Method for producing semicoke by using pulverized coal

A technology for pulverized coal and semi-coke, applied in the field of semi-coke (blue carbon) production, can solve the problems of wear and tear of conveying equipment, difficult separation of tar, large amount of gas dust, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of semi-coke produced by pulverized coal, the ratio of each raw material component according to the mass percentage is:

[0021] Raw material pulverized coal 92%, coal tar medium temperature pitch 8%.

[0022] Production method: After mixing the raw coal powder and coal tar medium-temperature pitch in proportion, send it to a horizontal mixer, feed 0.4MPa saturated steam into the mixer and the spacer for kneading and mixing, and mix evenly and have a certain degree of plasticity. Discharged from the mixer, pressed into oval briquettes with a diameter of 35 mm by a double-roller forming machine, put into a kettle-type carbonization furnace for carbonization and carbonization, and the carbonization temperature is 720 ° C to obtain semi-coke.

[0023] The quality index of embodiment 1 gained semi-coke is as follows:

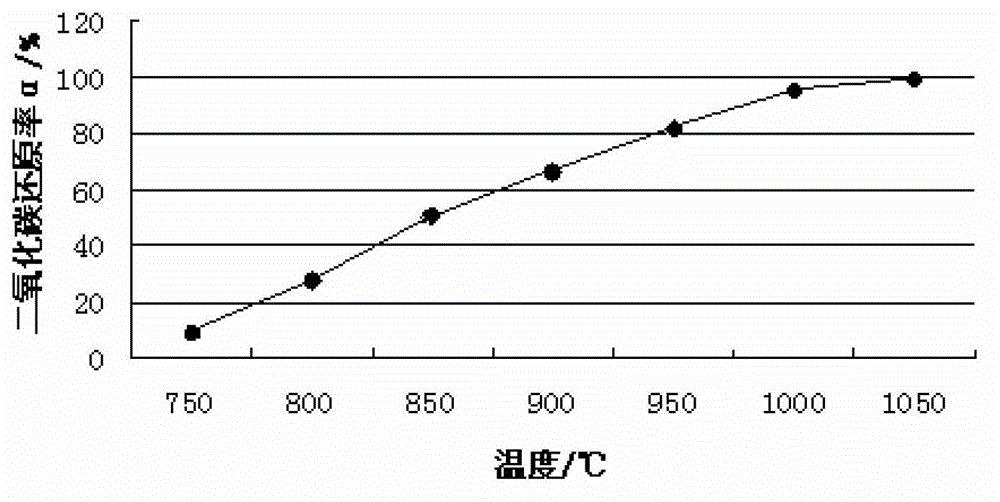

[0024] Ash (A d ) 6.91%, volatile matter (V daf ) 4.20%, sulfur (S t,,d ) 0.26%, specific resistance>109816 10 -6 Ω·m; high reactivity, semi-focu...

Embodiment 2

[0026] A kind of semi-coke produced by pulverized coal, the ratio of each raw material component according to the mass percentage is:

[0027] Raw coal powder 86%, caking coal 8%, coal tar medium temperature pitch 6%.

[0028] Production method is with embodiment 1.

[0029] The quality index of embodiment 2 gained semi-coke is as follows:

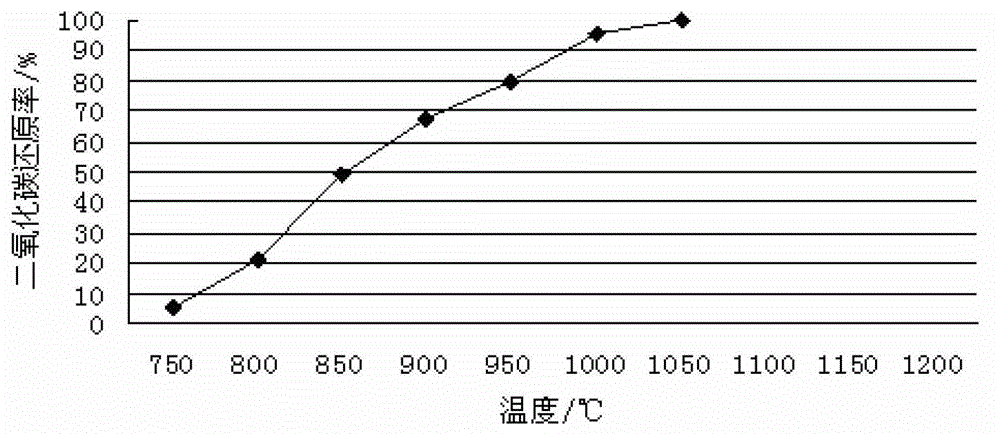

[0030] Ash (A d ) 8.31%, volatile matter (V daf ) 3.97%, sulfur (S t,,d ) 0.46%, specific resistance>108464 10 -6 Ω·m; high reactivity, the reactivity of semi-coke to CO2 see figure 2 . Drop strength: a single ball 1.83 meters free fall 10 times without breaking.

Embodiment 3

[0032] A kind of semi-coke produced by pulverized coal, the ratio of each raw material component according to the mass percentage is:

[0033] Raw coal powder 90%, caking coal 2%, binder 8%.

[0034] Production method is with embodiment 1.

[0035] The quality index of embodiment 3 gained semi-coke is as follows:

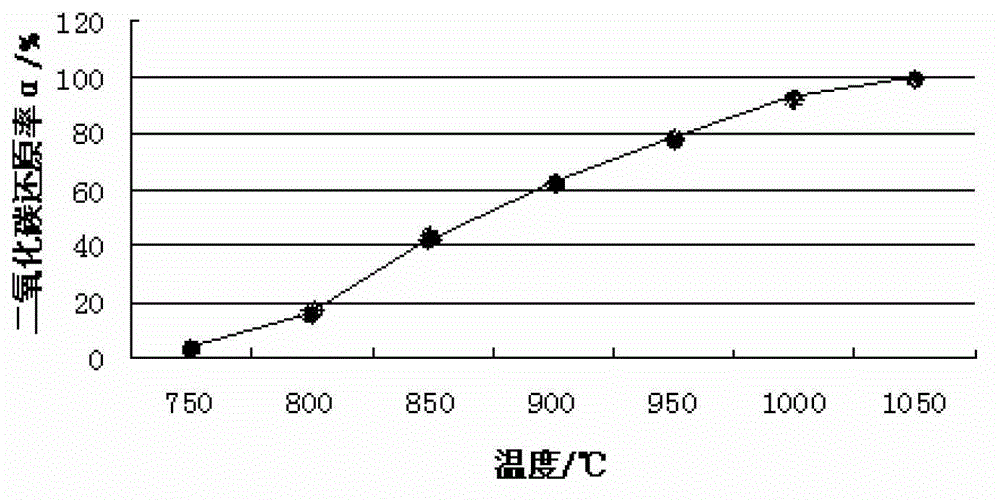

[0036] Ash (A d ) 7.89%, volatile matter (V daf ) 4.56%, sulfur (S t,,d ) 0.36%, specific resistance>108312 10 -6 Ω·m; high reactivity, the reactivity of semi-coke to CO2 see image 3 . Drop strength: a single ball 1.83 meters free fall 10 times without breaking.

[0037] In the above embodiments, the raw coal powder is one or more of long-flame coal, non-caking coal or weakly caking coal. Caking coal is 1 / 3 coking coal or fat coal, and the ash content is not more than 12%, and the sulfur is less than 1%. The softening point (ring and ball method) of coal tar medium-temperature pitch is 75°C to 90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com