Graphene and rare earth up-conversion fluorescent composite material and preparation method thereof

A technology of rare earth up-conversion and composite materials, which is applied in the field of preparation of graphene and rare earth up-conversion fluorescent composite materials. It can solve problems such as solutions or routes that have not been reported, and achieve stable reaction conditions, broad application prospects, and simple processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach ( 1

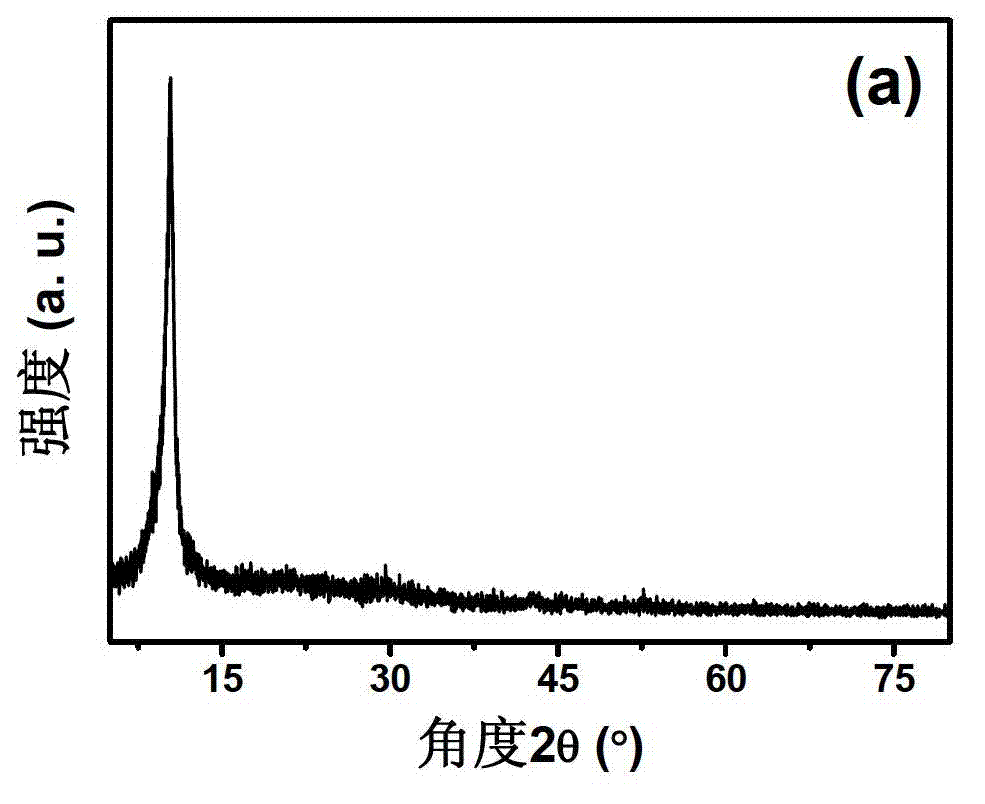

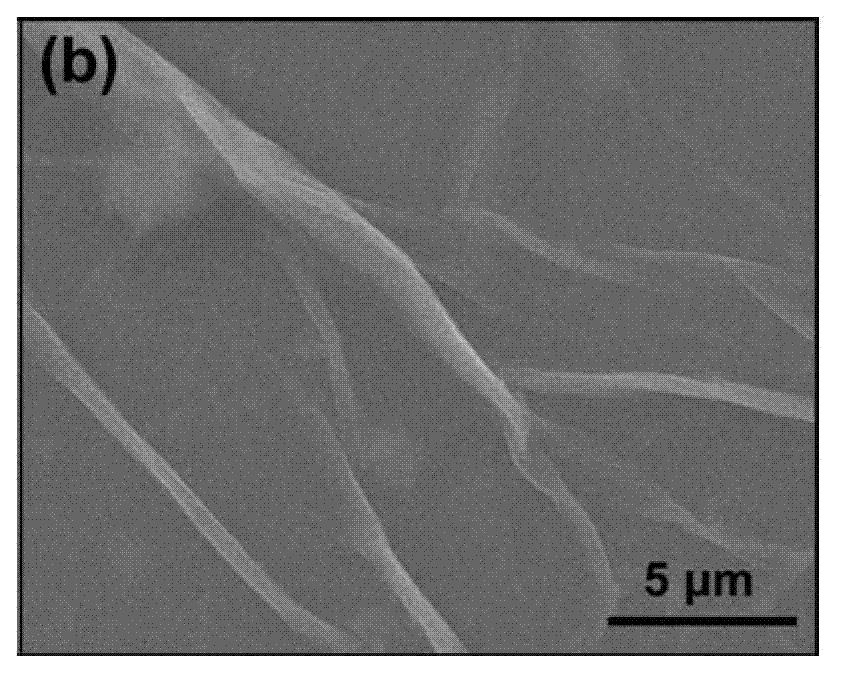

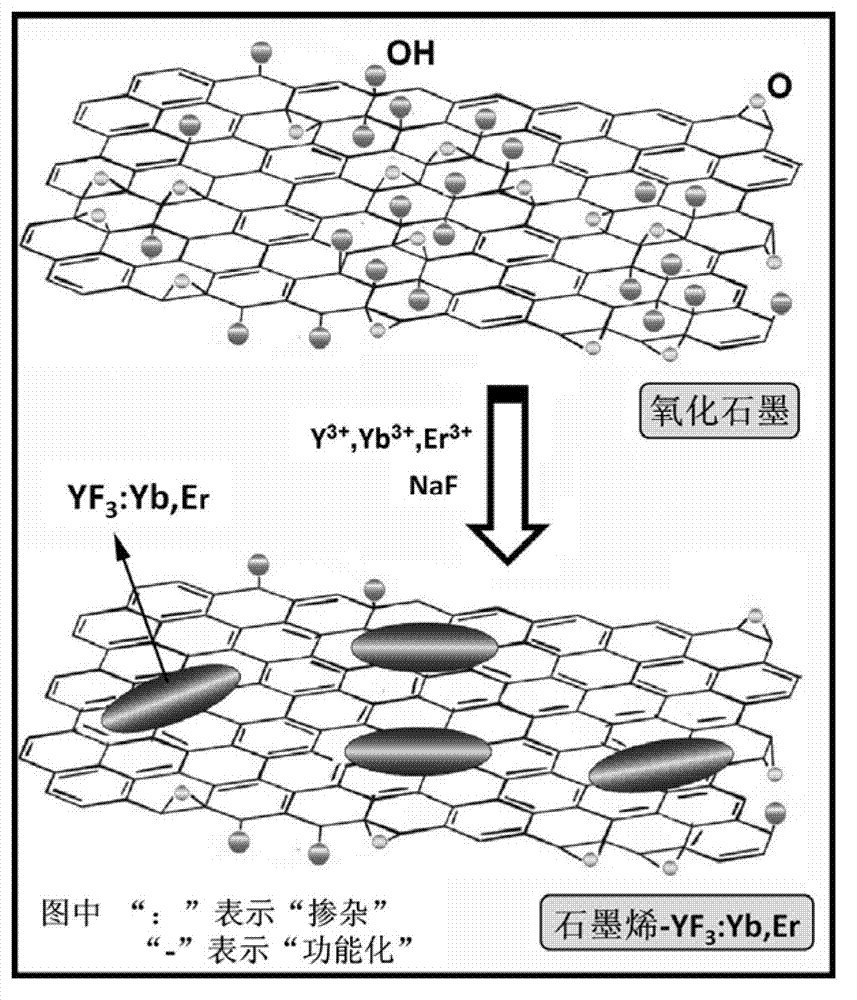

[0021] Graphite oxide was prepared by the Hummer method using graphite powder as the raw material for the next step of compounding and as a comparison material. 5.9mg of graphite oxide was ultrasonically dispersed in 60mL of water, and the total molar mass was 0.05mmol of Y(NO 3 ), Yb(NO 3 ) and Er(NO 3 ) was added to the above-mentioned graphite oxide dispersion in a stoichiometric ratio of 78:20:2. Add 0.025g NaF, stir for 10min, transfer to a 100mL reactor, and react at 200°C for 24h. Naturally cool to room temperature, centrifuge and wash twice with deionized water to obtain graphene and phosphor YF 3 : Composites of Yb, Tm, denoted as graphene-YF 3 :Yb,Er, where "-" means functionalization, ":" means doping, "α" means α phase.

