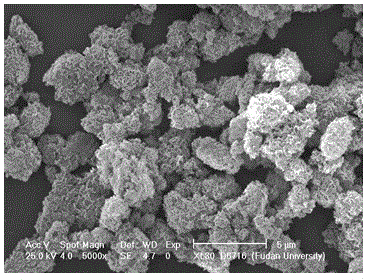

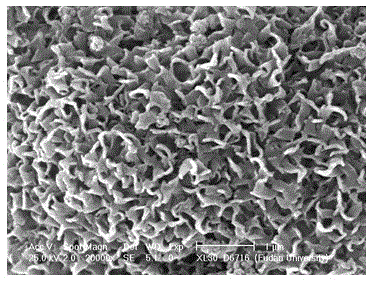

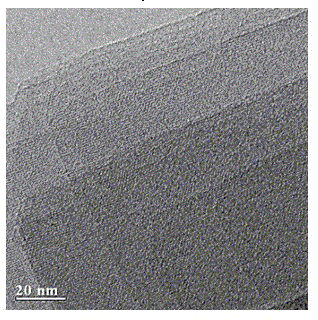

Method for synthesizing novel thin layer ZSM-5 zeolite with boron-containing framework

A technology of ZSM-5 and synthesis method, applied in the directions of borocarbonane silicone crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as affecting application, achieve adjustable surface acid properties and broad application prospects , the effect is larger than the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] a. Synthesis of double quaternary ammonium salt template

[0041]Add 1-bromocarbodococane and N,N,N',N'-tetramethyl-1,6-hexanediamine into a round bottom flask, add 100ml of a mixed solution of toluene and acetonitrile, in which bromine The molar ratio of alkanes and diamines is 1:10, and toluene / acetonitrile (v / v)=1:1. The flask was placed in an oil bath under reflux at 100°C for 12 hours. The resulting product was washed 3 times with cold diethyl ether, and dried under vacuum at 50°C for 18 hours to obtain a white waxy solid C 22 h 45 -N(CH 3 ) 2 -C 6 h 12 -N(CH 3 ) 2 Br, marked C 22-6-0 Br.

[0042] the resulting C 22-6-0 Add Br, 1-bromo-n-hexane and 100ml acetonitrile into the round bottom flask, where C 22-6-0 The molar ratio of Br and n-bromohexane is 1:3. The flask was placed in an oil bath under reflux at 100°C for 24 hours. The resulting product was washed 3 times with cold ether, and dried under vacuum at 50°C for 18 hours to obtain a white wax-l...

Embodiment 2

[0051] In the preparation process of the catalyst in this example, water glass was used as the silicon source, aluminum sulfate was used as the aluminum source, and boric acid was used as the boron source. Template agent and synthesis steps are exactly the same as in Example 1, and the obtained catalyst is marked as L-BZSM5-2.

Embodiment 3

[0053] In the preparation process of the catalyst in this example, silica sol was used as the silicon source, aluminum nitrate was used as the aluminum source, and sodium borate was used as the boron source. Template agent and synthesis steps are exactly the same as in Example 1, and the obtained catalyst is marked as L-BZSM5-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com