Anode modifying material of polymer solar battery and modifying method

A solar cell and anode modification technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unstable anode interface, corrosion of anode ITO, and affecting the long-term stability of solar cells, etc., to achieve high photoelectric conversion efficiency and improve power efficiency. letter, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

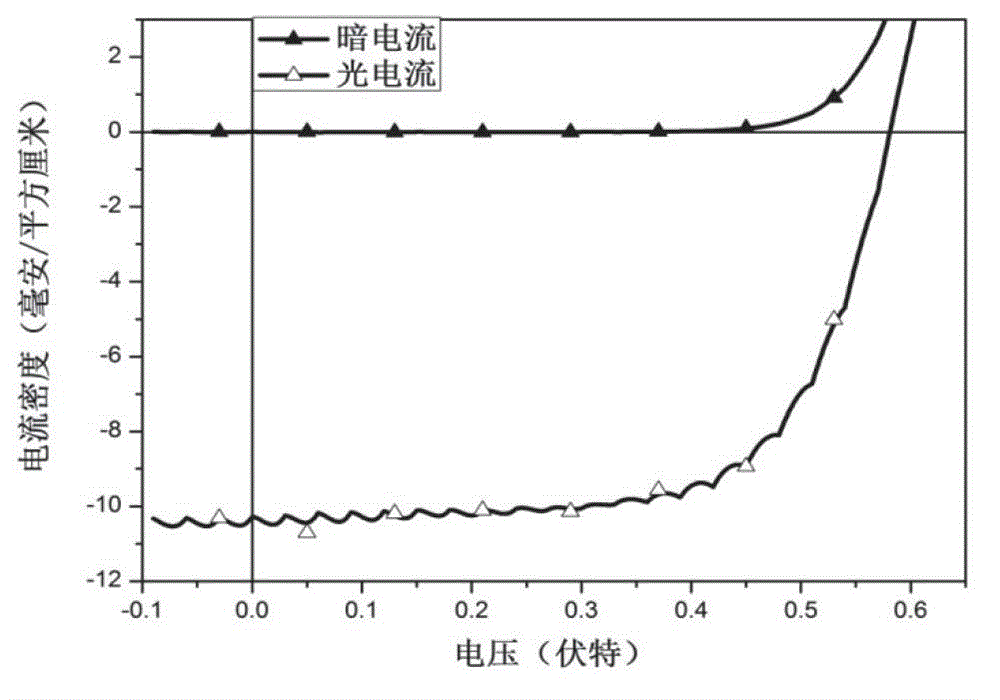

[0019] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, and dried with nitrogen, and the substrate was treated with UVO. Spin-coat a methyl rhenium trioxide isopropanol solution with a concentration of 1mg / ml at a rotating speed, place it in the air at room temperature for 25 minutes, bake it in the air at 110°C for 10 minutes, cool naturally, and then treat it with ultraviolet ozone (UVO) for 1 minute. Obtain the anode modification layer. Then 20mg / mL of P3HT and PC 60 The mixed solution of BM 1:1 (mass ratio) was directly spin-coated on the above-mentioned anode modification layer at a speed of 800 rpm as the photoelectric active layer. Finally, at 5×10 -5 20nm calcium and 100nm aluminum were vacuum evaporated under Pa to serve as the cathode. In the obtained polymer solar cell, the thickness of the methyl rhenium trioxide film was 100 Å...