specific Embodiment approach ( 2

[0022] 5.9mg of graphite oxide was ultrasonically dispersed in 60mL of water, and the total molar mass was 0.05mmol of Y(NO 3 ), Yb(NO 3 ) and Er(NO 3) was added to the above-mentioned graphite oxide dispersion in a stoichiometric ratio of 78:20:2. Add 0.108g NaF, stir for 10min, then transfer to a 100mL reactor, and react at 200°C for 24h. Naturally cooled to room temperature, centrifuged and washed twice with deionized water, then graphene and phosphor α-phase NaYF were obtained 4 : Composites of Yb, Er, expressed as graphene-(α)NaYF 4 : Yb, Er.

specific Embodiment approach ( 3

[0023] 75mg of graphite oxide was ultrasonically dispersed in 24mL of water, and a total molar mass of 1mmol of Y(NO 3 ), Yb(NO 3 ) and Er(NO 3 ) was added to the above-mentioned graphite oxide dispersion in a stoichiometric ratio of 78:20:2. Add 0.8823g of sodium citrate, stir for 5min, then add 24mL of ethanol, and add dropwise 24mL of a solution of 0.42g of NaF in water and ethanol (volume ratio: 1) under vigorous stirring. Adjust the pH value to 3, transfer to a 100mL reactor, and react at 240°C for 4h. Obtaining graphene and β-phase NaYF 4 : Composites of Yb, Er phosphors, expressed as graphene-(β)NaYF 4 : Yb, Er.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com