Composite microneedle array including nanostructures thereon

A microneedle array, nanostructure technology, applied in fields such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0177] A variety of different molds are prepared using photolithographic techniques similar to those used to design and fabricate circuits. The individual process steps are generally known and described in the art.

[0178] Initially, silicon substrates were prepared by cleaning with acetone, methanol, and isopropanol, and then a 258 nanometer (nm) silicon dioxide layer was deposited according to a chemical vapor deposition process.

[0179] Each substrate was patterned by an electron beam exposure patterning process known in the art using a JEOL JBX-9300FSEBL system. The process conditions are as follows:

[0180] Beam current=11nA

[0181] Acceleration voltage = 100kV

[0182] Shooting pitch=14nm

[0183] Dose=260μC / cm 2

[0184] Resist = ZEP520A, ~330nm thickness

[0185] Developer = n-pentyl acetate

[0186] Developing time = 2 minutes of immersion, 30 seconds followed by isopropanol rinse.

[0187] The silicon dioxide etch is then performed by STS Advanced Oxide ...

example 2

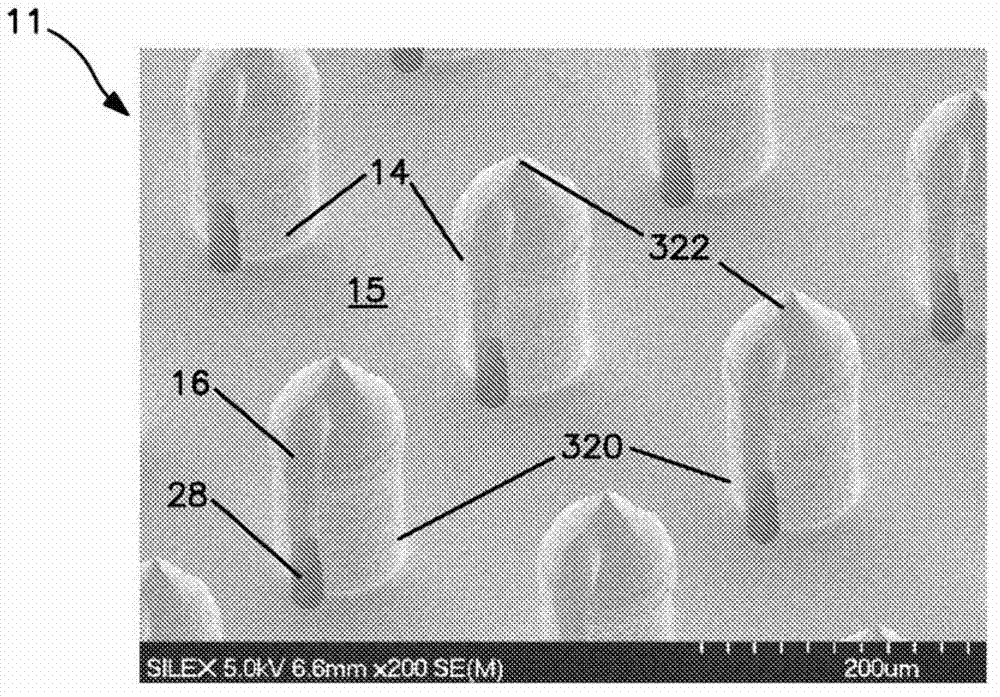

[0201] Films were formed as described in Example 1, including various patterns, polystyrene (PS) or polypropylene (PP) formed. The underlying substrate thickness varies. The patterns utilized were DN2, DN3 or DN4 using the formation process described in Example 1. The patterned die is varied in hole depth and feature pitch to form a variety of different sized features in a specified pattern. Sample 8 (designated BB1 ) was formed by using a 0.6 μm microporous polycarbonate filter as a mold. A 25 μm polypropylene film was placed on top of the filter and then heated to melt to enable the polypropylene to flow into the pores of the filter. The mold was then cooled and the polycarbonate mold was dissolved by using dichloromethane solvent.

[0202] The resulting SEM is shown in Figure 28-36 , and the characteristics of the films formed are summarized in Table 3 below.

