Preparation method of polyacrylonitrile-based carbon nanofibers

A carbon nanofiber, polyacrylonitrile-based technology, which is applied in the field of carbon nanofiber preparation, can solve the problems of low spinning efficiency and few large-scale production equipment, and achieve the effects of good crystal shape, fine fiber diameter and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

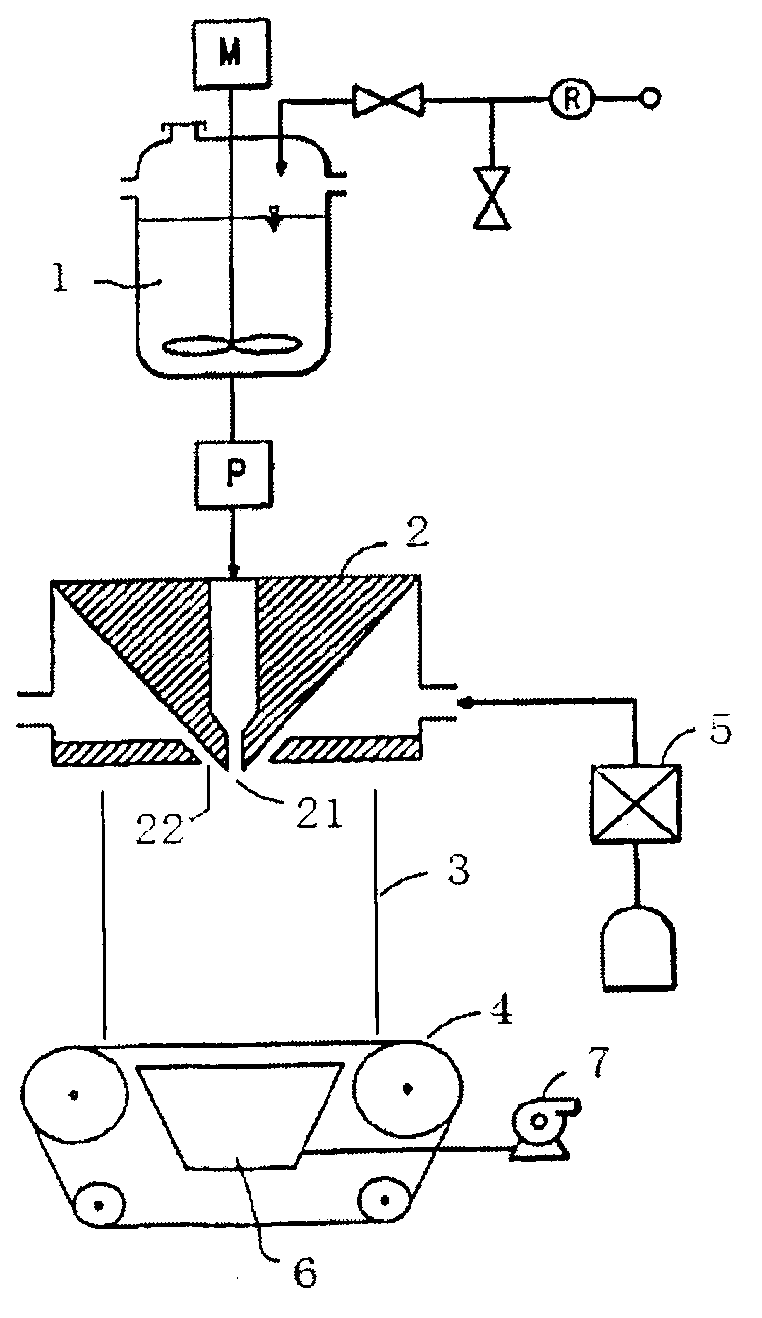

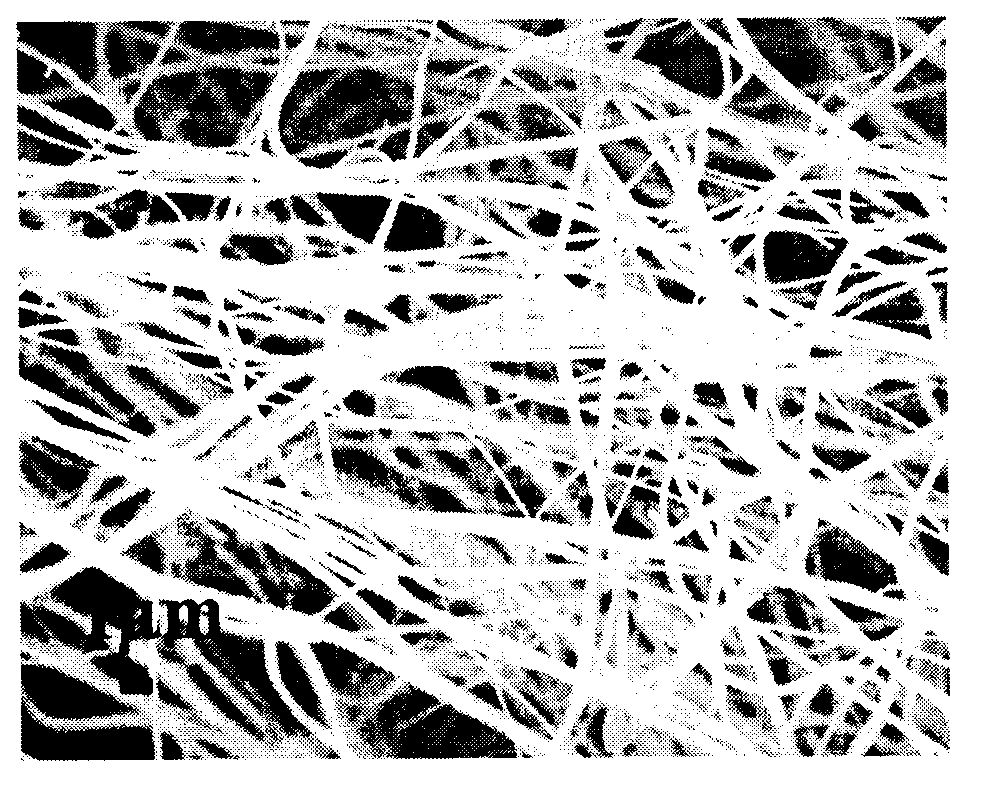

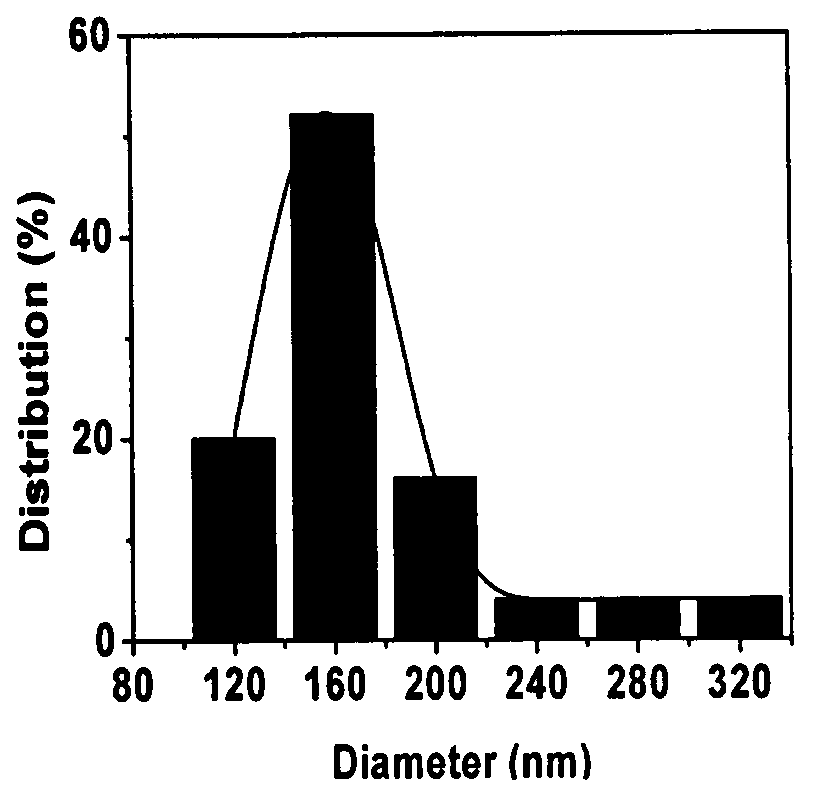

[0023] The invention discloses a method for preparing carbon nanofibers (referred to as the preparation method, see Figure 1). The process steps are as follows: dissolving polyacrylonitrile in a solvent to form a spinning solution, and then supplying the spinning solution to the containing The spinning die 2 with a series of spinning holes makes the spinning solution extrude from the spinning holes 21 of the spinning die 2 to form a thin stream of spinning solution; at the same time, at least one high-speed jet airflow enters the spinning die 2, and through the air gap 12 of the spinneret 2 at a spray angle of 0-30 degrees to blow the extruded spinning solution trickle; the high-speed jet airflow realizes the stretching and refinement of the spinning solution trickle, while Accelerate the volatilization of the solvent in the spinning solution to form polyacrylonitrile nanofibers; place the polyacrylonitrile nanofibers in an oxidation furnace and pre-oxidize in an oxygen environm...

Embodiment 1

[0031] (1) Preparation of spinning solution: Dissolve polyacrylonitrile with a viscosity average molecular weight of 90,000 into N,N-dimethylformamide at a mass fraction of 12%, and stir until the mixture is uniform to make a spinning solution;

