Cathode plate anticorrosive coating for zinc electrowinning and preparation method of cathode plate anticorrosive coating

An anti-corrosion coating, cathode plate technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of short life extension, easy to be corroded, reduce the service life of plates, etc., to improve corrosion resistance, simple and easy to operate , the effect of reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

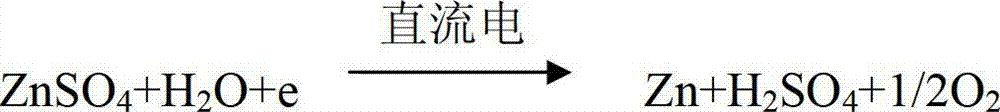

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Surface treatment of the cathode plate: Firstly, sandblast the surface of the cathode plate by dry spraying, then wash it with alkali with a volume concentration of 6% sodium hydroxide solution, and then pickle it with a volume concentration of 15% nitric acid solution. To remove the oil and oxide film on the surface of the cathode plate, and increase the roughness of the plate surface.

[0027] (2) Spraying: Spray anti-corrosion paint on the surface of the cathode plate. First spray the primer, the primer is epoxy modified paint, epoxy zinc yellow primer, the weight ratio of paint and curing agent is 5:1, spray 2 coats by spraying, the thickness can reach 100μm, and then place Bake in a blast drying oven at 60°C. After the paint is completely dry, spray the middle layer; the middle layer is furan paint, and the weight ratio of it to the curing agent is 5:1. Spray 2 coats by spraying, and the thickness can reach 200μm , still placed in a blast drying oven at 60°C a...

Embodiment 2

[0029] (1) Surface treatment of the cathode plate: Firstly, sandblast the surface of the cathode plate by dry spraying, then wash it with alkali with a concentration of 8% sodium hydroxide solution, and pickle with a solution of nitric acid with a concentration of 20% by weight and volume. Remove the oil and oxide film on the surface of the cathode plate, and increase the roughness of the plate surface.

[0030] (2) Spraying: Spray anti-corrosion paint on the surface of the cathode plate. First spray the primer, the primer is epoxy modified paint, epoxy zinc yellow primer, the weight ratio of paint and curing agent is 8:1, spray 2 coats by spraying, the thickness can reach 200μm, and then place Bake in a blast drying oven at 60°C. After the paint is completely dry, spray the middle layer; the middle layer is a silicone modified resin paint, and the weight ratio of it to the curing agent is 10:1. Spray 2 coats by spraying. The thickness can reach 400μm, and it is still baked i...

Embodiment 3

[0032] (1) Surface treatment of the cathode plate: Firstly, sandblast the surface of the cathode plate by dry spraying, then wash it with alkali with a volume concentration of 7% sodium hydroxide solution, and then pickle it with a volume concentration of 17.5% nitric acid solution. To remove the oil and oxide film on the surface of the cathode plate, and increase the roughness of the plate surface.

[0033] (2) Spraying: Spray anti-corrosion paint on the surface of the cathode plate. First spray the primer, the primer is epoxy modified paint, epoxy zinc yellow primer, the weight ratio of paint and curing agent is 6:1, spray 2 coats by spraying, the thickness can reach 150μm, and then place Bake in a blast drying oven at 60°C. After the paint is completely dry, spray the middle layer; the middle layer is vinyl resin plus glass flakes, and the weight ratio of it to the curing agent is 7.5:1. Spray 2 coats by spraying. The thickness can reach 300μm, and it is still baked in a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com