Preparation method of stannic oxide micro-nano materials based on APCVD (atmospheric pressure chemical vapor deposition) method

A technology of atmospheric pressure chemical vapor phase and tin dioxide, applied in the direction of tin oxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of high cost and difficult material growth, and achieve low cost and high quality equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

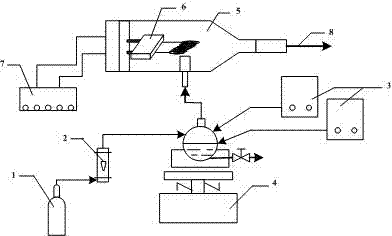

Method used

Image

Examples

Embodiment 1

[0037] In the first step, mix 1 mg of dry graphene oxide with a small amount of ethanol, grind it into a paste, and evenly coat it on the resistance ring, and put the resistance ring coated with graphene oxide into the muffle furnace for 300 o Calcined at C for 1 hour, after treatment, a uniform coating was formed on the resistance ring as a base for depositing tin dioxide material.

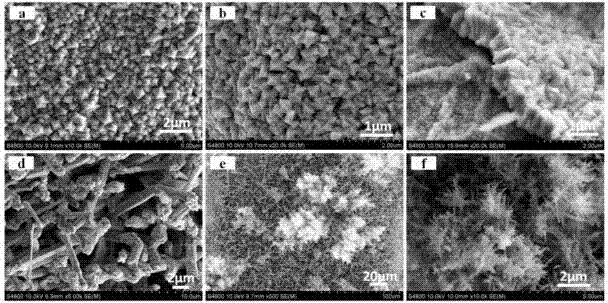

[0038] In the second step, put the resistance coil coated with the substrate into the quartz reaction chamber, first pass through the argon protective gas at a flow rate of 100mL / min for 15 minutes, and then mix the 0.19mg / mL stannous chloride solution with potassium borohydride The solution was mixed at a flow rate of 1.5mL / min to generate tin hydrogen online, and was brought into the reaction chamber by argon. Turn on electricity to heat the resistor coil to 580 o C. After the precursor is deposited on the substrate for 60 minutes, stop generating tin hydrogen and turn off the power supply, an...

Embodiment 2

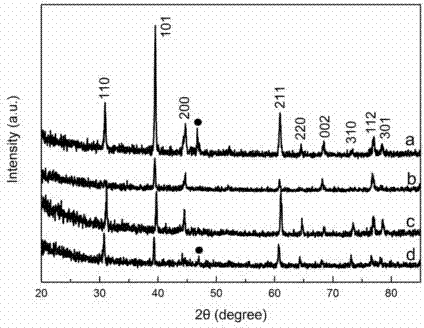

[0040] By the preparation method of embodiment 1, just change deposition temperature into 540 o C, the prepared tin dioxide material is a square nanorod structure with a width of about 400 nanometers and a length of about 1.5 microns. The SEM photo of the product is as follows figure 2 -b, shown in 2-c, the XRD pattern of the product is as follows image 3 -b shown.

Embodiment 3

[0042] By the preparation method of embodiment 1, just change the temperature of deposition into 500 o C, the structure of the tin dioxide material prepared, the size are similar to the material prepared by Example 2, and the SEM photo of the product is as follows figure 2 As shown in -a, the XRD pattern of the product is as follows image 3 -a shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com