Device for realizing powder high-density vibration compression moulding

A high-density, powder technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of poor quality control of fine powder compacts, insufficient preparation, unstable powder product quality, etc., to achieve Process optimization and automation of production, improved quality and performance, uniform internal density and stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

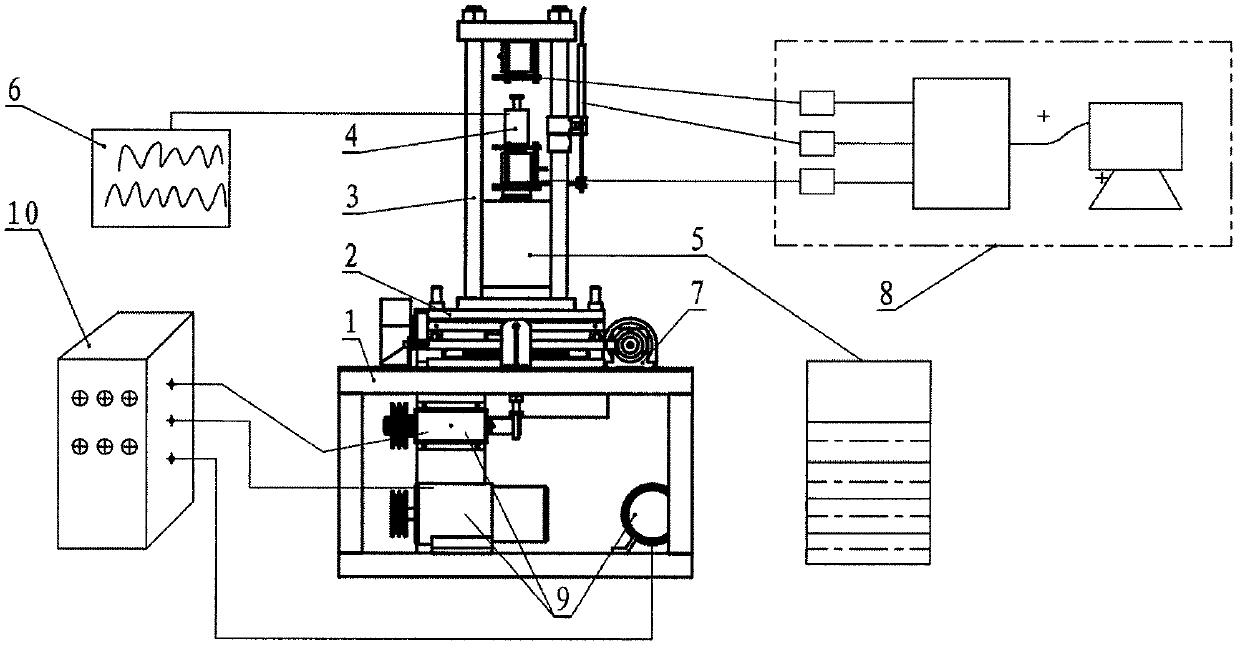

[0020] The method for manufacturing the equipment for realizing powder high-density vibratory pressure forming according to the embodiment will be described in detail with reference to the accompanying drawings.