Embodiment 2

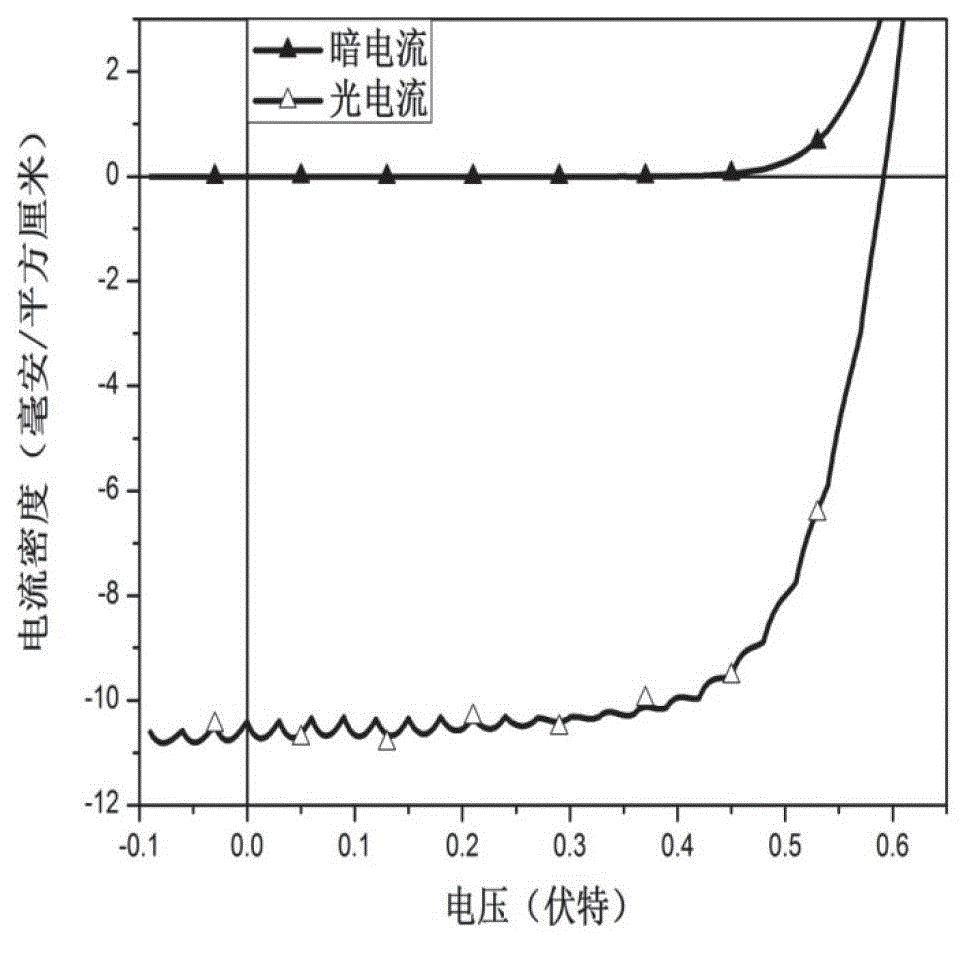

[0021] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, and dried with nitrogen, and the substrate was treated with UVO. Spin-coat a methyl rhenium trioxide isopropanol solution with a concentration of 10mg / ml at a rotating speed, place it in the air at room temperature for 25 minutes, bake it in the air at 110°C for 10 minutes, cool naturally, and then perform UVO treatment for 15 minutes to obtain an anode modification layer . Then 20mg / mL of P3HT and PC 70 The mixed solution of BM 1:1 (mass ratio) was directly spin-coated on the above-mentioned anode modification layer at a speed of 800 rpm as the photoelectric active layer. Finally, at 5×10 -5 20nm calcium and 100nm aluminum were vacuum evaporated under Pa to serve as the cathode. In the obtained polymer solar cell, the thickness of the methyl rhenium trioxide film was 100 Å. The prep...

Embodiment 3

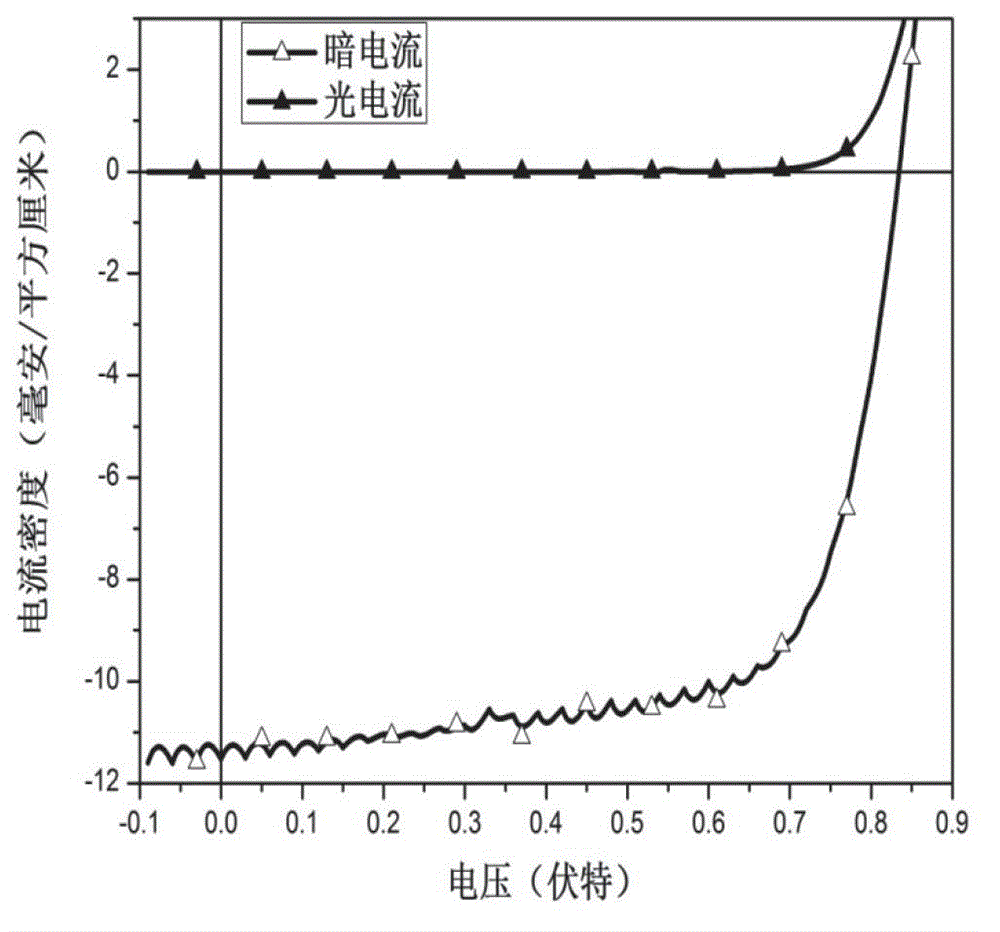

[0023] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol in sequence, and dried with nitrogen, and the substrate was treated with UVO. Spin-coat a methyl rhenium trioxide isopropanol solution with a concentration of 7.5mg / ml at a rotating speed, place it in the air at room temperature for 25 minutes, bake it in the air at 110°C for 10 minutes, cool naturally, and then perform UVO treatment for 1 hour to obtain anodic modification. layer. Then 17mg / mL of P3HT and IC 60 The mixed solution of BA 1:1 (mass ratio) was directly spin-coated on the above-mentioned anode modification layer at 800 rpm as the photoelectric active layer. Finally, at 5×10 -5 20nm calcium and 100nm aluminum were vacuum evaporated under Pa to serve as the cathode. In the obtained polymer solar cell, the thickness of the methyl rhenium trioxide film was 100 Å. The prepared device has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com