Macroelement soluble fertilizer and preparation method thereof

A technology of microelement fertilizer and macroelement, which is applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of scarcity and unfavorable situation, and achieve the effects of high nutrient content, reduced evaporation, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

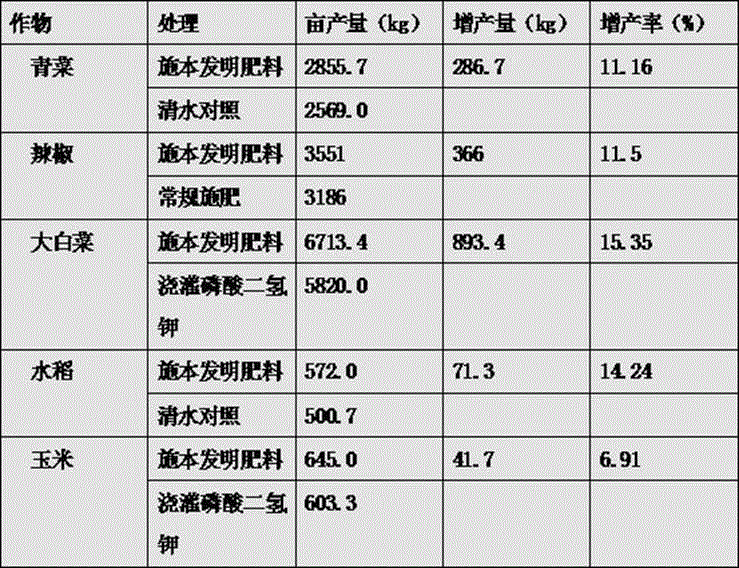

Examples

Embodiment 1

[0020] A water-soluble fertilizer with a large number of elements is characterized in that the weight parts (kg) of its raw materials are: dipotassium hydrogen phosphate 55, phosphoric acid 6, urea 35, zinc chloride 1, instant boron 3, edetate disodium 2.5 , animal hair, feathers 1, ammonium nitrate 10, centipede powder 3, distiller's grains 4, eucalyptus leaves 6, sugarcane leaves 8, modified tree ash 3.5, trace element fertilizer 5 and water 65.

[0021] The preparation method is characterized in that it comprises the following steps:

[0022] (1) Weigh each raw material according to the weight of the constituent raw materials, first add animal hair, feathers, etc. to 3 (kg) 25-35% sulfuric acid and hydrolyze it at 60-80°C for 8-10 hours to generate amino acids, then add lime to it And, according to the ratio of 15:3-4, add 3-4 parts by weight of carboxymethyl cellulose for every 15 parts by weight of hydrolyzed solution, then add phosphoric acid, urea, trace element fertili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com