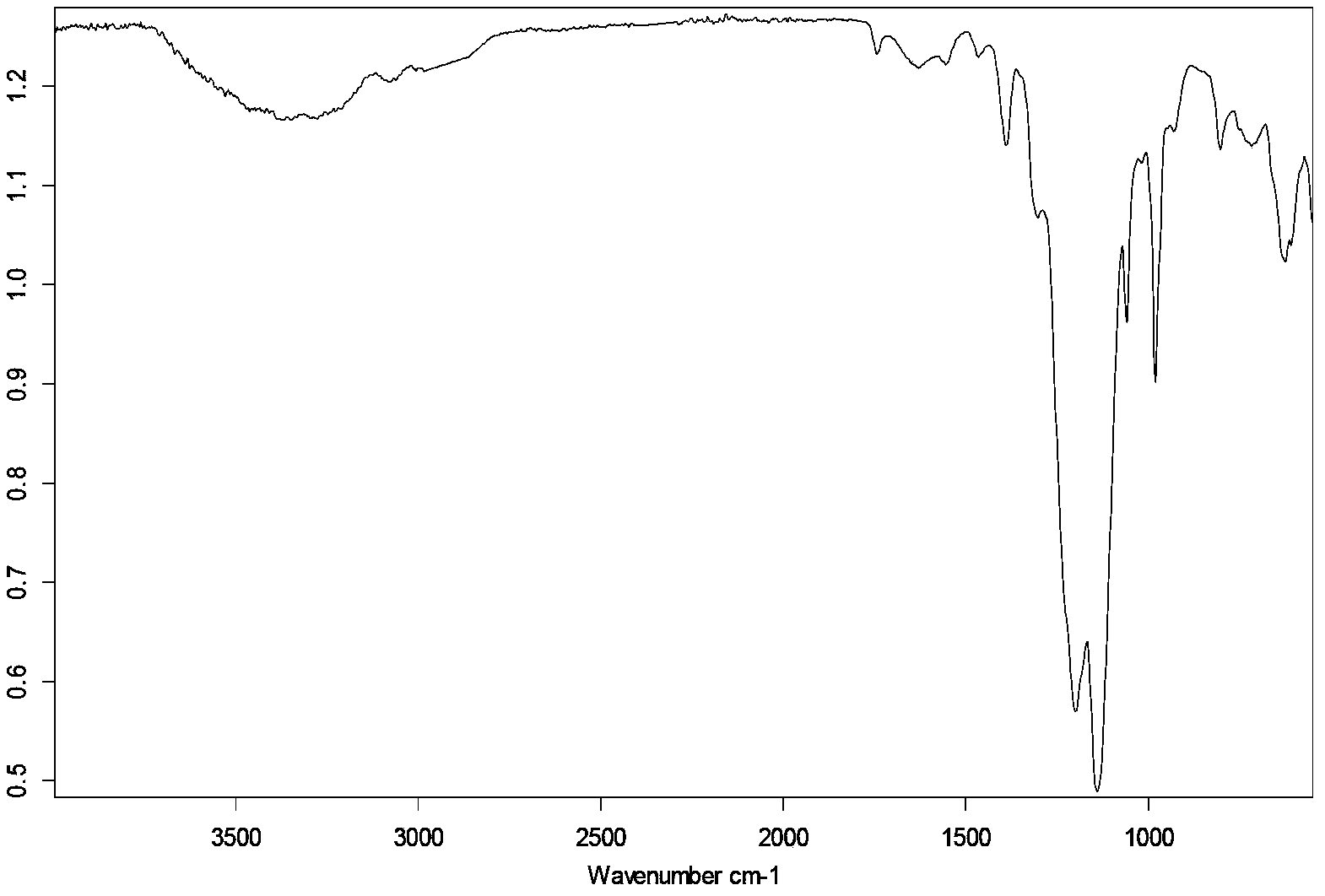

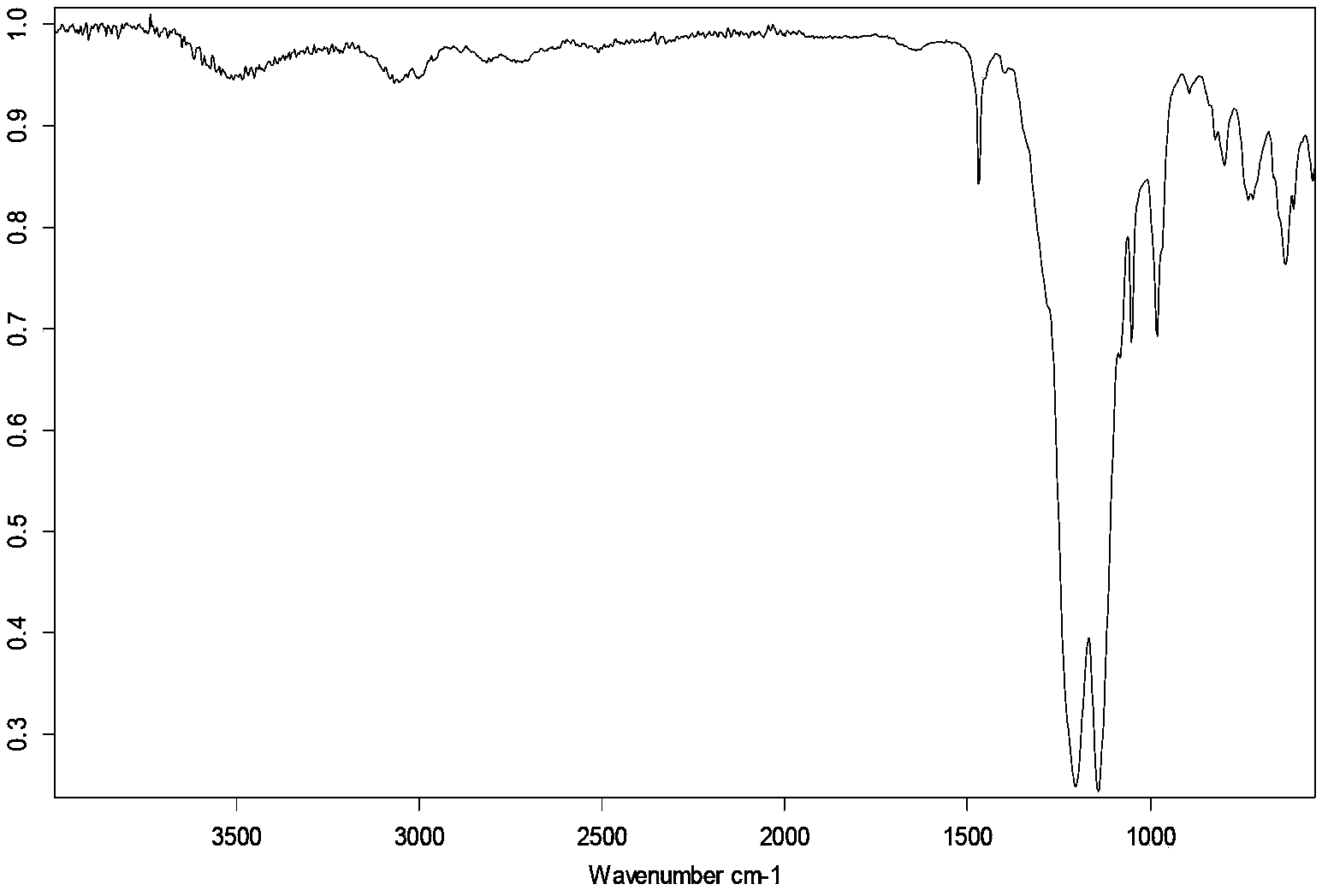

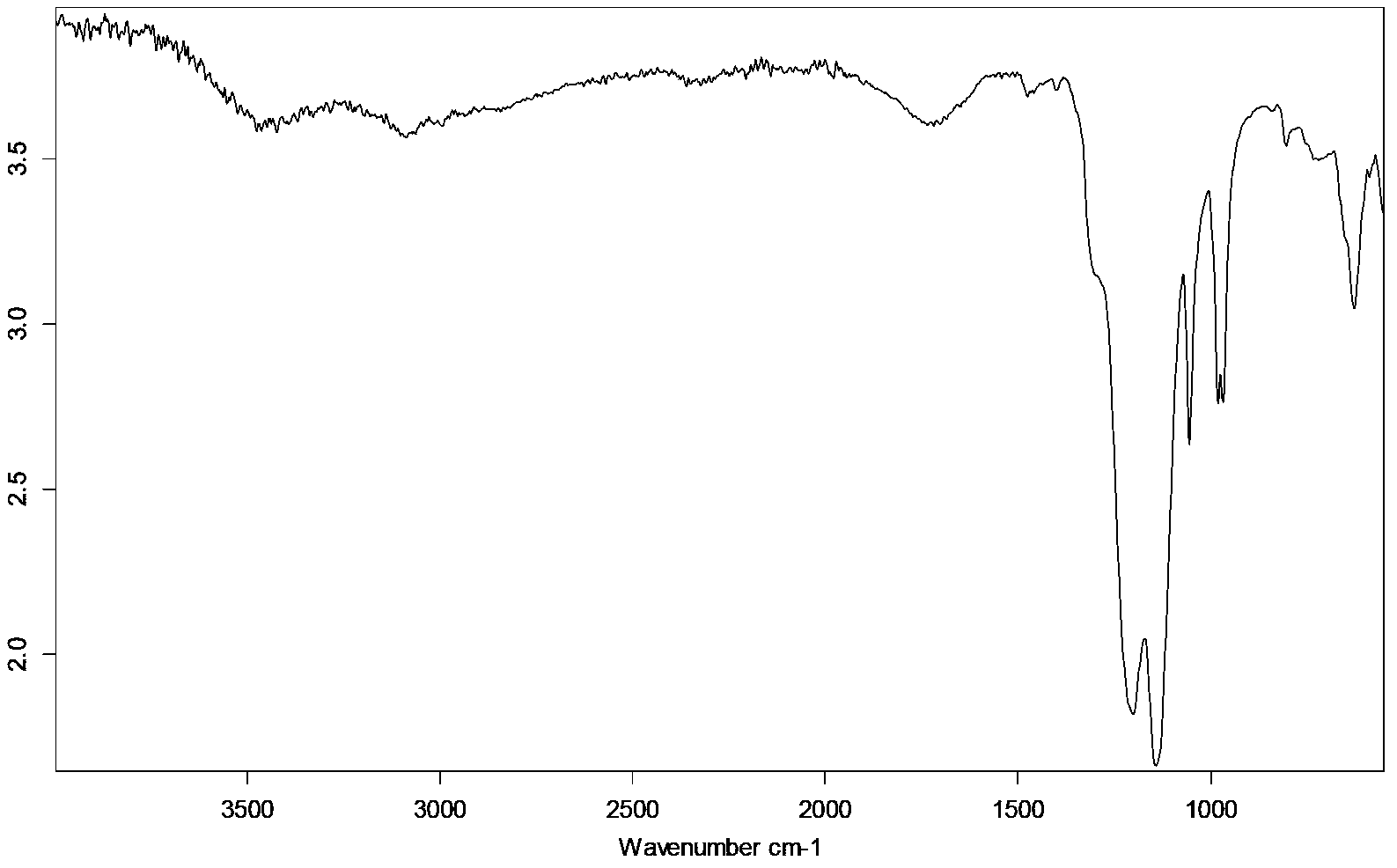

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of preparation method of perfluorinated ion exchange resin, the steps are as follows:

[0038] Prepare precursor resin:

[0039] Wash the 10L reactor and add 6L of deionized water, 100ml of an aqueous solution containing 8g of ammonium perfluorooctanoate, 100ml of a sodium borate solution with a mass concentration of 3%, start the stirring device, and replace it three times. After testing, the oxygen content in the reactor is qualified (less than 5ppm ), vacuumize, and add 500g of sulfonyl fluoride pendant vinyl ether monomer 1 (structural formula: CF 2 =CF-O-CF 2 -CF 2 -SO 2 F) and 500g sulfonyl fluoride pendant vinyl ether monomer 2 (structural formula is: CF 2 =CF-OCF 2 -CF(CF 3 )-O-CF 2 CF 2 SO 2 After F), fill the reaction kettle with tetrafluoroethylene monomer and keep the pressure to 2.3MPa, raise the temperature to 65°C, add 100g of ammonium persulfate aqueous solution (initiator solution) with a mass concentration of 3% with a met...