[0032] (2) Solution jet spinning method to prepare polyacrylonitrile nanofibers: the spinning solution is supplied to spinneret 2 through a metering pump at a rate of 12mL / h / spinning hole, so that the spinning solution is discharged from spinneret 2 Extruded into the spinneret hole 21 to form a fine stream of spinning solution; at the same time, two high-speed jet air streams with a temperature of 40°C are used to blow the extruded spinning solution stream at a jet angle of 30° through the air gap 12, and the airflow speed is controlled 800 times the extrusion speed of the solution trickle, the high-speed air stream stretches the solution trickle and promotes solvent volatilization to form polyacrylonitrile nanofibers;

[0033] (3) Pre-oxi...

Embodiment 2

[0037] (1) Preparation of spinning solution: Dissolve polyacrylonitrile with a viscosity average molecular weight of 120,000 into N,N-dimethylacetamide at a mass fraction of 10%, and stir until the mixture is uniform to make a spinning solution;

[0038] (2) Solution jet spinning method to prepare polyacrylonitrile nanofibers: the spinning solution is supplied to the spinneret 2 through a metering pump at a rate of 22mL / h / spinning hole, so that the spinning solution is discharged from the spinneret 2 Extruded into the spinneret hole 21 to form a fine stream of spinning solution; at the same time, two high-speed jet air streams with a temperature of 50°C are used to blow the extruded spinning solution stream at a jet angle of 15° through the air gap 12. The air flow speed is controlled It is 1200 times the extrusion speed of the solution trickle, and the high-speed air stream stretches the solution trickle and promotes the volatilization of the solvent to form polyacrylonitrile nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com