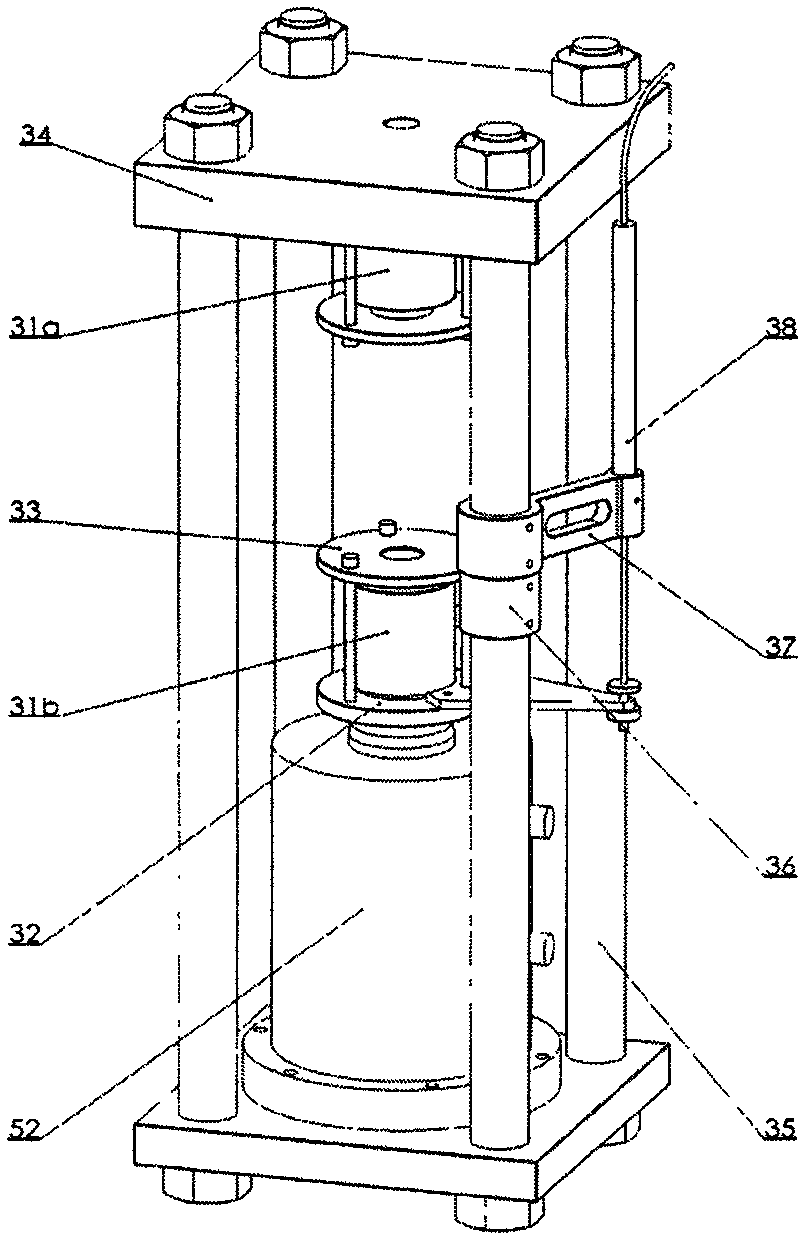

[0021] This embodiment refers to the attached figure 1 As shown, the mechanical vibrating device (2), the ultrasonic vibrating device (6) and the bearing seat (7) are respectively located at different positions of the machine base (1), and the oil cylinder and the mold assembly ( 4) respectively located on the mechanical vibrating device (2), one end of the data acquisition system (8) is respectively connected with the pressure sensors (31a, b) and displacement sensors (37) at both ends of the mold assembly (4), and the other end is connected with the remote computer The terminal is connected.

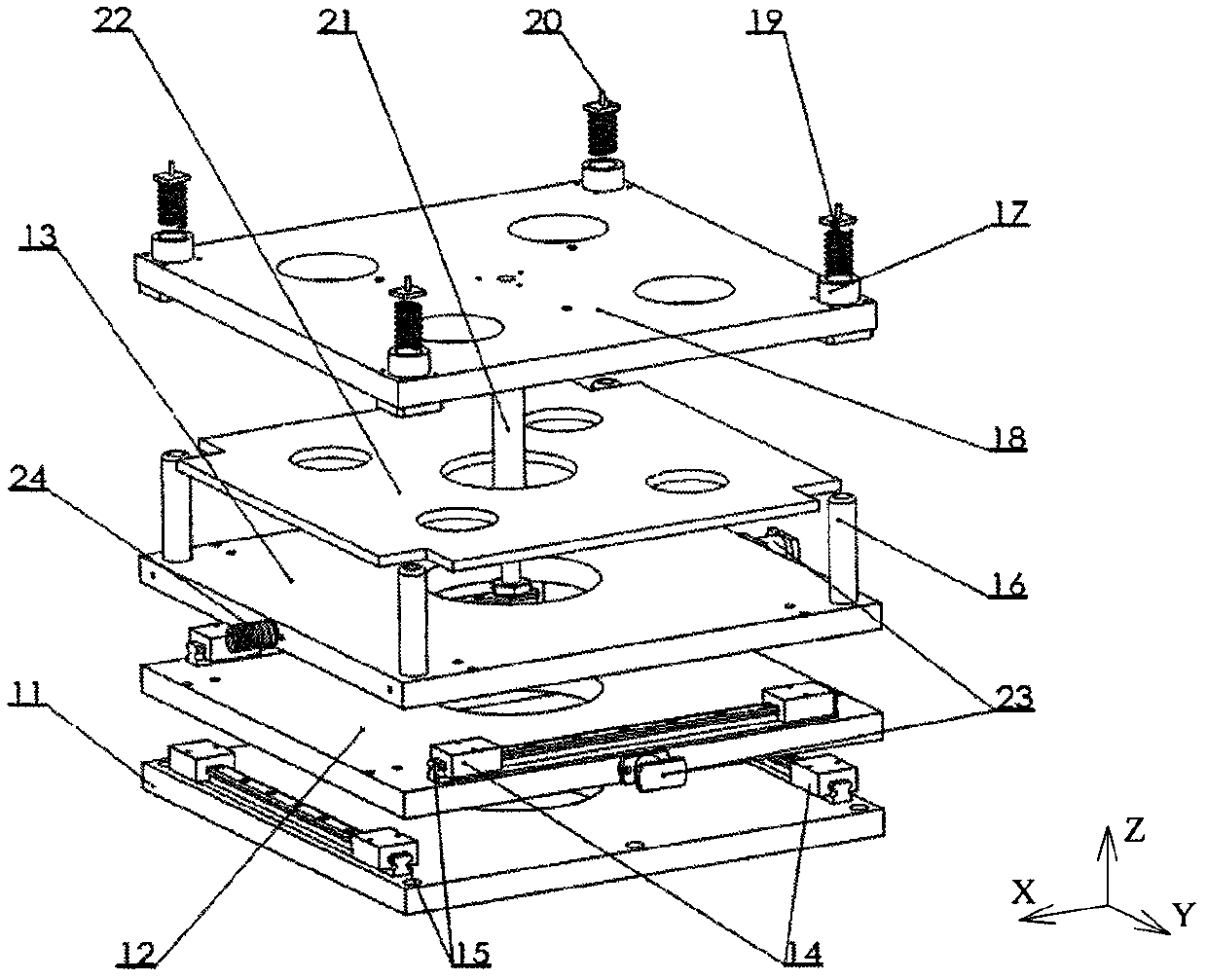

[0022] figure 2The structure of the mechanical vibrating device shown: the X guide plate (13) and the Y guide plate (12) of the two horizontal directions on the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com