Embodiment 2

[0046] Embodiment 2: a kind of preparation method of perfluorinated ion exchange resin comprises the following steps:

[0047] Prepare the precursor resin with sulfonyl fluoride side group according to the method of embodiment 1, the difference is: add 600g sulfonyl fluoride monomer 1 (CF 2 =CF-O-CF 2 CF 2 -SO 2 F) and 300 g of sulfonyl fluoride monomer 2 (CF 2 =CF-O-CF 2 CF (CF 3 )-O-CF 2 CF 2 SO 2 F), and maintain a reaction pressure of 1.8MPa for polymerization reaction to obtain a precursor resin.

[0048] Precursor resin data:

[0049] by F 19 NMR and IR analysis confirmed that it was a ternary polymer. According to the integrated value of fluorine NMR, the molar percentage of tetrafluoroethylene contained in the polymer structure was 58.1%. 2 =CF-O-CF 2 -CF 2 -SO 2 F) The molar percentage is 33.4%, containing sulfonyl fluoride group enyl ether monomer (CF 2 =CF-OCF 2 -CF(CF 3 )-O-CF 2 CF 2 SO 2 F) The mole percentage is 8.5%, in the overall resin -SO ...

Embodiment 3

[0054] Embodiment 3: a kind of preparation method of perfluorinated ion exchange resin comprises the following steps:

[0055]Clean the reactor and add 6L of deionized water, 100ml of an aqueous solution containing 10g of sodium dodecylsulfonate, start the stirring device, vacuumize, and replace with high-purity nitrogen for three times. After testing, the oxygen content in the reactor is below 10ppm , vacuumize, add 1000g sulfonyl fluoride pendant vinyl ether monomer 1 (CF 2 =CF-O-CF 2 -CF 2 -SO 2 After F), fill the reaction kettle with tetrafluoroethylene monomer pressure to 2.0MPa, raise the temperature to 55°C, and add 100g of azodibutylamidine hydrochloride aqueous solution (initiator solution) with a mass concentration of 4.5% with a metering pump , to initiate the polymerization reaction, continue to feed tetrafluoroethylene monomer to keep the reaction pressure at 2.0MPa, add 30g of initiator solution to the system every 30min, stop adding the initiator after reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com