Bacillus, bacterial agent, preparation method and applications thereof

A technology of bacillus and bacterial agents, applied in the field of microorganisms, to achieve the effects of simple and easy preparation methods, strong environmental adaptability and environmental friendliness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

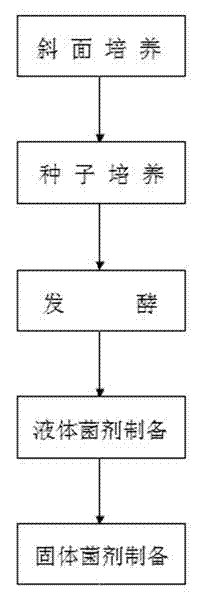

[0042] The preparation method of the bacterial agent with bacillus as the active ingredient of the present invention comprises the steps of inclined plane culture, seed cultivation, fermentation, liquid bacterial agent preparation, and solid bacterial agent preparation steps, specifically comprising:

[0043] A, slant culture: Bacillus amyloliquefaciens ( Bacillus amyloliquefaciens ) WY11 was inoculated on the slant medium, and cultured at 28-30°C for 48 hours to obtain slant strains;

[0044] B. Seed culture: inoculate the slant strains into the liquid medium, and cultivate them at a temperature of 28-34°C for 18-24 hours to obtain liquid-fermented seeds;

[0045] C. Fermentation: inoculate the liquid fermented seeds into the fermenter according to the amount of 3~5% of the medium volume, cultivate at 28~34°C for 36~48h, the stirring speed is 120~150rpm, and the ventilation rate is 5~10%, and the solution is obtained. Bacillus amylogenus WY11 fermentation broth;

[0046] D. ...

Embodiment 1

[0064] ——Preparation of preparations with Bacillus amyloliquefaciens WY11 as the active ingredient

[0065] A, slant culture: Bacillus amyloliquefaciens ( Bacillus amyloliquefaciens ) WY11 was inoculated on the agar medium and cultured at 30°C for 48 hours to obtain slant strains.

[0066] B. Seed culture: the above-mentioned slant strains were inserted into the seed culture solution, cultured at 30° C. for 24 hours, and the rotation speed of the shaker flask was 150 rpm to obtain liquid fermented seeds. Ingredients of seed culture solution: 3% beef extract, 0.5% peptone, 0.5% sodium chloride, the rest is water, and the pH value is 7.

[0067] C. Liquid fermentation culture: according to the inoculum amount of 5%, inoculate the above-mentioned liquid fermentation seeds into a fermenter equipped with a liquid fermentation system, and cultivate them at 32°C for 48 hours, with a stirring speed of 150rpm and an air flow of 8%, to obtain starch decomposing Bacillus WY11 fermenta...

Embodiment 2

[0070] ——Preparation of preparations with Bacillus amyloliquefaciens WY11 as the active ingredient

[0071] It is basically the same as Example 1, except that: A, the temperature of slant culture is 28°C. B. The temperature of the seed culture is 28° C., the time is 18 hours, and the rotation speed of the shaker flask is 120 rpm. The pH value of the seed culture solution was 6.5. C. The liquid fermentation culture is inoculated at 3%, the temperature is 28°C, the time is 36h, the stirring speed is 120rpm, and the ventilation rate is 5%. The components of the fermentation medium are: 1% bean cake powder, 1% soluble starch, 0.5% beef extract, NaCNO 3 0.02%, CaCO 3 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com