[0203] table 3

[0204]

[0205] 1 Pattern features are shown in the accompanying drawings

[0206] 2...

example 3

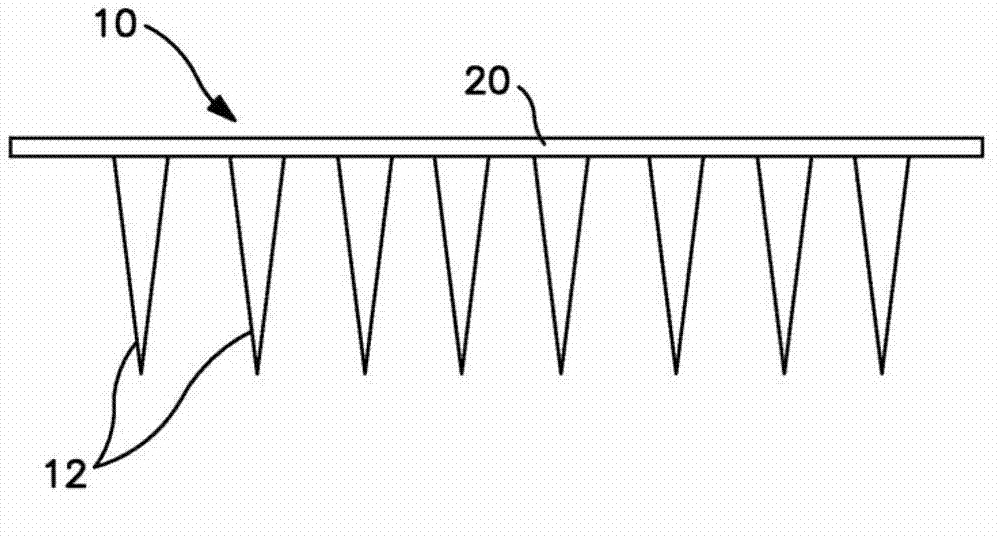

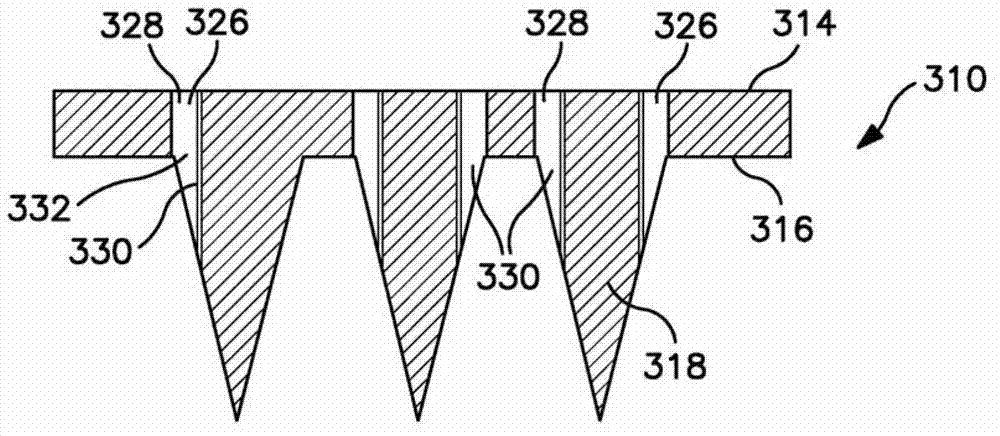

[0216] An array of microneedles is formed including a cover film defining a nanopatterned surface. Initially, arrays of microneedles are formed on silicon wafers through a photolithography process. Each needle includes two oppositely positioned side channels aligned with a perforation in the base of the needle.

[0217] Microneedles are formed on silicon substrates according to typical micromachining processes. The sheet is coated with a resist and / or oxide layer, followed by selective etching (oxide etch, DRIE etch, iso etch), debonding, deoxidation, and photolithographic techniques (e.g., iso lithography, aperture photolithography) according to standard methods. lithography, slit lithography) to form microneedle arrays.

[0218] After forming the microneedle array, a 5 μm polypropylene film including the DN2 pattern formed thereon, as described in Example 1 and characterized in Sample 2 of Table 3, was laid on the microneedle array. The sheet / film structure was kept in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com