Probenecid purification method

A purification method, technology of probenecid, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve problems such as hazards to environmental operation workers, difficulty in product recycling, and many processes, so as to reduce production costs and Environmental pollution, significant economic and social benefits, and the effect of simplifying the process of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

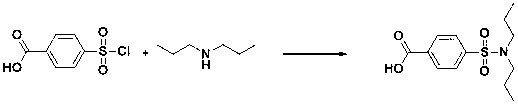

Image

Examples

Embodiment 1

[0030] Add 100 mL of pure water into a 250 ml three-necked flask, start stirring, add 28.5 g of crude probenecid, heat to 50-60°C, add 12.1 g of dipropylamine dropwise, and continue stirring at 50-60°C for 2 hours. Then the temperature was lowered to -20°C, and stirring was continued at -20°C for 4 hours.

[0031] Filter, add the filter cake to 80 mL of pure water, heat to 50-60°C, stir for 1 hour to dissolve it all. Add hydrochloric acid (31%) dropwise into the system to adjust p H=1-2, continue to stir for 1 hour, retest p When H is 1-2, the acidification is completed.

[0032] Filtrate, add the filter cake to 180 mL of pure water, heat to 30-40°C, stir and wash with water for 1 hour, filter while hot, and dry to obtain the finished product of probenecid. The yield is 92% based on the crude product of probenecid. High-performance liquid chromatography analysis, the content is greater than 99%, and the impurity content is less than 0.1%.

Embodiment 2

[0034] Add 100 mL of pure water into a 250 ml three-necked flask, start stirring, add 28.5 g of crude probenecid, heat to 50-60°C, add 5.4 g of dimethylamine dropwise, and continue stirring at 50-60°C for 2 hours. Then the temperature was lowered to -10°C, and stirring was continued at -10°C for 4 hours.

[0035] Filter, add the filter cake to 80 mL of pure water, heat to 50-60°C, stir for 1 hour to dissolve it all. Add hydrochloric acid (31%) dropwise into the system to adjust p H=1-2, continue to stir for 1 hour, retest p When H is 1-2, the acidification is completed.

[0036] Filtrate, add the filter cake to 180 mL of pure water, heat to 30-40°C, stir and wash with water for 1 hour, filter while hot, and dry to obtain the finished product of probenecid. The yield is 87% based on the crude product of probenecid. High-performance liquid chromatography analysis, the content is greater than 99%, and the impurity content is less than 0.1%.

Embodiment 3

[0038] Add 80 mL of pure water into a 250 ml three-necked flask, start stirring, add 28.5 g of crude probenecid, heat to 20-30°C, add 13.8 g of sodium hydroxide aqueous solution (32%) dropwise, and keep at 20-30°C Stir for 1 hour. Then the temperature was lowered to -20°C, and stirring was continued at -20°C for 6 hours.

[0039]Filter, add the filter cake to 80 mL of pure water, heat to 20-30°C, and stir for 1 hour to dissolve it completely. Add hydrochloric acid (31%) dropwise into the system to adjust p H=1-2, continue to stir for 1 hour, retest p When H is 1-2, the acidification is completed.

[0040] Filtrate, add the filter cake to 180 mL of pure water, heat to 30-40°C, stir and wash with water for 1 hour, filter while hot, and dry to obtain the finished product of probenecid. The yield is 90% based on the crude product of probenecid. High-performance liquid chromatography analysis, the content is greater than 99%, and the impurity content is less than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com